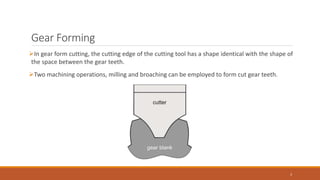

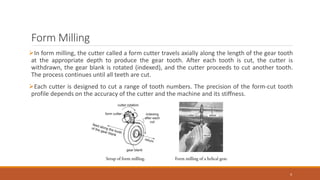

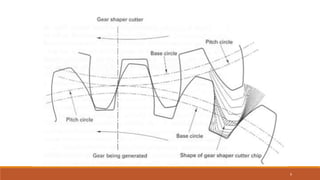

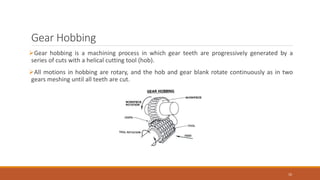

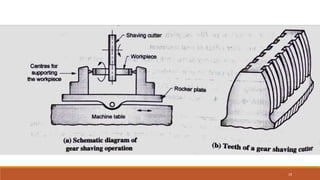

The document outlines various gear manufacturing methods, including casting, forging, machining, and finishing techniques such as gear hobbing and shaping. Key processes discussed include gear forming and generating, highlighting form milling, broaching, and grinding as essential for achieving precise gear teeth profiles. Additionally, the importance of finishing operations like gear shaving and grinding is emphasized to ensure optimal performance and longevity of gears.