1) Dielectric fluids used in EDM must provide an oxygen-free environment for machining, have strong dielectric resistance to prevent electrical breakdown, and ionize during sparking. Common dielectric fluids are kerosene and deionized water.

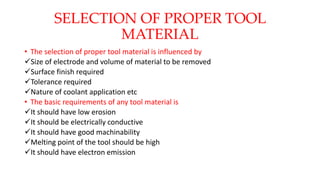

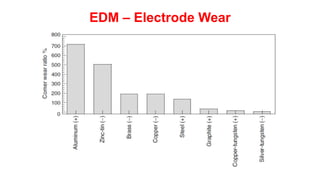

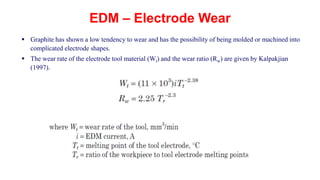

2) Electrode materials for EDM tools must have high electrical and thermal conductivity for efficient sparking and less tool wear, and high melting points to prevent material removal from the tool. Common materials are graphite, copper, and brass.

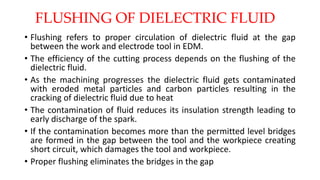

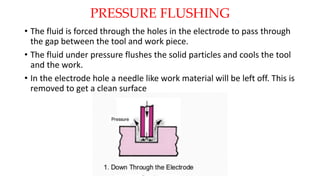

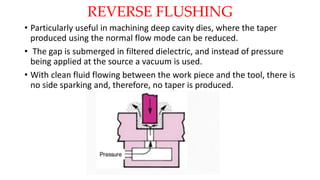

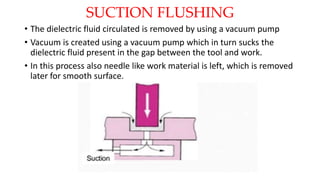

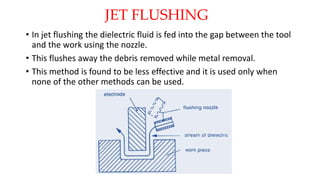

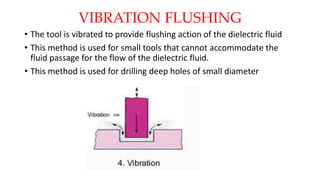

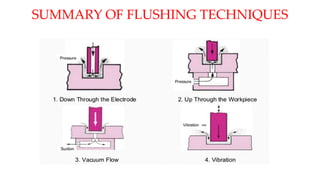

3) Proper flushing of dielectric fluid is important to remove debris from the spark gap and prevent short-circuiting, improving surface finish and material removal rate. Common flushing techniques are pressure, reverse, suction, jet