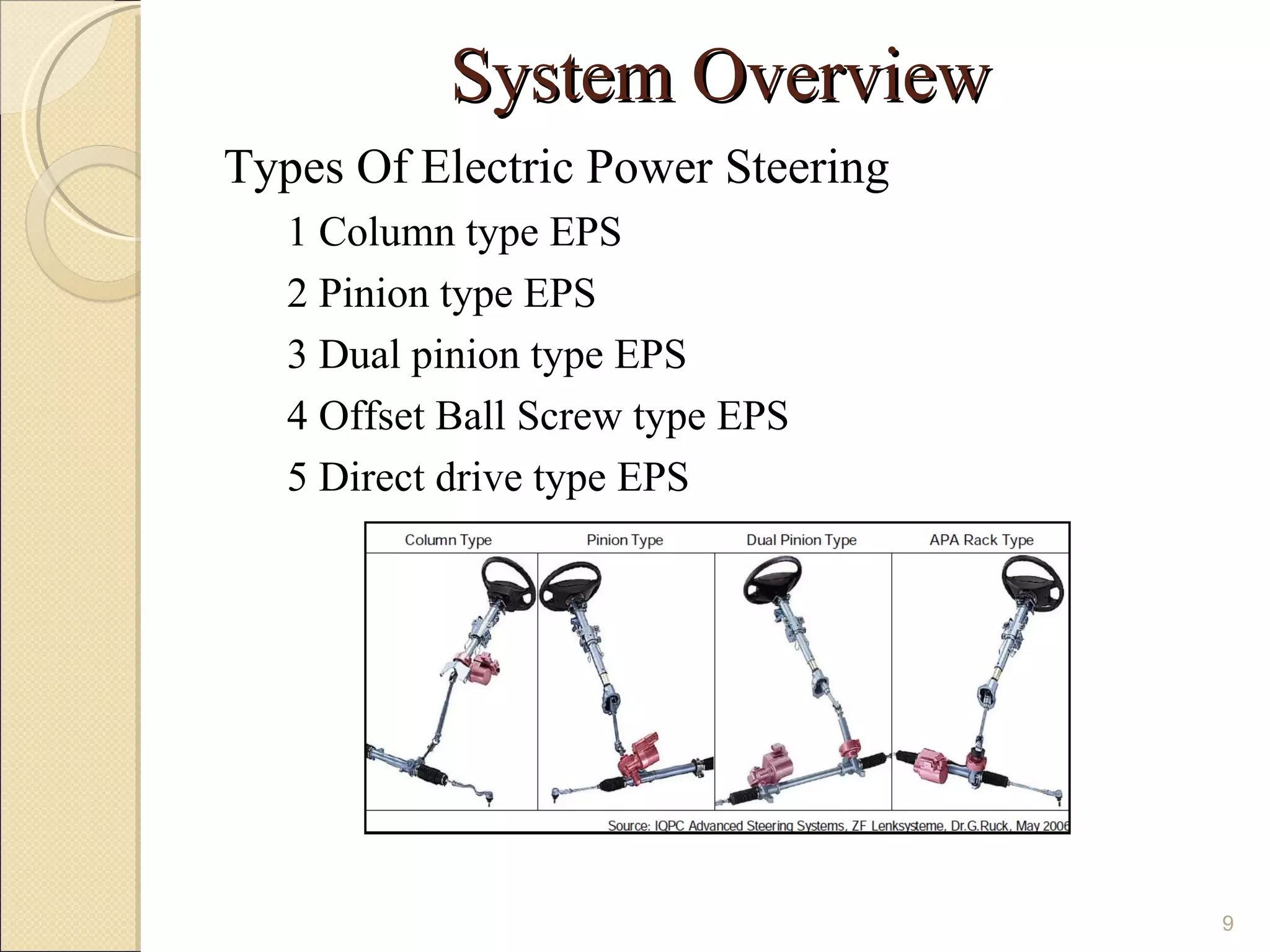

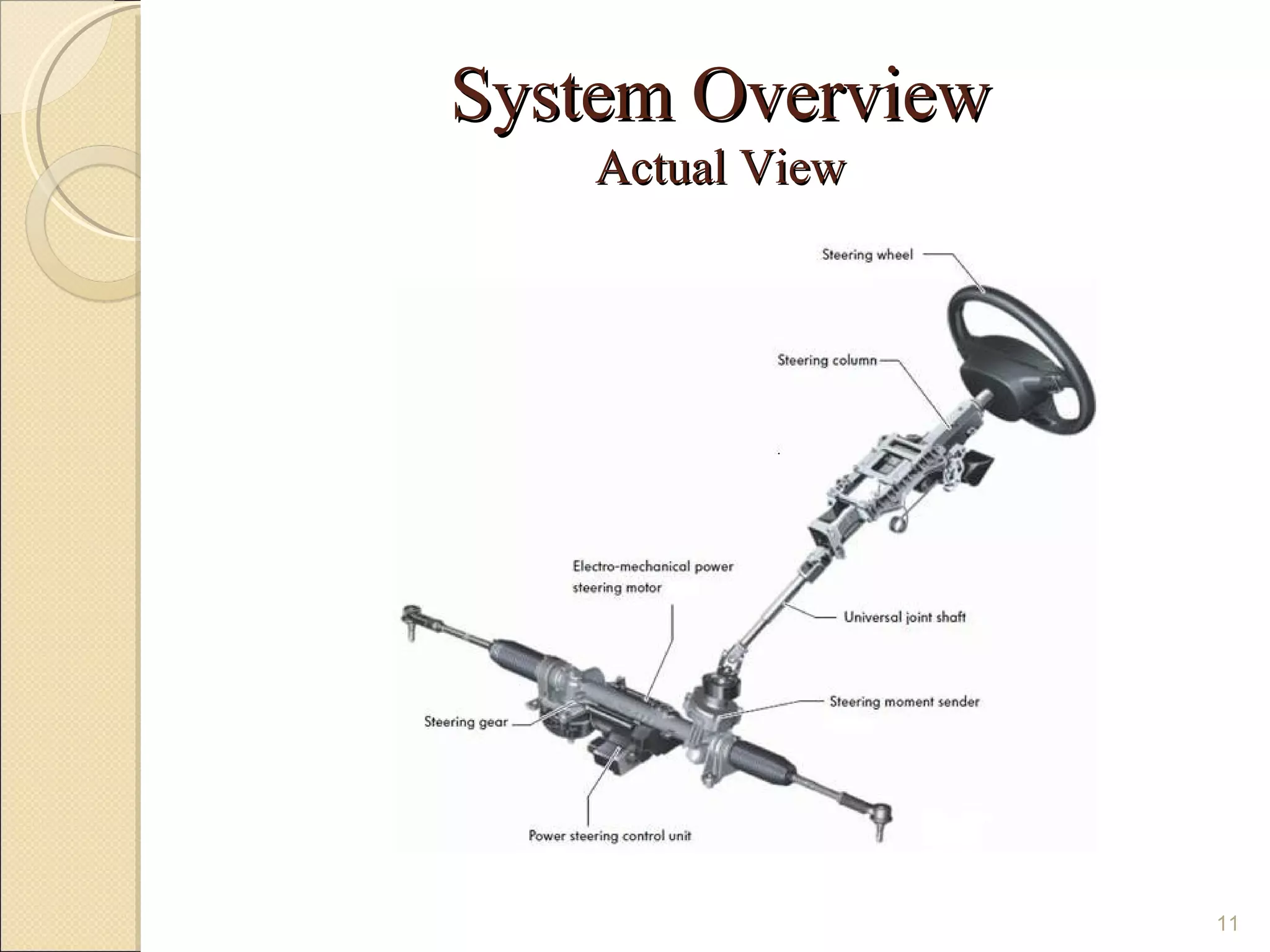

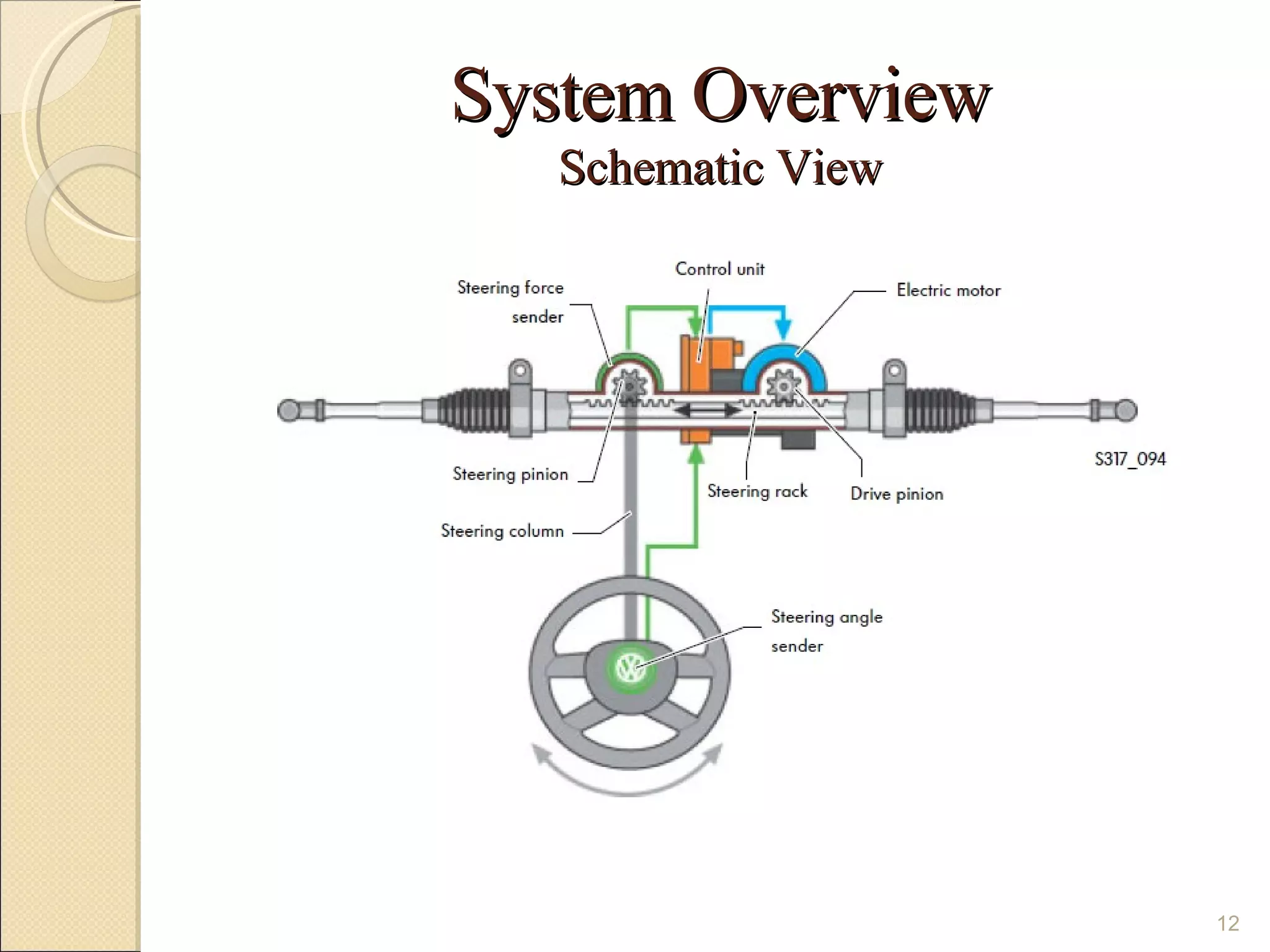

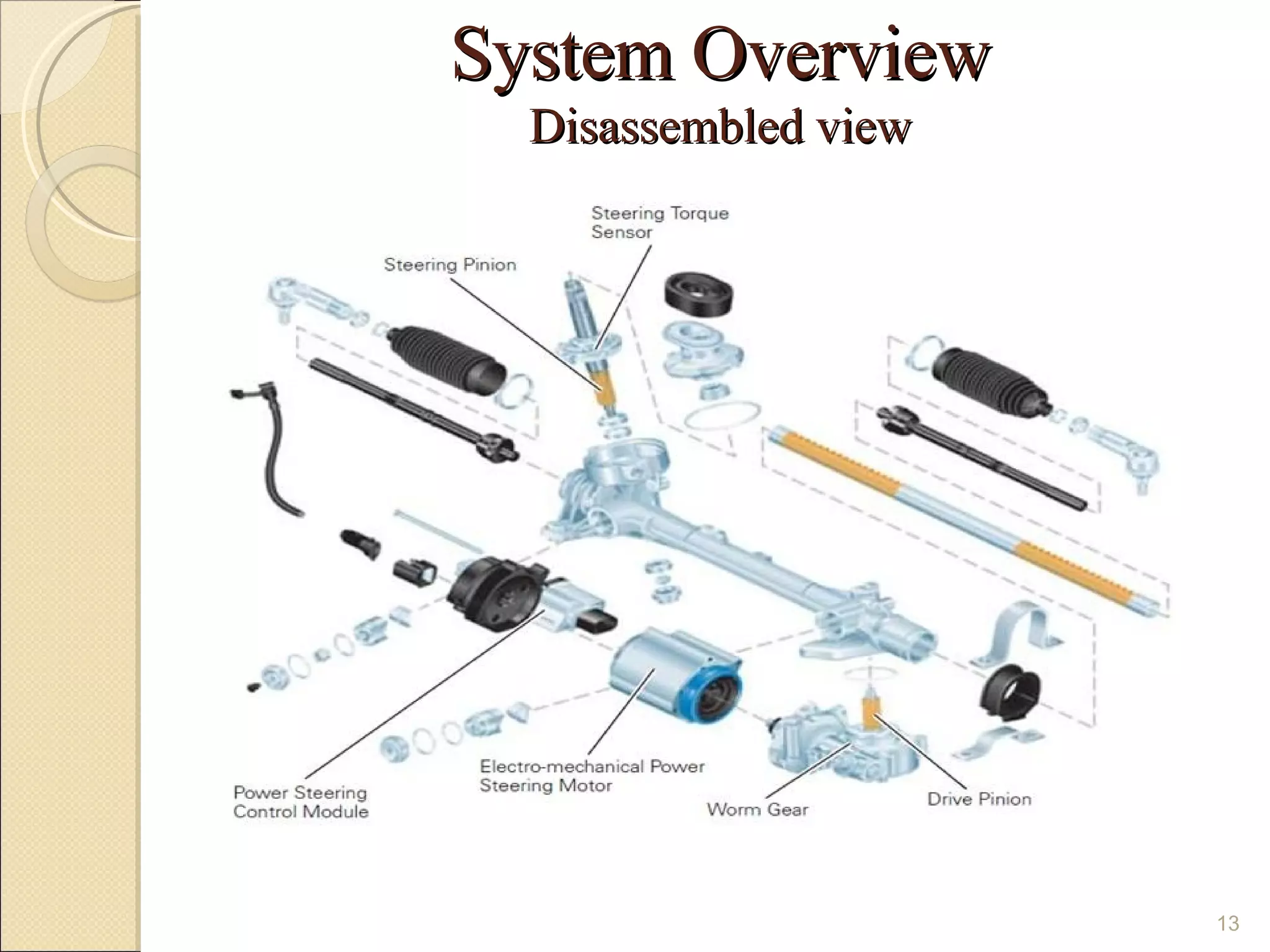

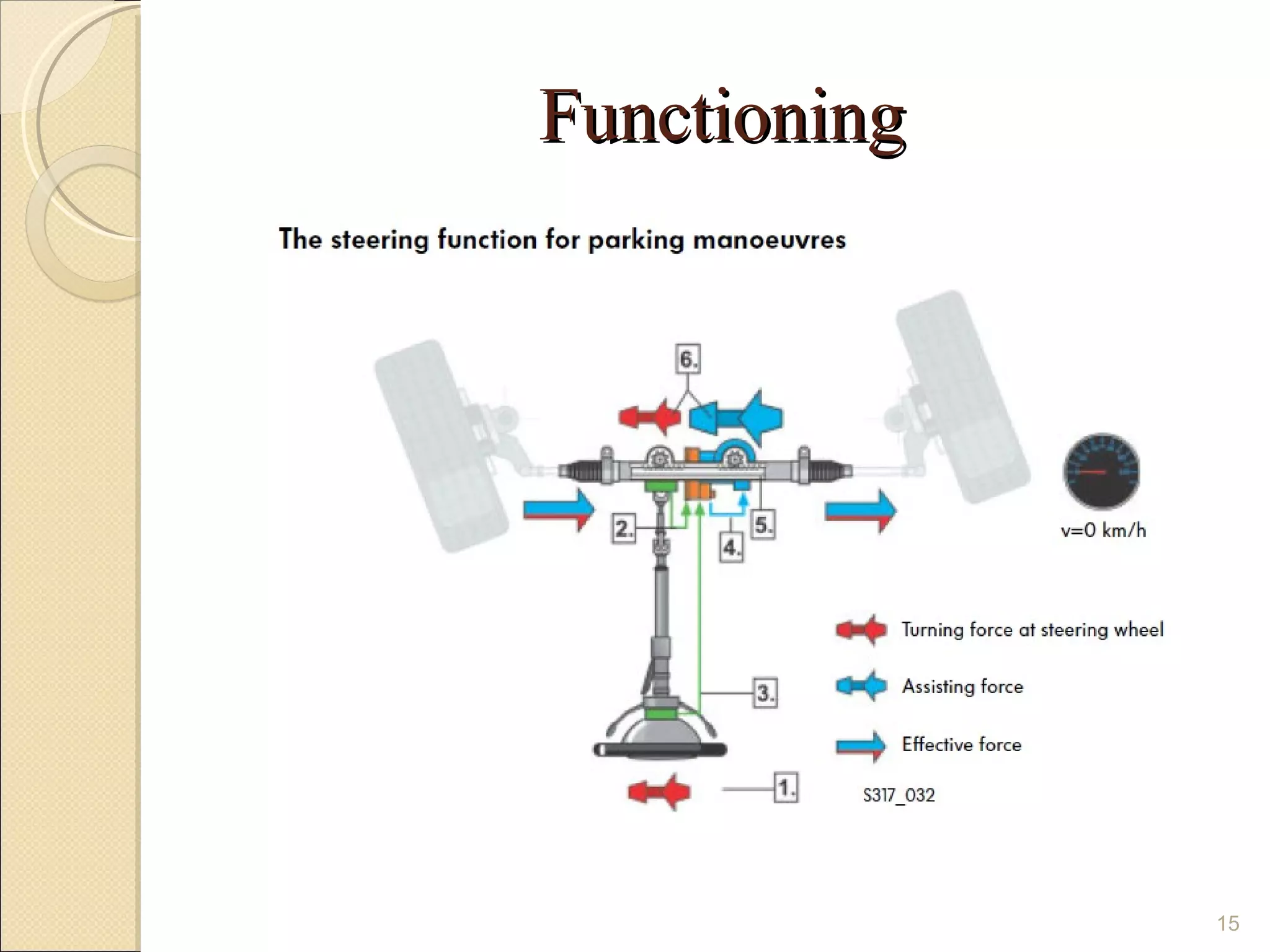

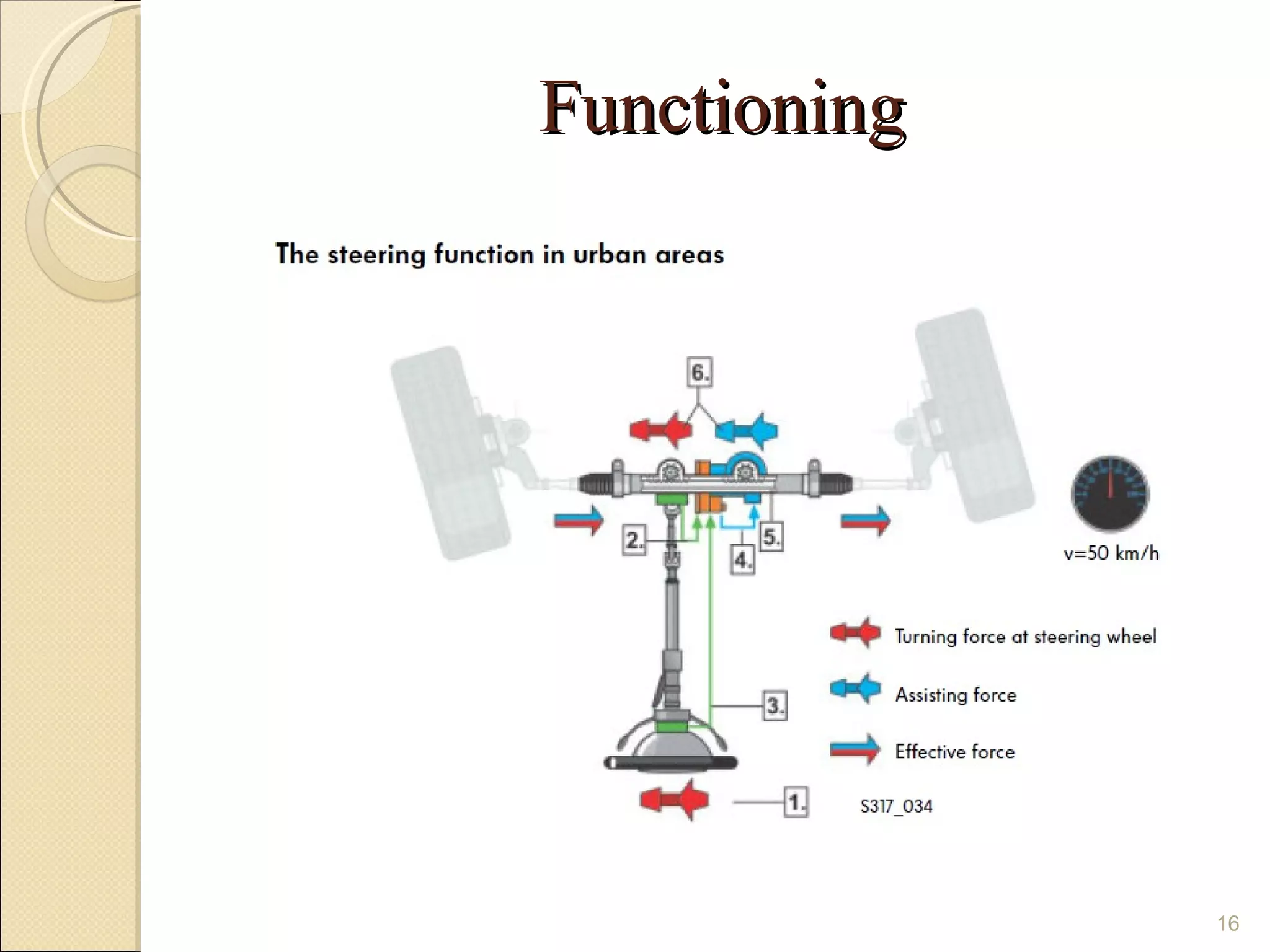

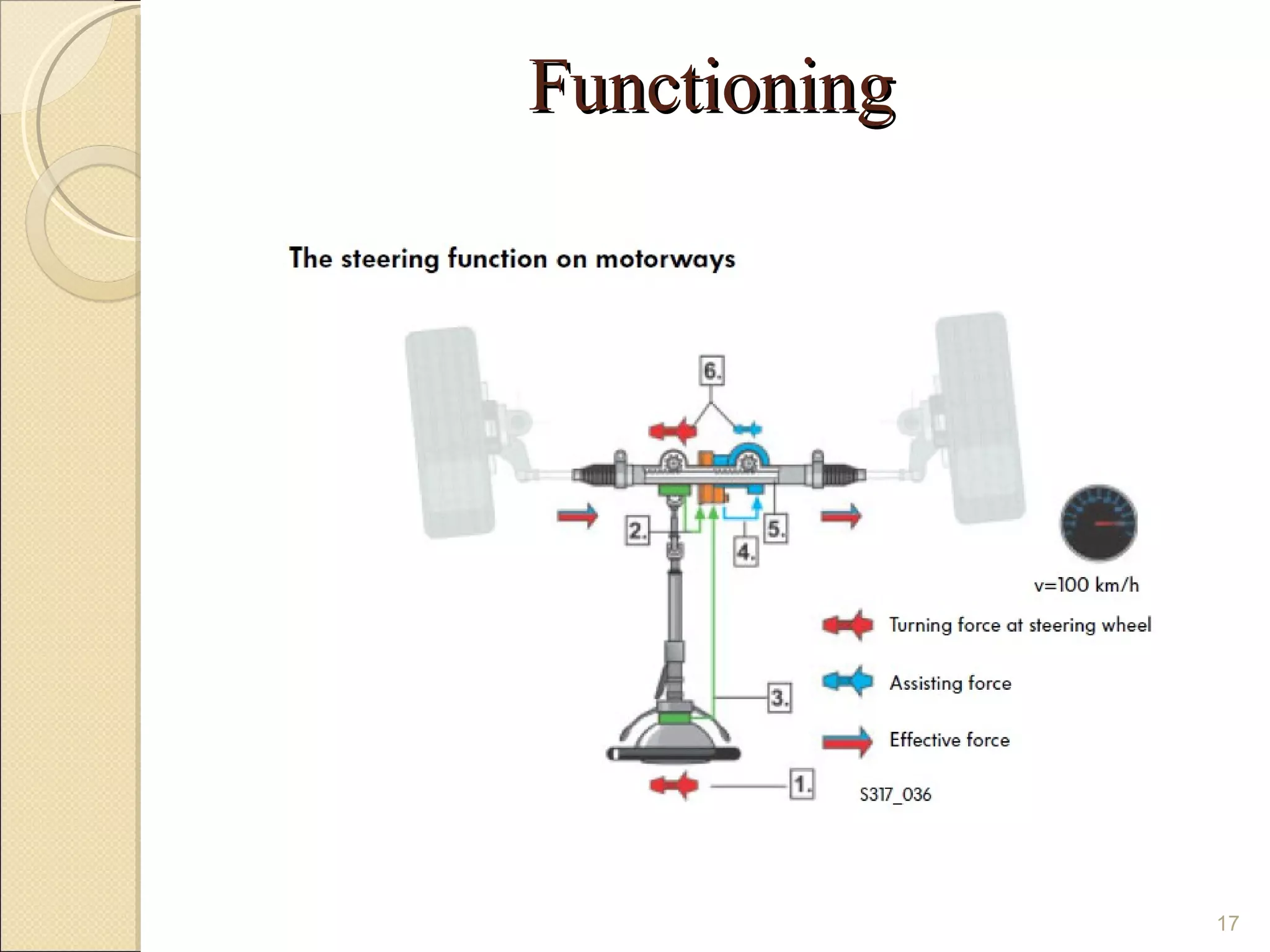

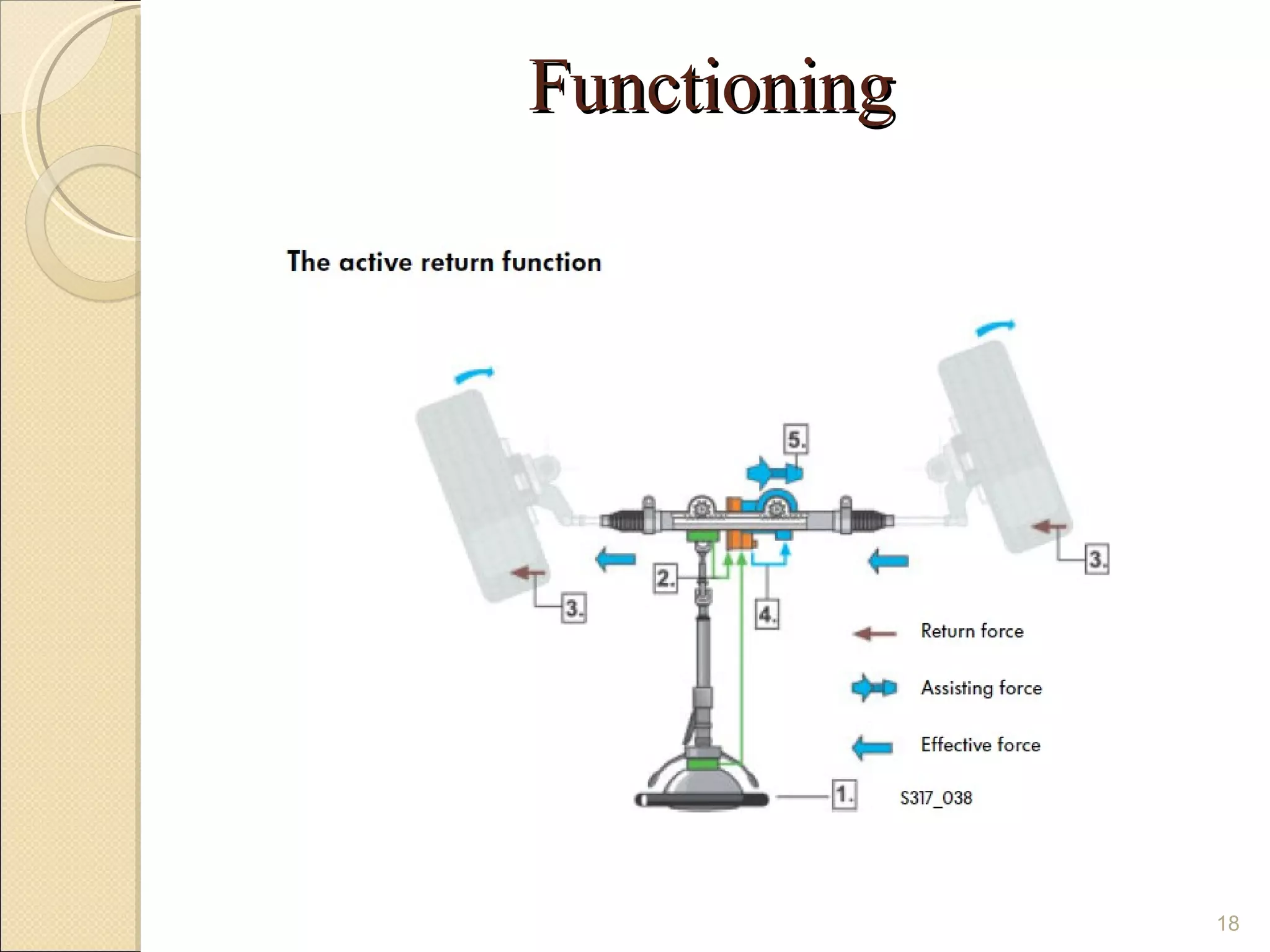

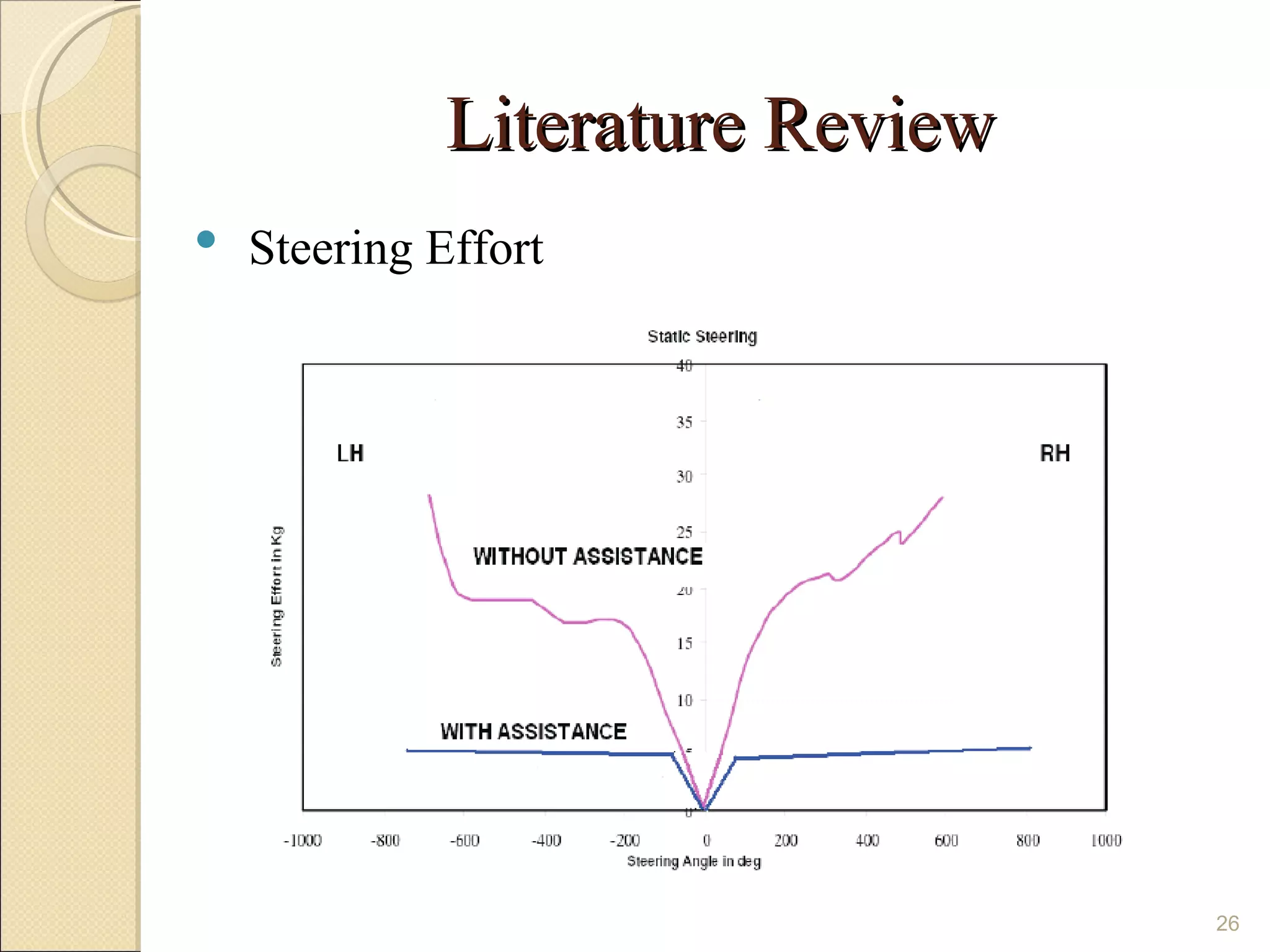

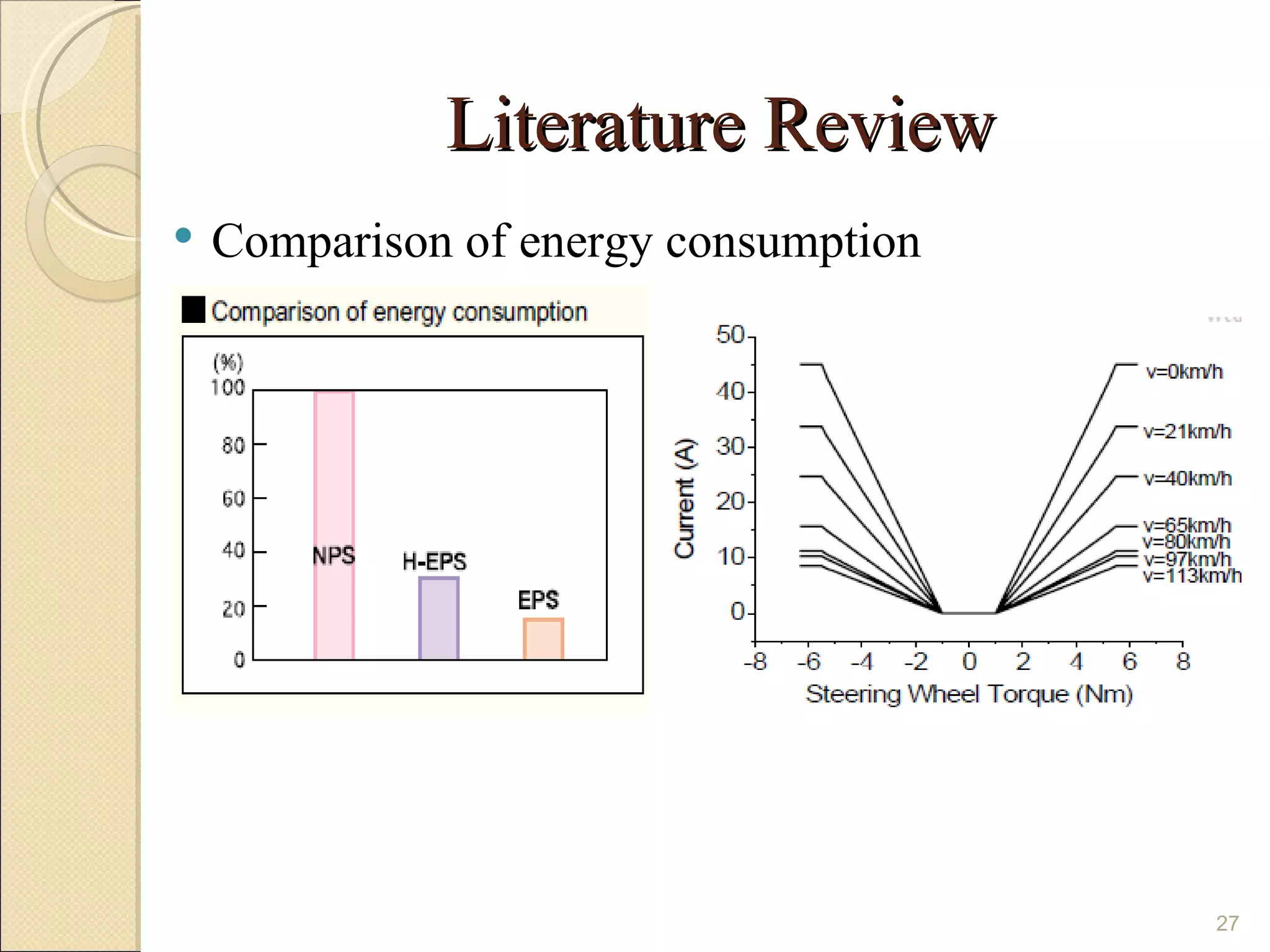

The document discusses advances in electric power steering mechanisms. It provides an overview of electric power steering systems, describing the main components and five modes of operation. It also discusses control strategies for electric power steering that use effort level control based on torque sensing and assistance level control based on vehicle speed. Some benefits of electric power steering over hydraulic power steering systems are also summarized, such as reduced complexity, weight, and fuel consumption.