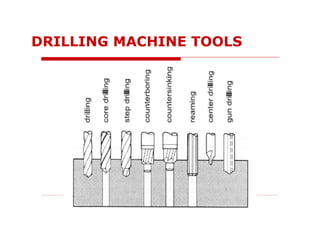

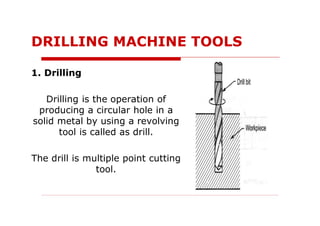

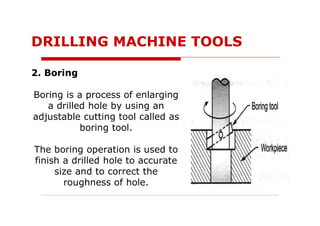

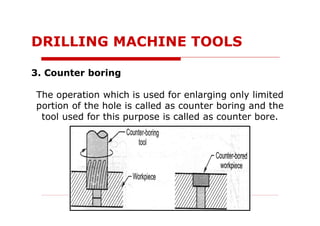

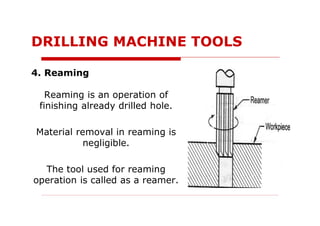

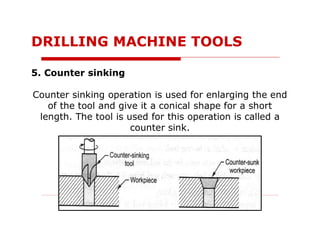

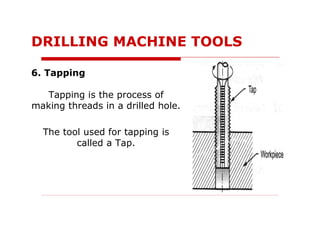

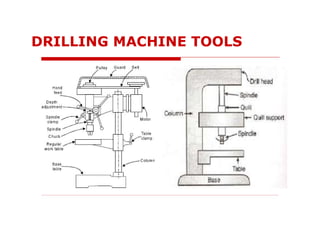

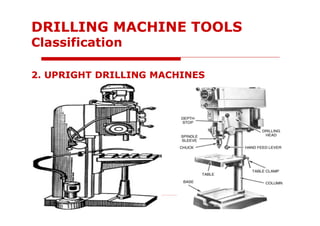

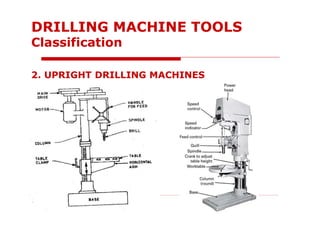

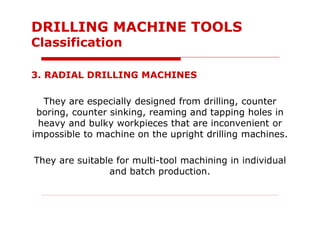

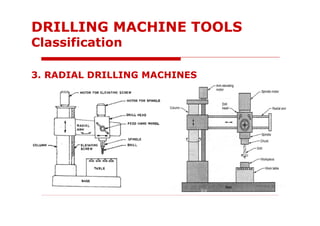

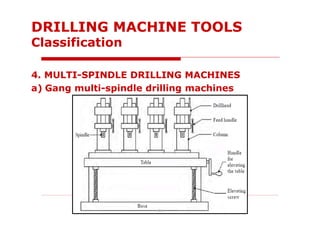

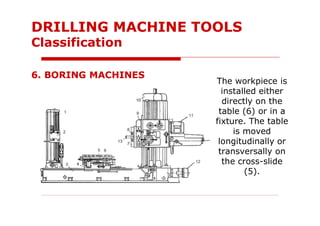

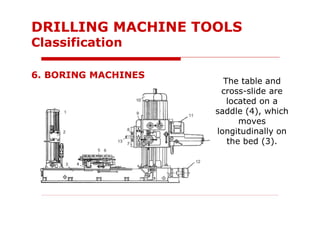

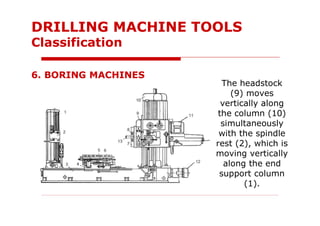

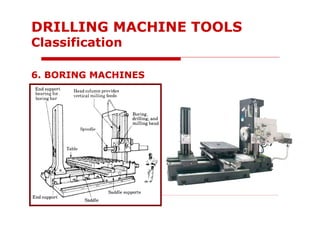

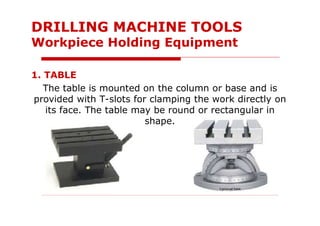

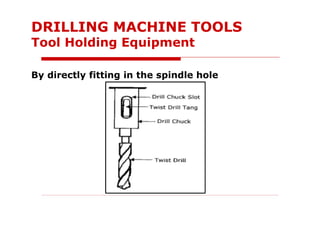

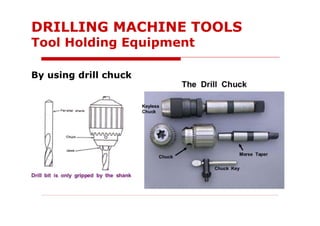

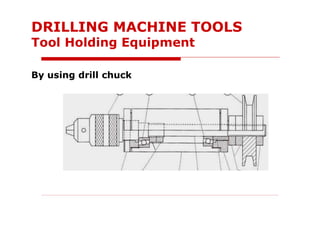

The document provides an overview of drilling machine tools, including their working principles, operations like drilling, boring, reaming, and tapping, as well as various machine types such as bench-type, upright, radial, and multi-spindle drilling machines. It details the important components of drilling machines, like the base, column, spindle, and cutting tools, along with methods for workpiece holding and tool holding. Additionally, it discusses the classification of drilling machines based on their design and functionality for specific machining tasks.