The document outlines the Compex course for training personnel to work safely on electrical apparatus in hazardous environments, detailing both theoretical knowledge and practical assessments conducted in simulated conditions. The training focuses on competence validation testing and covers standards, installation, inspection, and maintenance procedures. It emphasizes the critical need for skilled training to ensure safety in environments with flammable materials.

![March 2010 ©

4

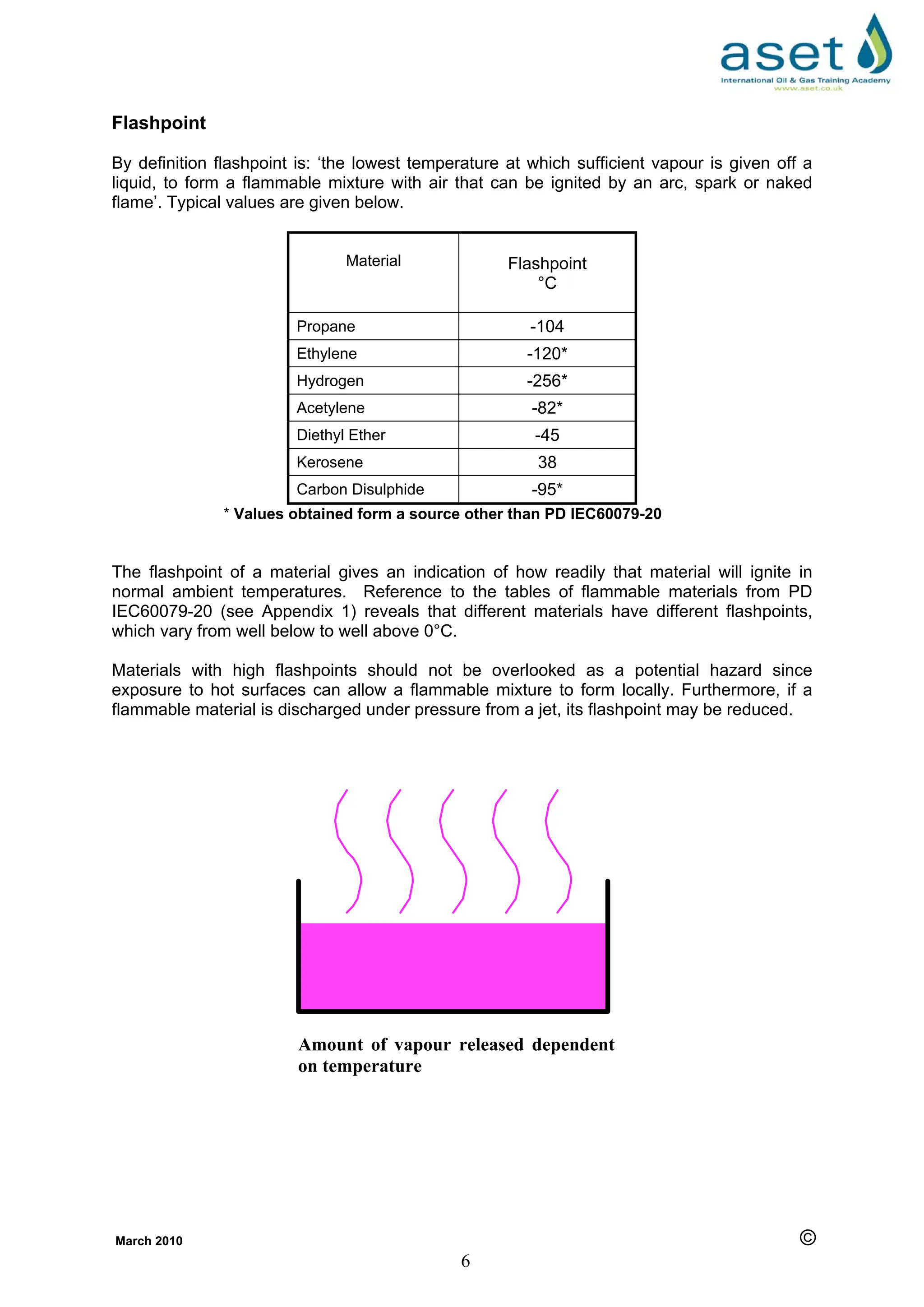

Definition

BS EN60079-11 defines an intrinsically safe circuit as:

‘A type of protection based on the restriction of electrical energy within apparatus and of

interconnecting wiring exposed to the potentially explosive atmosphere to a level below that

which can cause ignition by either sparking or heating effects.’

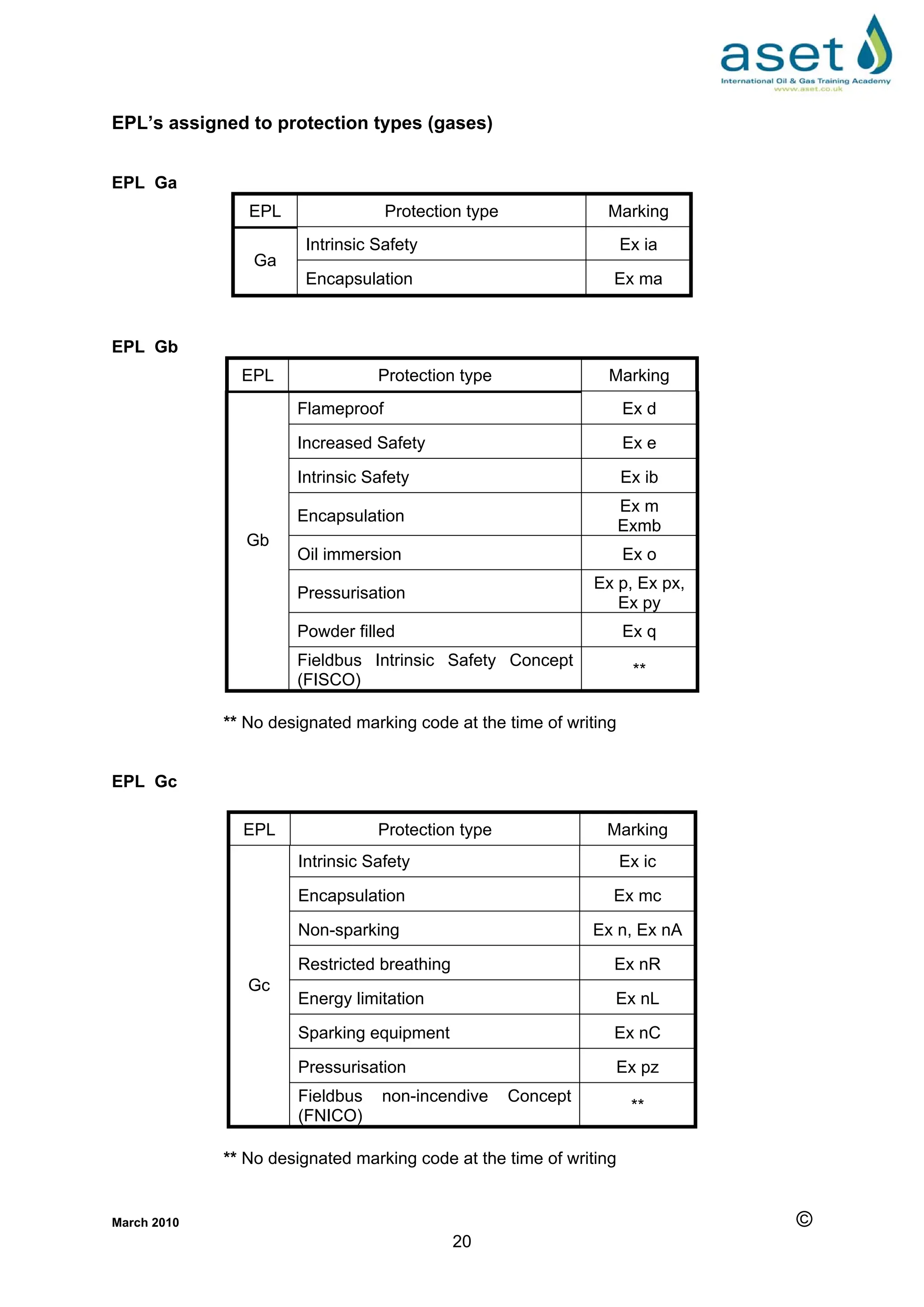

EPL’s: ia - Ga

Ib - Gb

Ic - Gc

Zones of use: 0, 1 & 2 (Ex ia) ( based on traditional approach )

1 & 2 (Ex ib)

2 (Ex ic)

Basic Principles of IS

Intrinsically Safe circuits achieve safety by maintaining very low energy levels such that hot

surfaces will not be produced, and electrical sparks, if they occur, will have insufficient

energy to ignite the most easily ignitable concentration of a flammable mixture. This is

achieved by limiting the voltage and current supplied to the apparatus in the hazardous area.

To maintain safety, it is of paramount importance that these levels of voltage and current are

not exceeded under normal, or even fault conditions.

The circuit parameters, i.e. voltage, current, resistance, inductance and capacitance are

factors which have to be considered in the design of an IS circuit. Consultation with the

characteristic ignition curves given in the construction standard (shown in this unit on pages

9, 12 and 13), and the application of appropriate safety factors, will ensure that safe values

are established for these parameters during the design stage.

An IS system, which usually comprises a safe to hazardous area interface, cables, junction

boxes and field (hazardous) area apparatus, must also be designed in such a way as to

guard against the possibility of particular faults occurring. In contrast to other methods of

explosion protection, intrinsic safety is a system concept which applies to the whole

system and not to any one item only. Apparatus in the safe area, namely the interface,

connected to apparatus in the hazardous area is known as ‘associated apparatus’, and

each item making up the system, other than ‘simple apparatus’, will have a Certificate of

Conformity. Associated apparatus, such as the interface is typically marked with square

[Ex ib] IIC Ex ib IIC](https://image.slidesharecdn.com/compexmanual12102-240611082352-540251e1/75/CompEx-Manual-1210-2-pdf-COMPEX-GAS-AND-VAPOURS-132-2048.jpg)

![March 2010 ©

5

brackets [Ex ia]IIC, may be used in the hazardous area if installation is within another

method of explosion protection, e.g. flameproof. Also, power supply modules supplying the

system may be installed in flameproof or pressurised Ex p enclosures if installed in the

hazardous area. An overall system certificate may cover the installation. Only the

equipment specified in the system documentation may be installed in the system.

The voltage supply to electrical apparatus, which is connected to the non-IS terminals of

associated apparatus, must not be greater than the voltage Um marked on the associated

apparatus label or specified in the system documentation. The Code of Practice BS5345

recommended this value should not exceed 250Vrms. The electrical supply prospective

short-circuit current must not be in excess of 1500A.

Advantages of IS are:

a. Live maintenance is possible

b. Cost effective – certified enclosures not required and ordinary

wiring may be used

c. Safe – low voltage not harmful to personnel

d. Can be used in Zone 0

Interface types

Interface types include the zener shunt diode barrier, described below, and the galvanic

isolator described on page 18. The purpose of the interface is to prevent high energy levels

entering the hazardous area and not to protect the hazardous area equipment to which it is

connected.

The Zener Barrier

The faults which can jeopardise the security of IS systems are either overvoltage or

overcurrent, and protection against these conditions is afforded by the use of an interface,

typically a Zener barrier, the construction of which will be considered in terms of its individual

components.

The interface, which is connected between the safe area and hazardous area apparatus, is

normally located in the safe area and situated as close as possible to the boundary with the

hazardous area, but may be located in the hazardous area if installed in a flameproof

enclosure.

A simple zener barrier has three principal components, (1) a resistor, (2) a zener diode, and

(3) a fuse, all of which must have infallible properties.](https://image.slidesharecdn.com/compexmanual12102-240611082352-540251e1/75/CompEx-Manual-1210-2-pdf-COMPEX-GAS-AND-VAPOURS-133-2048.jpg)

![March 2010 ©

8

fault. A third zener diode connected in parallel with the other two will satisfy the conditions

for category ‘ia’ intrinsic safety in which safety is assured with two faults.

Category ‘ib’ intrinsic safety may be used in Zones 1 & 2, but not Zone 0, and category ‘ia’

intrinsic safety is permitted in Zones 0, 1 and 2.

Note 1: A simple test to verify if the fuse of a zener barrier has blown is to disconnect both

the input and output and measure the resistance between the input and output

terminals.

Note 2: Equipment in the hazardous area connected to Associated equipment in the non-

hazardous area must be compatible, e.g. the same group and level of protection.

If, for example, a zener barrier was marked [Ex ib] IIC and the equipment in the

hazardous area marked Ex ia IIC, the level of protection would be reduced to ib.

Minimum Ignition Current Curves

Since it is necessary to limit the voltage and current in an IS circuit to ensure operational

safety, the design of the circuit will be based on the minimum ignition current curves given in

the construction standard and reproduced on page 9. Pages 12 and 13 also illustrate the

curves for determining the maximum circuit inductance and capacitance respectively.

Resistive Circuits

For a purely resistive circuit, if the voltage is known, the maximum circuit current can be

determined from the graph, which enables selection of the correct interface.

Thus, for a purely resistive circuit for operation in a IIC hazard, it is intended that a 28 V,

300 Ω zener barrier will be used. A safety factor of 10% must be applied to the voltage of

this device since a rise in its temperature may raise the triggering voltage of the zener

diodes. Applying the safety factors of 10% (1.1 x 28 V = 30.8 V) produces a value of 30.8 V,

which is then located on the horizontal (voltage) axis of the graph.

Moving vertically from this point towards the IIC curve, and then moving horizontally from the

point of contact with the curve towards the vertical (current) axis, gives a safe current of

140 mA. A safety factor of 1.5 must be applied to this value, i.e. 2/3 of 140mA is equal to

93.33 mA. By applying ohm’s law, 28V/93.33 mA = 300 Ω, the same resistance as the zener

barrier, it has been verified that the 28V, 300 Ω interface is suitable for maintaining the

integrity of the IS circuit in a IIC hazard.](https://image.slidesharecdn.com/compexmanual12102-240611082352-540251e1/75/CompEx-Manual-1210-2-pdf-COMPEX-GAS-AND-VAPOURS-136-2048.jpg)

![March 2010 ©

10

Simple Apparatus

The spark energy of an IS circuit, during normal or fault conditions, will be insufficient to

cause ignition of a surrounding hazard. The introduction of a switch, which in normal

operation produces sparks and does not dissipate power, will not alter the situation, and in

fact, any device which is resistive by nature and non-energy storing may, theoretically, be

added to the circuit without jeopardising the integrity of intrinsic safety.

Devices such as these are referred to as simple apparatus and do not need to be certified

or marked. Such passive devices include switches, junction boxes, terminals, potentiometers

and simple semiconductor devices. Simple apparatus may also include sources of stored

energy, for example, capacitors and inductors having well defined parameters, the value of

which must be considered during the design stage of an IS installation. Sources of

generated energy, typically thermocouples and photocells, may also be described as simple

apparatus providing they do not generate more than 1.5 V, 100mA and 25 mW. Any

capacitance or inductance in these devices must also be considered during the design stage

of an installation.

Since simple apparatus is not required to be certified, justification for its use must be

included in the system documentation.

Enclosures

The minimum ingress protection for enclosures if IS circuits is IP20, but environmental

conditions may require a higher rating. As indicated in ‘simple apparatus’ above, enclosures

used as junction boxes are not required to be certified for use in hazardous areas but must

be marked that they contain IS circuits as illustrated below.

Enclosures, however, containing components with, for example, a non-IS input/IS output,

typically a zener barrier, may be installed in a flameproof enclosure for use in an hazardous

area. The marking on such an enclosure would be, for example, Ex d [ia].

Energy Storage

Energy storing devices such as inductors and capacitors have the potential to upset the

security of an IS system. Energy can be stored in these devices over a period of time and

then released in a surge of greater amplitude at, for example, a break in the IS sables due to

a fault or live disconnection at terminals. This could occur regardless of the design

constraints on voltage and current, and cause ignition of a surrounding flammable gas.

Measures must, therefore, be applied to counteract this problem at the design stage. Field

apparatus which have energy storing capability, i.e. they have some internal inductance, are

termed ‘non-simple’ and are required to be certified.

Cables, especially long runs between the interface and the apparatus in the hazardous area,

will have appreciable inductance and capacitance which must be taken into consideration at

the design stage. Energy will be stored under normal operating conditions, but will be greater

under fault conditions. The voltage will influence which parameter is predominant, i.e. for a

voltage of around 5 V, the inductance will be predominant, but at 28V, the capacitance will

be predominant.

THIS ENCLOSURE

CONTAINS IS CIRCUITS](https://image.slidesharecdn.com/compexmanual12102-240611082352-540251e1/75/CompEx-Manual-1210-2-pdf-COMPEX-GAS-AND-VAPOURS-138-2048.jpg)