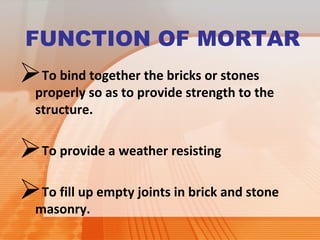

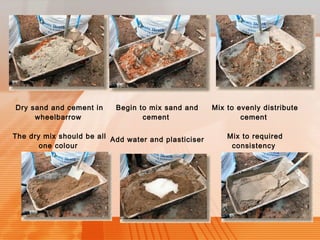

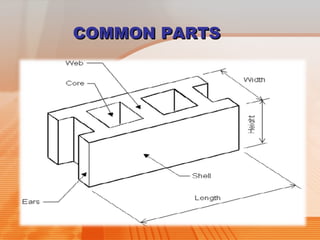

The document discusses mortar and concrete hollow blocks. Mortar is made from a mixture of fine aggregate, water, and cement that is used to bind bricks or stones. Concrete hollow blocks are large rectangular bricks made primarily from cement, sand, and gravel. They have hollow cores which make them lighter and more insulating than solid blocks. The document outlines the production process and advantages of using concrete hollow blocks for construction.