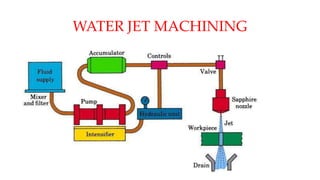

Water jet machining uses high-pressure water to cut soft, non-metallic materials. It works by converting the kinetic energy of the water jet into pressure energy when it strikes the material, inducing stresses that exceed the material's shear strength and loosening small chips. The water jet machining system consists of a pump to pressurize water, which is then accelerated through a nozzle to cut the material. It allows clean, precise cutting without thermal damage and is suitable for cutting intricate contours in materials like paper, plastics, wood and rubber.