This document discusses tool signatures and different tool geometry systems. It provides information on:

1) The objective is to explain tool signatures, how tool angles affect machining, and why understanding signatures is important.

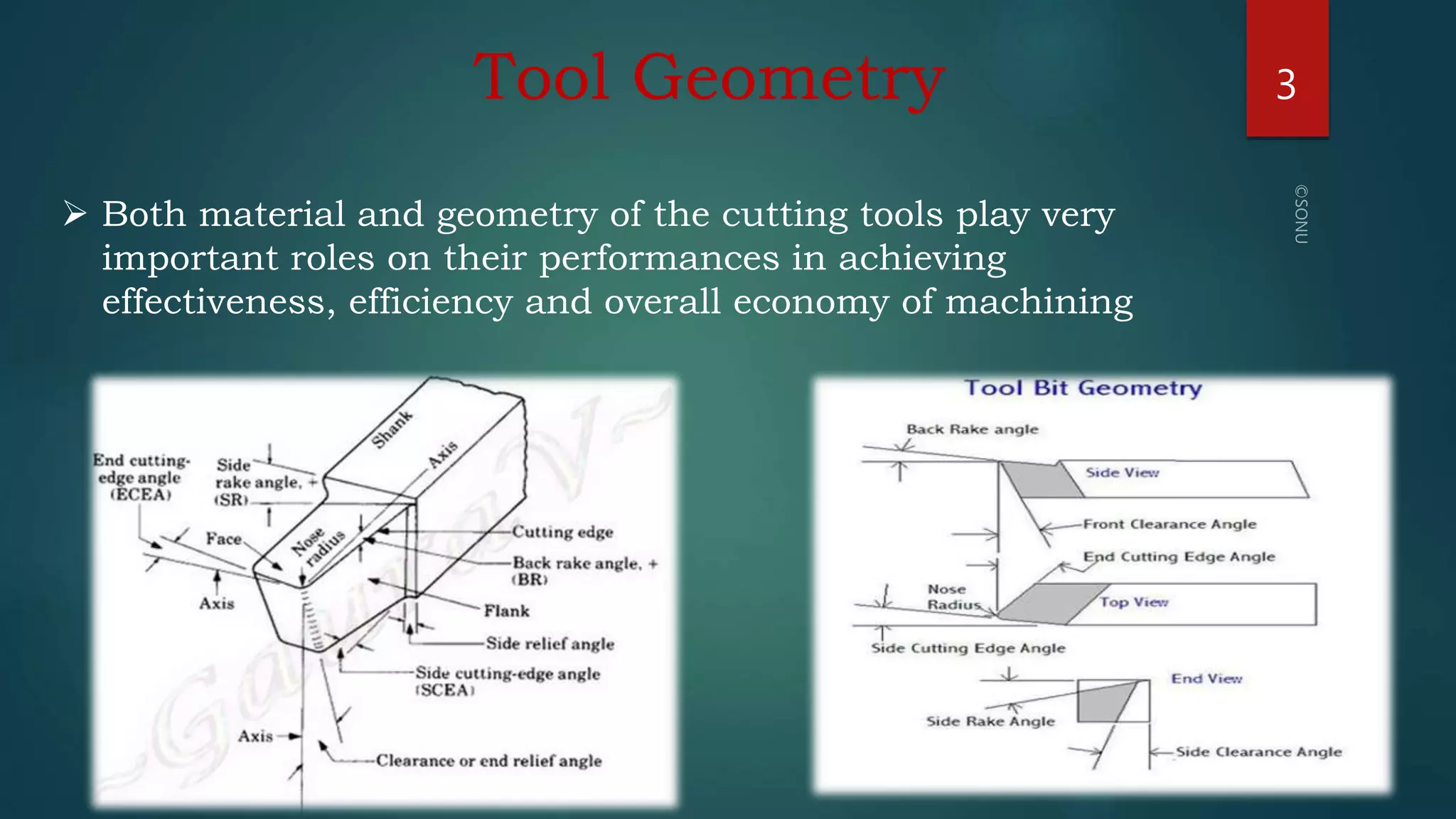

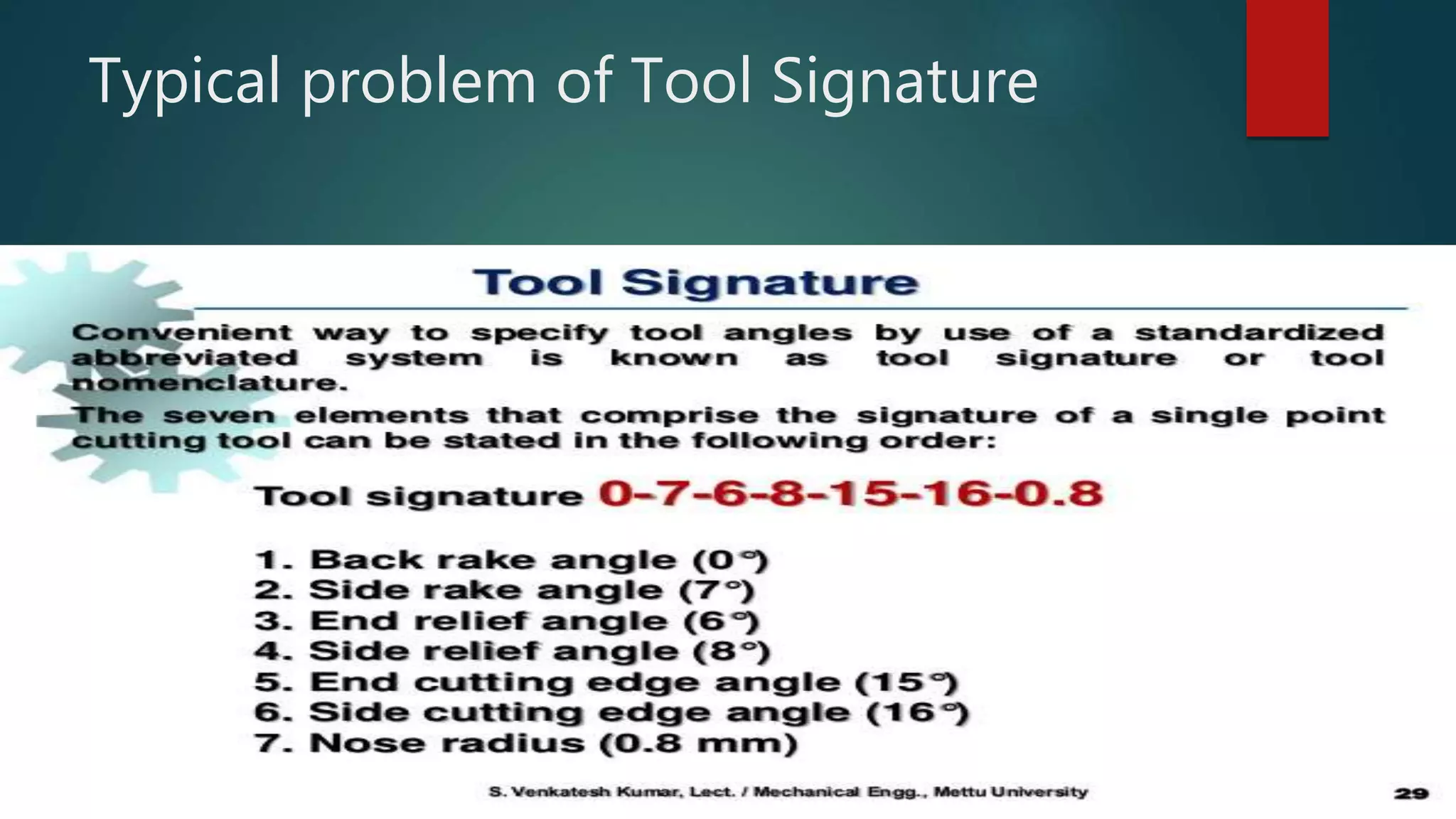

2) Tool signatures specify the key angles of a cutting tool in a standardized way. They indicate the active angles during cutting.

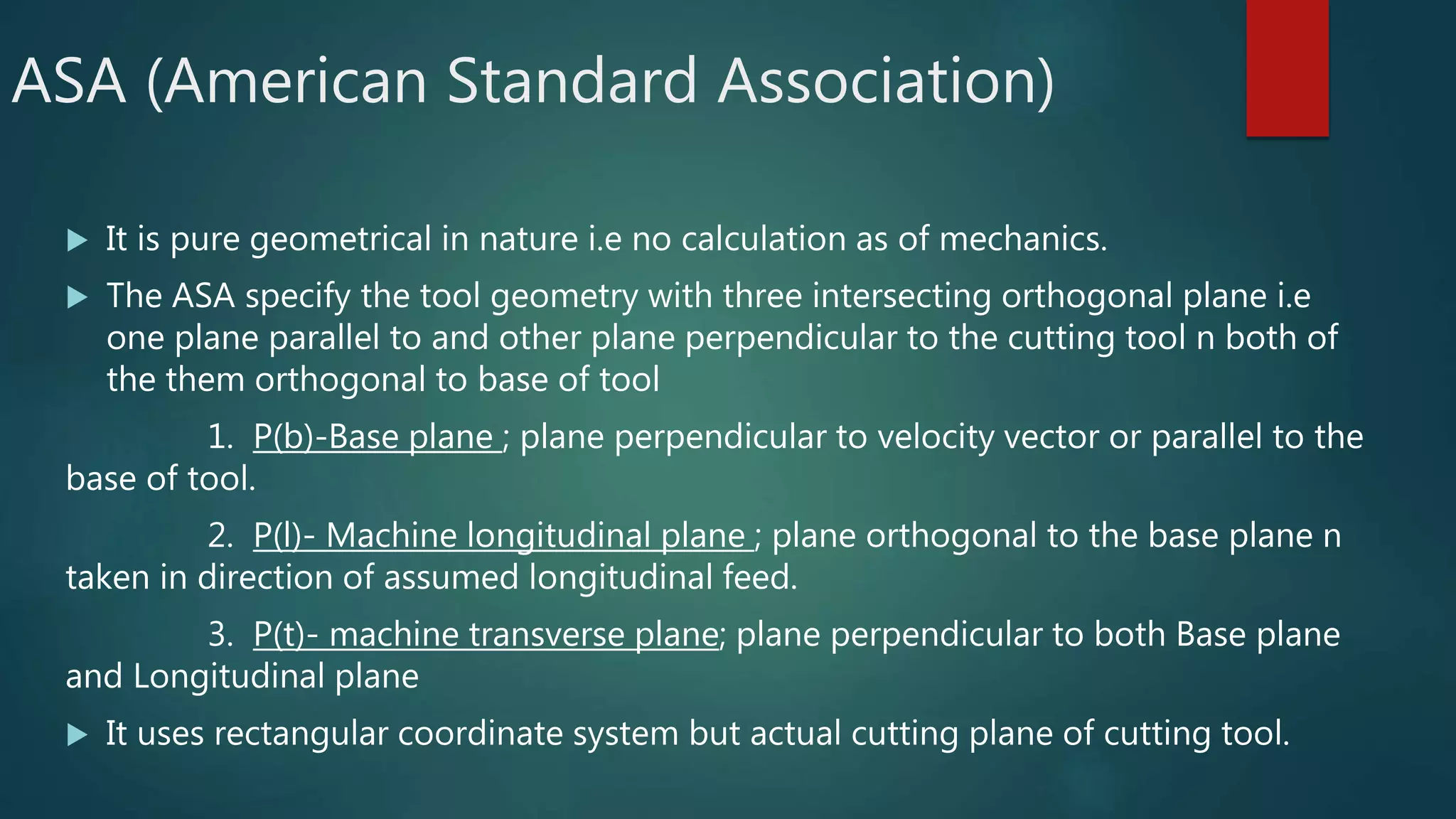

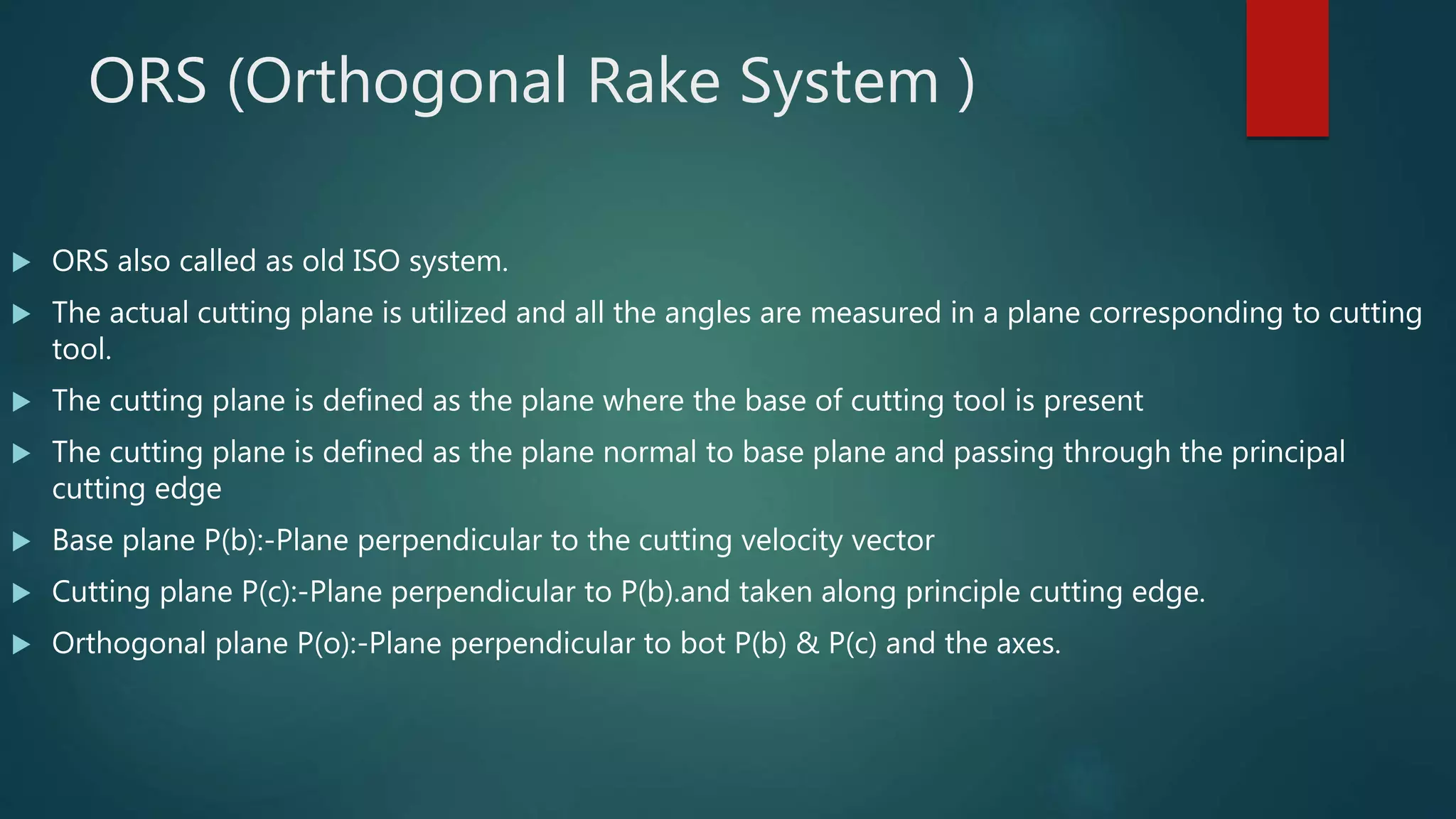

3) Three common tool geometry systems are described - ASA, ORS, and NRS. They each define tool angles differently based on different reference planes.