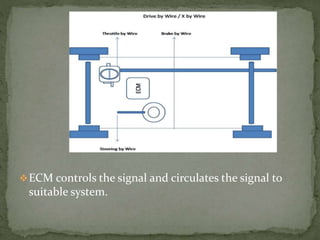

This document discusses drive by wire technology. It begins with an introduction and overview of the history and working principle. It then describes the different systems within drive by wire, including steer by wire, throttle by wire, and brake by wire. Each system replaces the traditional mechanical control systems with electronic sensors and actuators controlled by an engine control module. The advantages are more design flexibility, weight reduction, improved safety and performance, and potential for advanced driver assistance features. The document concludes by discussing future applications and trends toward more customizable control interfaces using drive by wire technology.