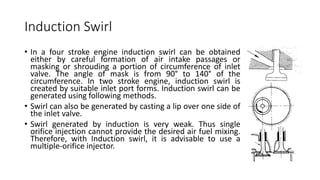

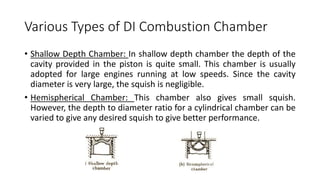

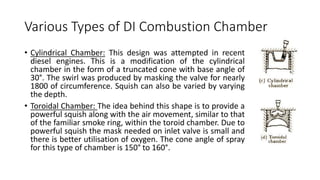

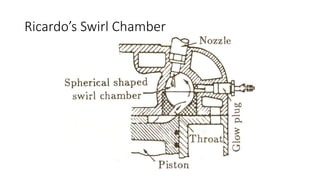

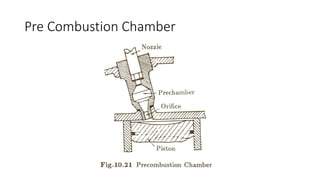

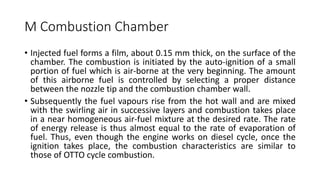

The document discusses various types of combustion chambers used in compression ignition (C.I.) engines, focusing on design considerations such as thermal efficiency, fuel versatility, and emissions. It details several chamber types including direct injection and pre-combustion chambers, highlighting their advantages and disadvantages, such as ease of starting and fuel atomization versus complexity and maintenance issues. Additionally, it reviews specific technologies like induction and compression swirl, and the M-combustion chamber, noting their impact on engine performance and fuel efficiency.