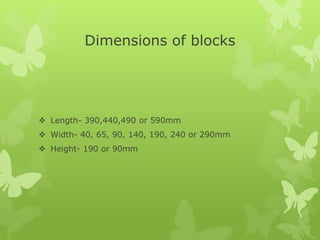

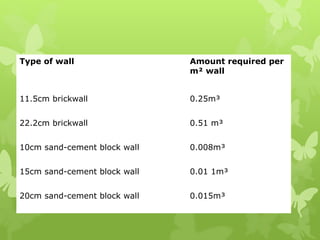

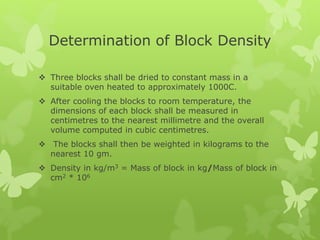

Cement and concrete blocks are alternative materials for masonry construction. Concrete blocks have a glossier finish and higher strength than cement blocks but are more expensive with greater dead weight. Blocks come in solid, hollow, and cellular forms and various dimensions. Using blocks requires less mortar and construction time than other materials like bricks, resulting in lower costs. Proper storage, testing of strength and dimensions, and reinforcement of the blocks can improve durability. Aluminium is also used for partitions and has an aesthetic appearance while being light, durable, and reusable.