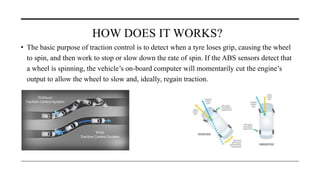

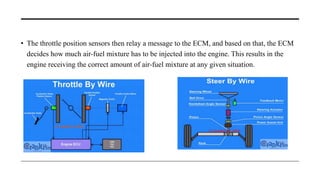

Traction control systems help maintain a car's grip on the road under slippery conditions by limiting wheel spin using sensors on each wheel. It works by cutting engine output if a wheel loses grip to allow it to slow down and regain traction. This improves safety but increases costs. Drive by wire technology similarly controls vehicle systems like acceleration electronically instead of mechanically, reducing weight and improving accuracy but is more expensive and prone to software issues. Both systems ultimately aim to improve vehicle handling and safety during poor traction.