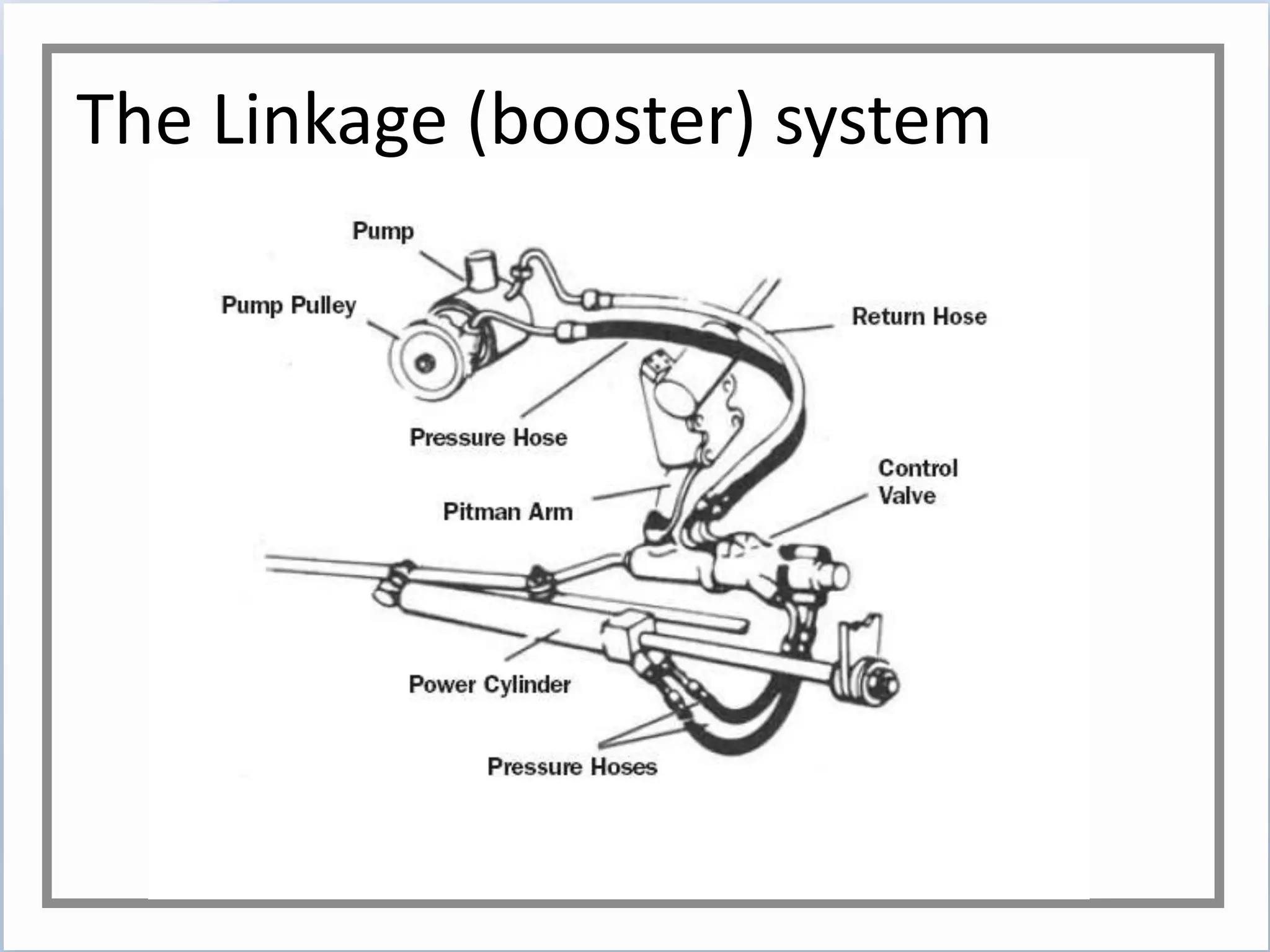

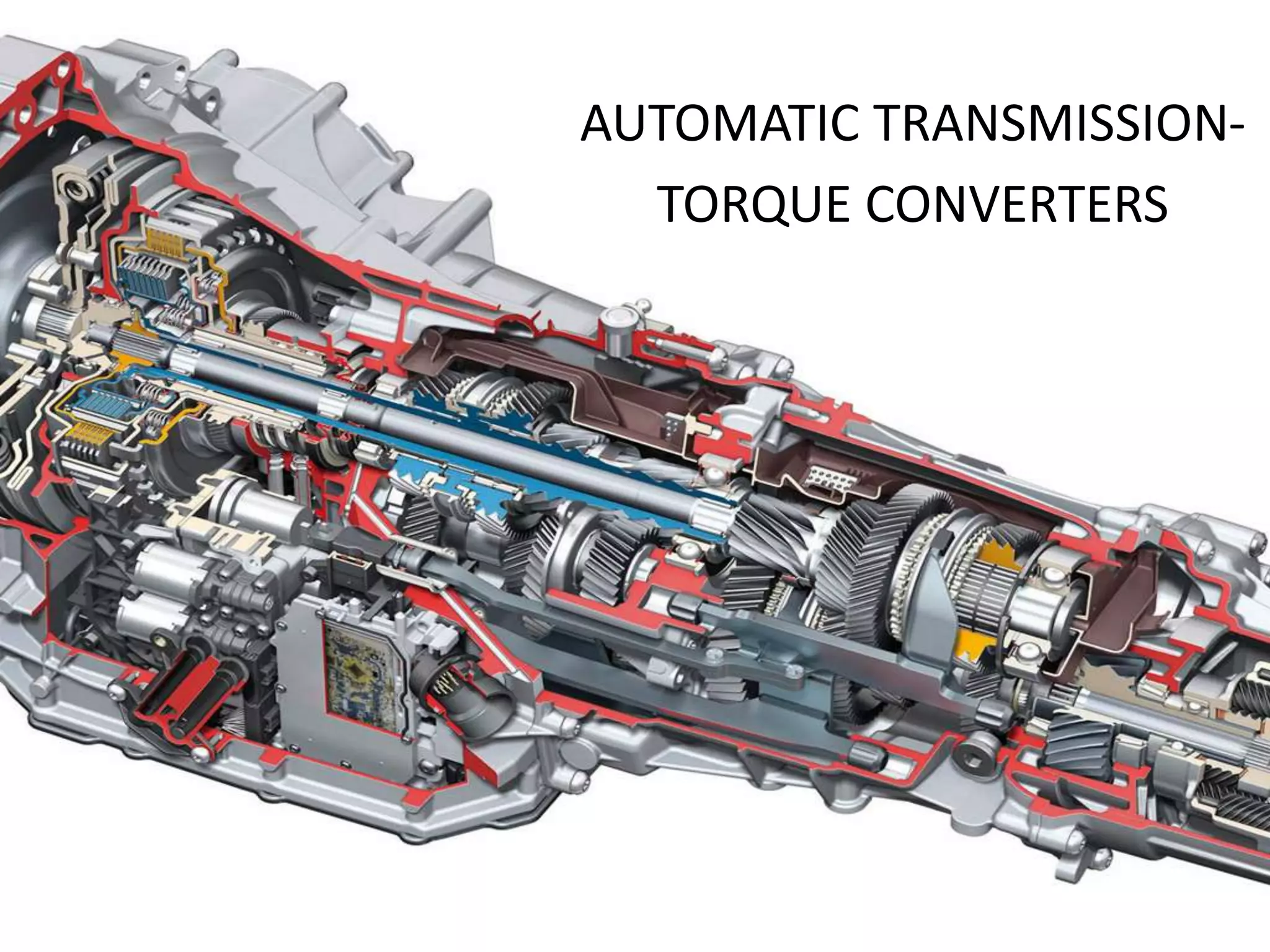

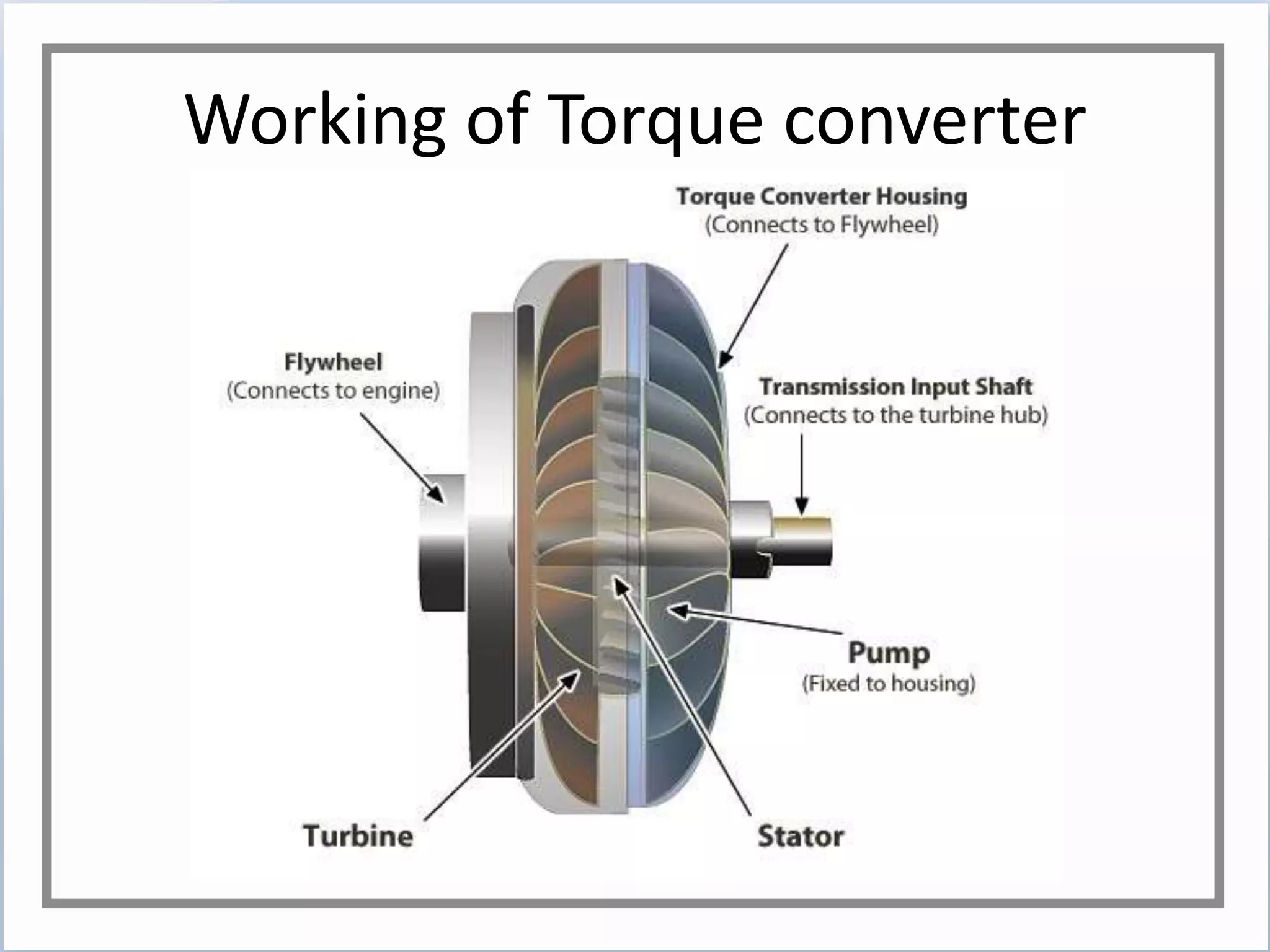

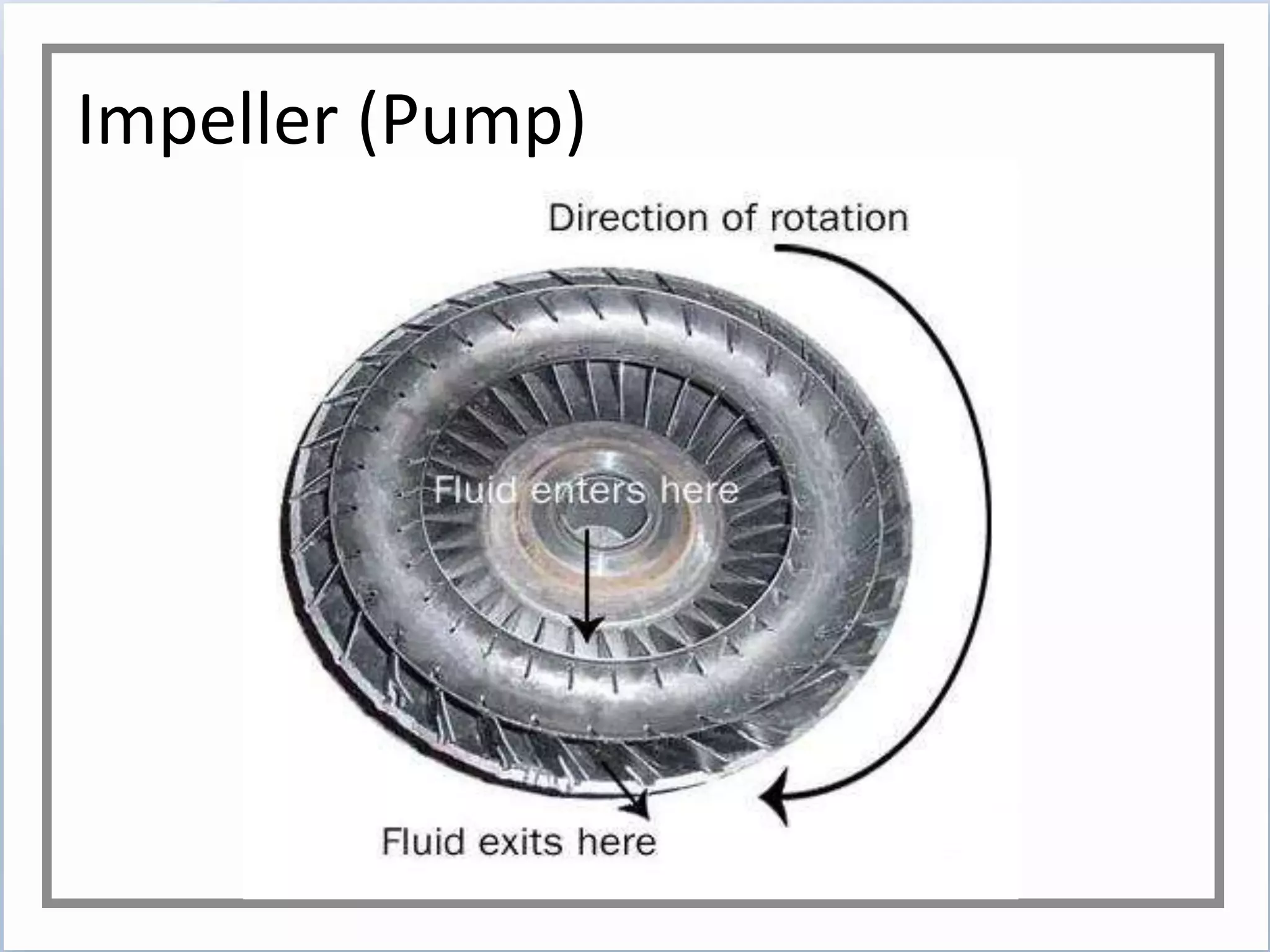

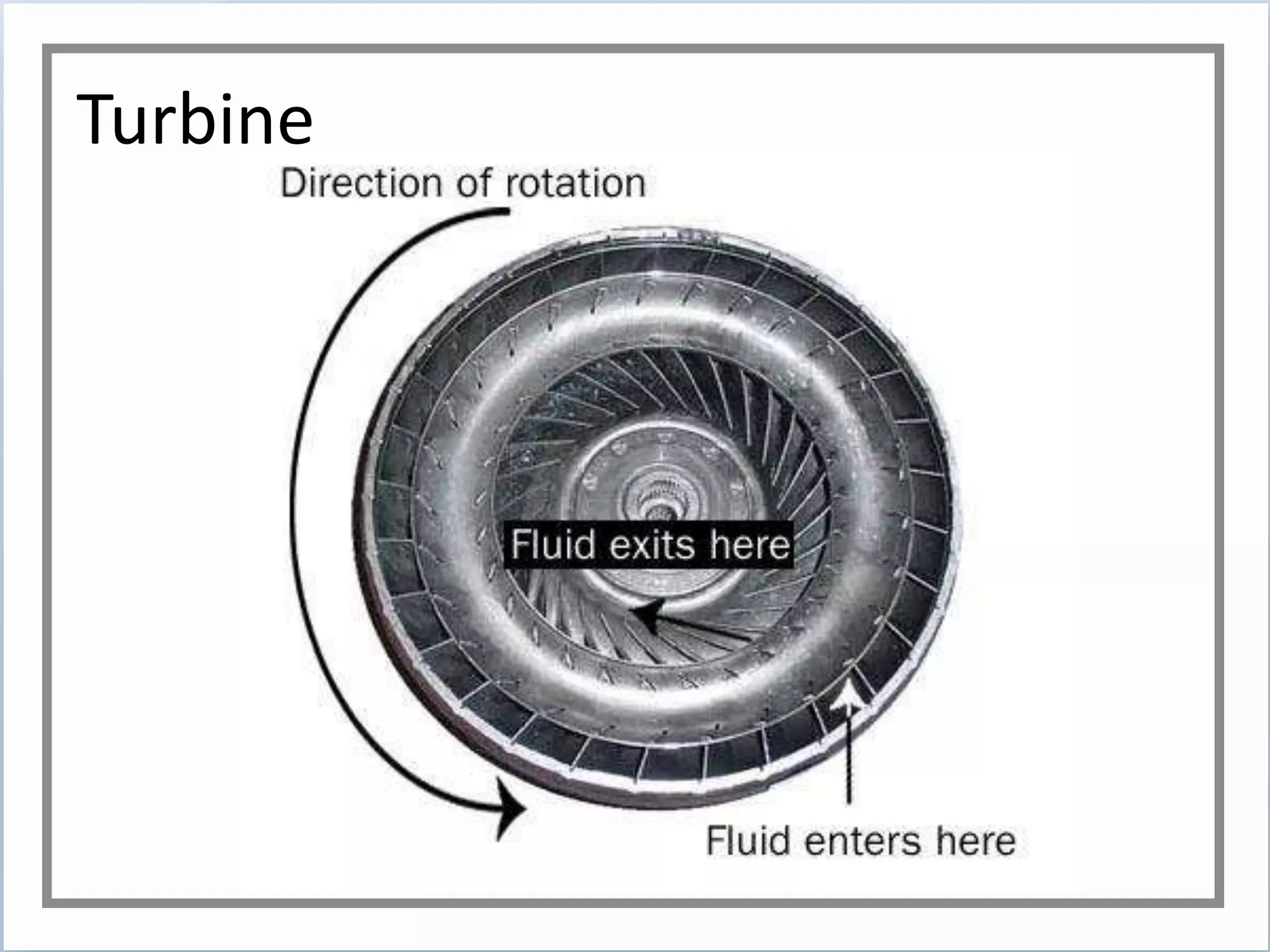

The document discusses various hydraulic systems used in automobiles, including power steering, automatic transmissions, suspension, and braking. It describes how power steering systems use hydraulic pressure to assist steering, noting the main types are integral, rack and pinion, hydro-boost, and linkage. It also explains how a torque converter in an automatic transmission multiplies torque to transfer power from the engine to the transmission. Additionally, it provides details on hydropneumatic suspension and hydrostatic regenerative braking systems.