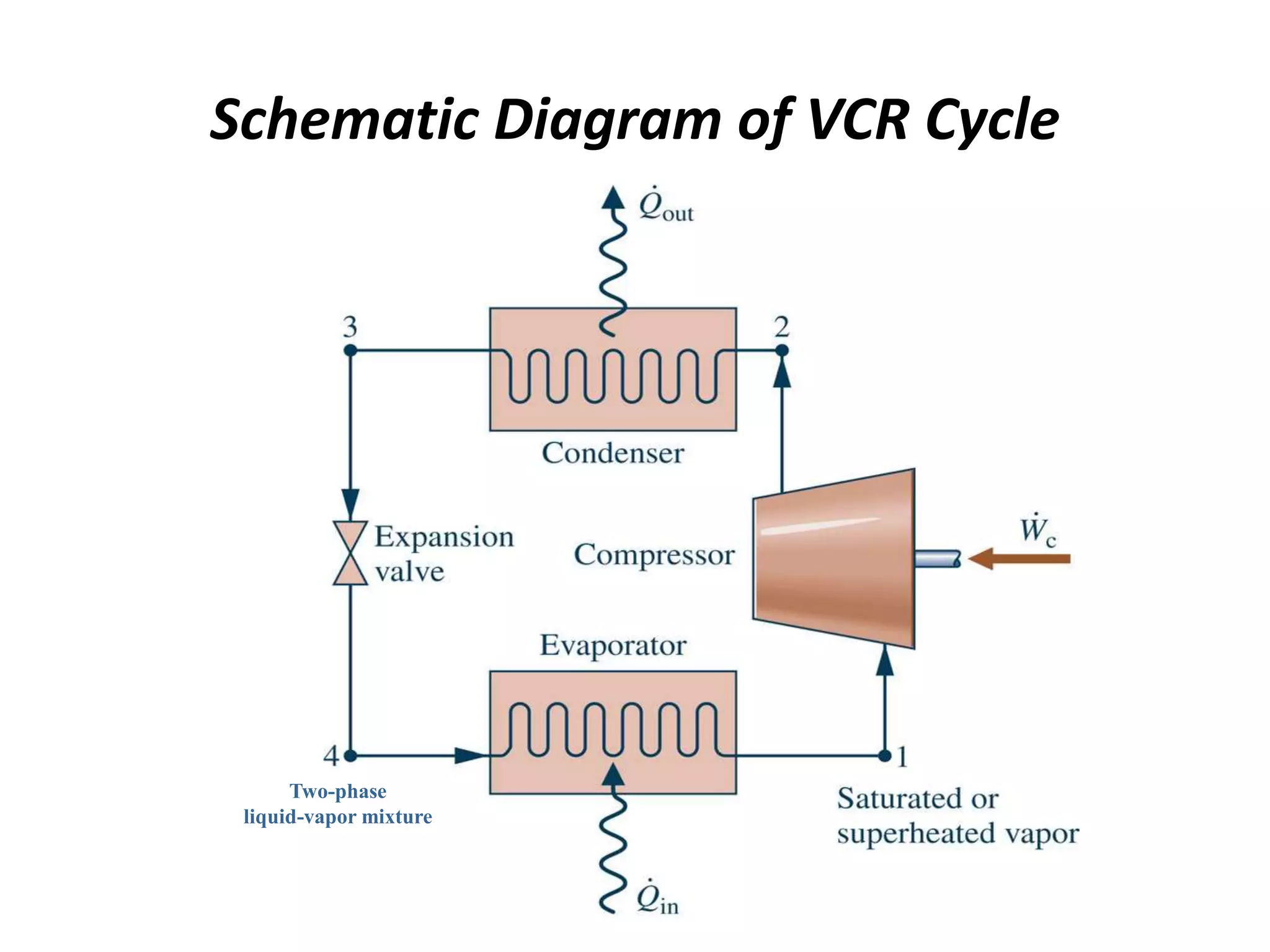

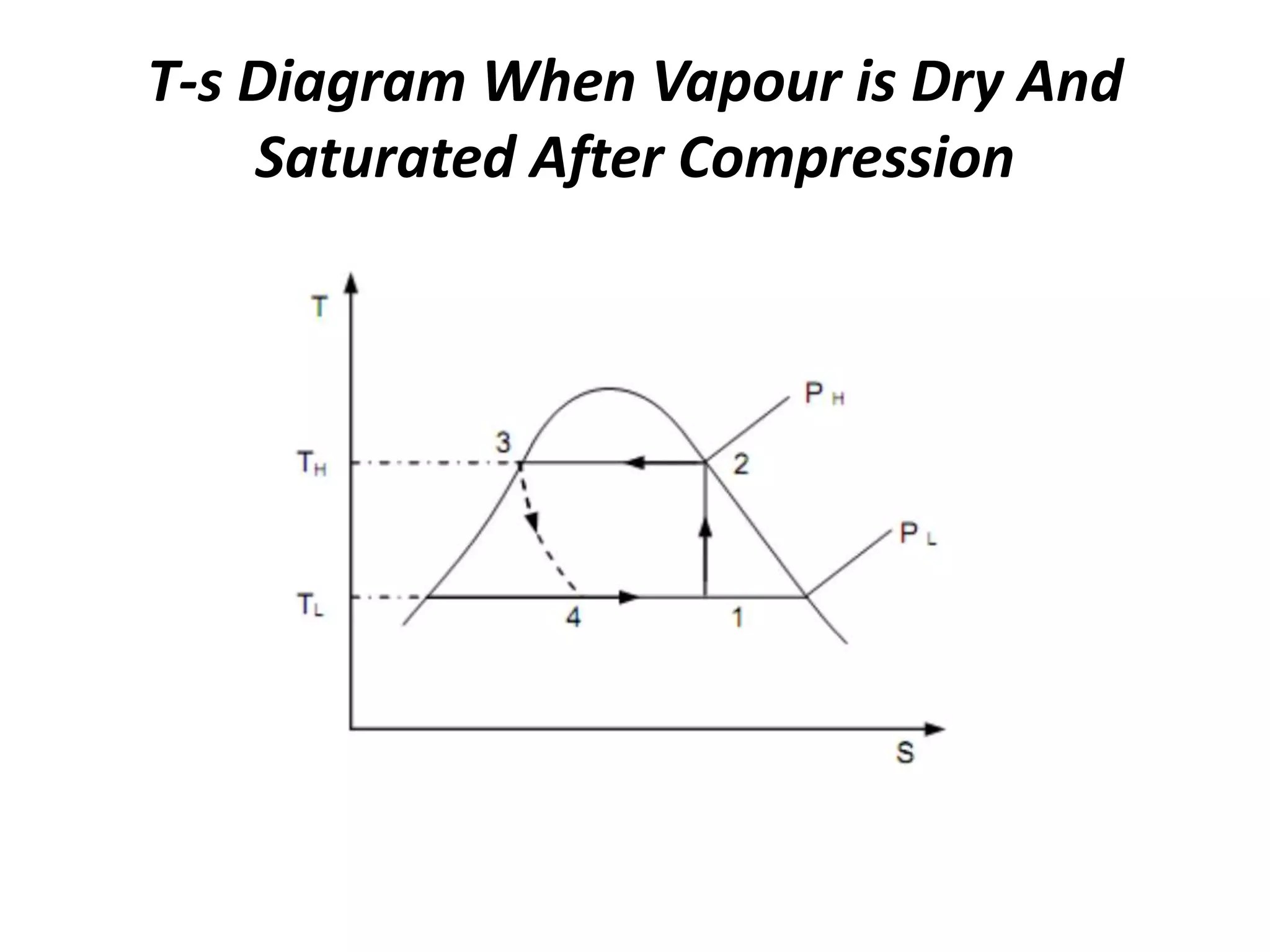

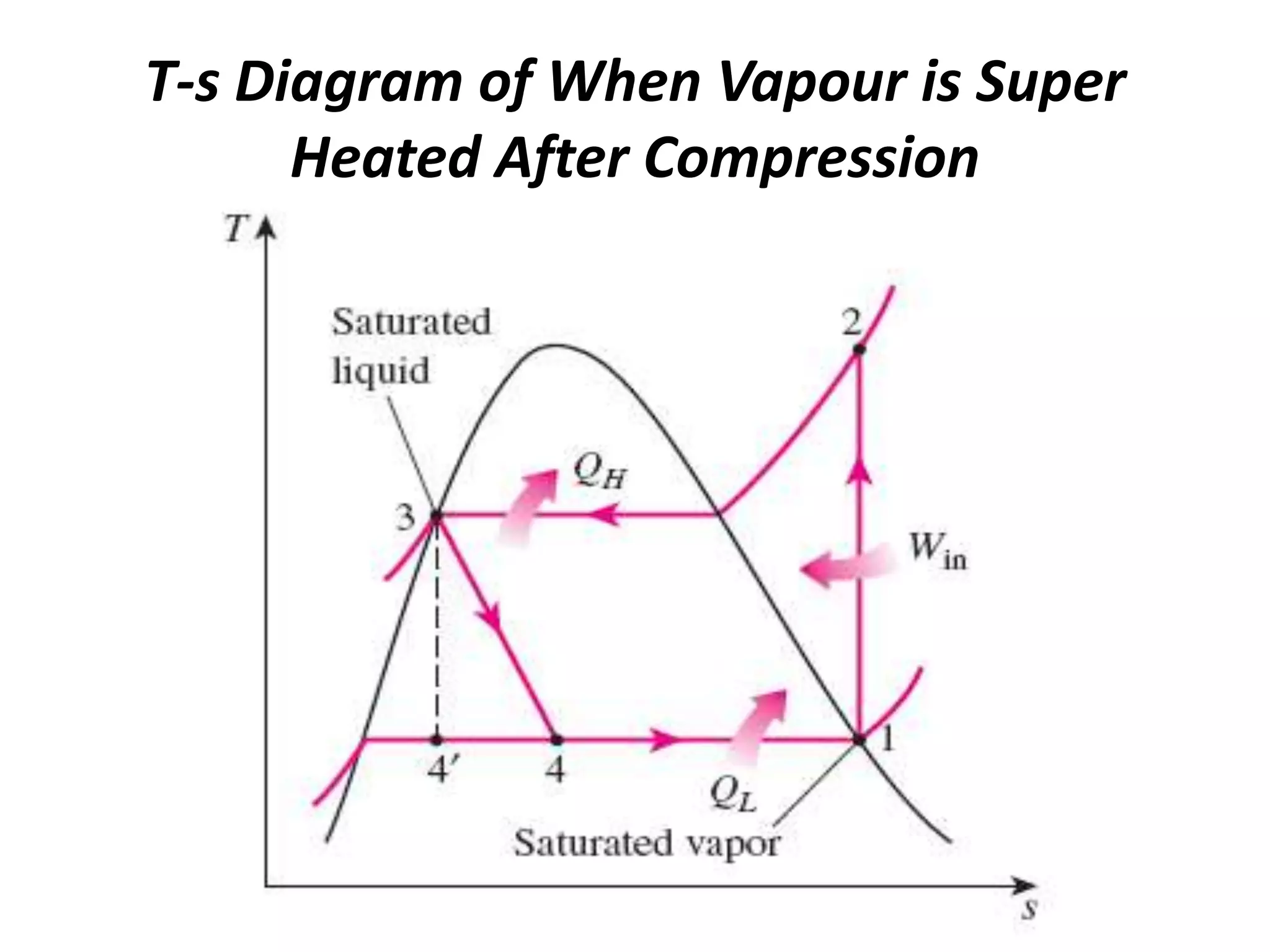

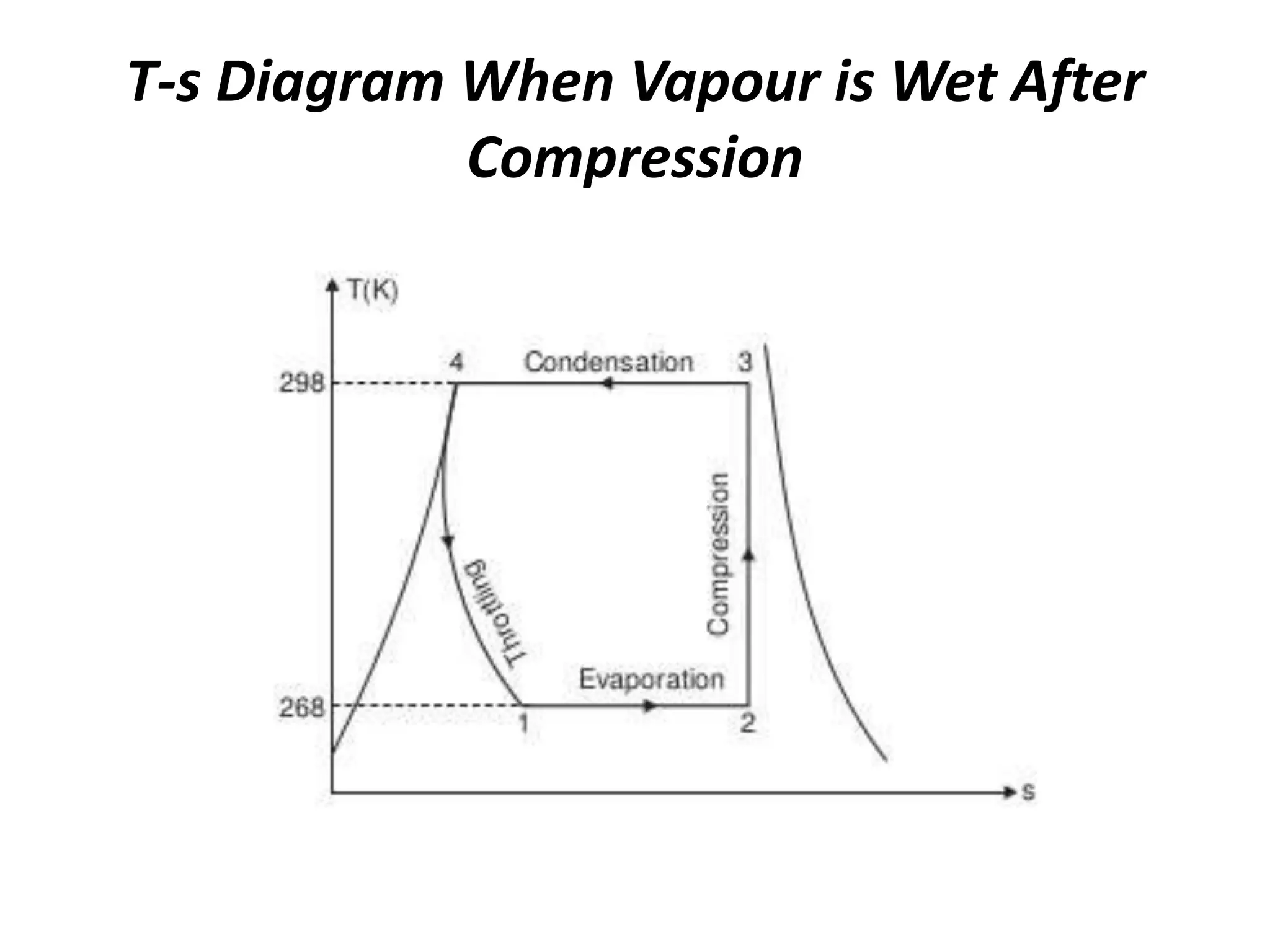

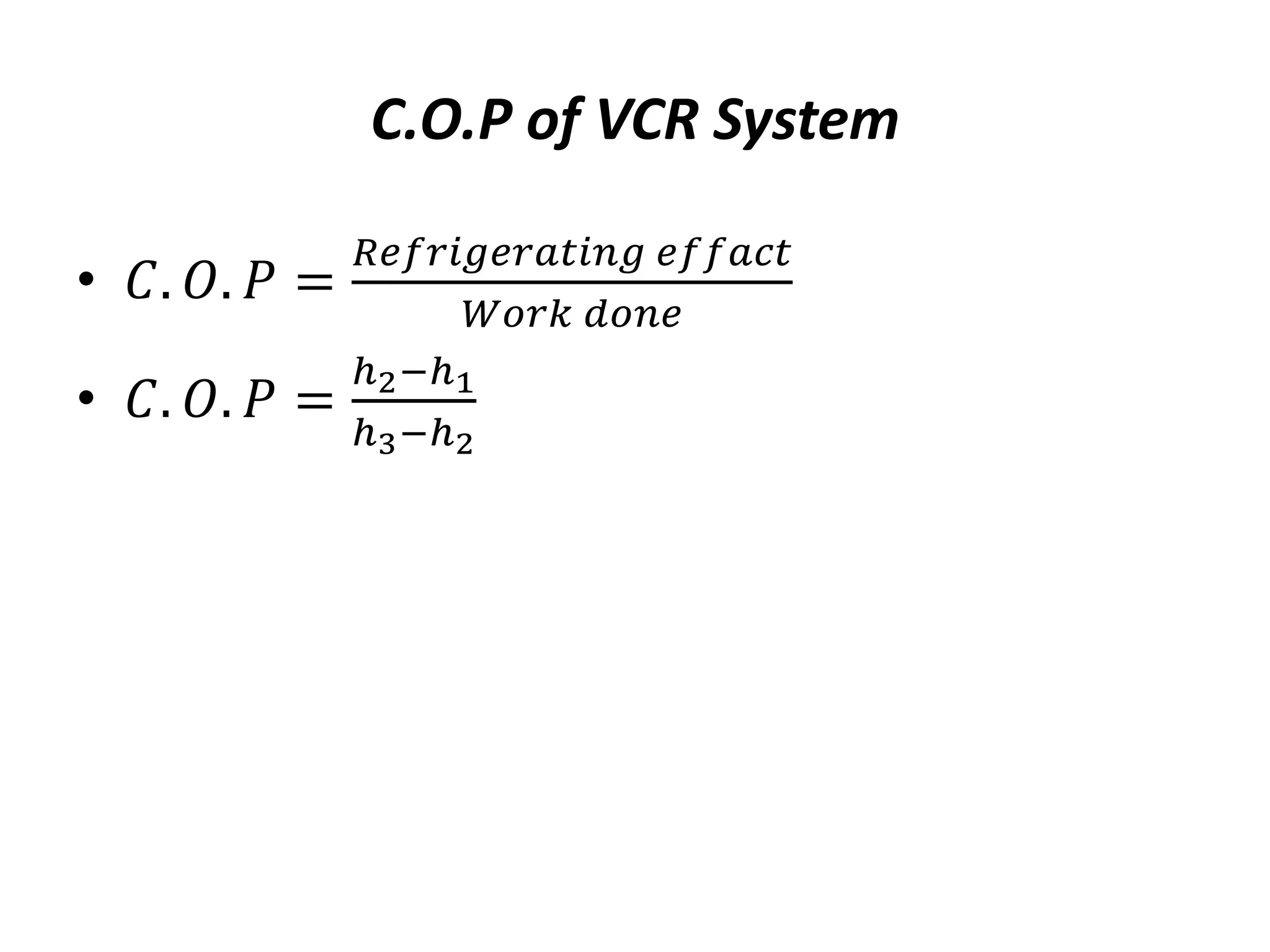

The simple vapour compression cycle is a highly utilized refrigeration system for both domestic and industrial applications, employing a refrigerant that condenses and evaporates near atmospheric conditions. It offers advantages such as smaller size, lower running costs, and high coefficient of performance, but has drawbacks including high initial costs and leakage prevention challenges. The system consists of four main components: evaporator, compressor, condenser, and expansion valve, and involves specific processes for refrigerant evaporation, compression, condensation, and expansion.