15. Non Conventional Machining Processes

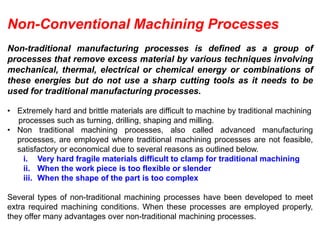

- 1. Non-Conventional Machining Processes Non-traditional manufacturing processes is defined as a group of processes that remove excess material by various techniques involving mechanical, thermal, electrical or chemical energy or combinations of these energies but do not use a sharp cutting tools as it needs to be used for traditional manufacturing processes. • Extremely hard and brittle materials are difficult to machine by traditional machining processes such as turning, drilling, shaping and milling. • Non traditional machining processes, also called advanced manufacturing processes, are employed where traditional machining processes are not feasible, satisfactory or economical due to several reasons as outlined below. i. Very hard fragile materials difficult to clamp for traditional machining ii. When the work piece is too flexible or slender iii. When the shape of the part is too complex Several types of non-traditional machining processes have been developed to meet extra required machining conditions. When these processes are employed properly, they offer many advantages over non-traditional machining processes.

- 5. Electrochemical Machining (ECM) is a non-traditional machining (NTM) process belonging to Electrochemical category. ECM is opposite of electrochemical or galvanic coating or deposition process. Thus ECM can be thought of a controlled anodic dissolution at atomic level of the work piece that is electrically conductive by a shaped tool due to flow of high current at relatively low potential difference through an electrolyte which is quite often water based neutral salt solution. Fig. schematically shows the basic principle of ECM ELECTRO-CHEMICAL MACHINING

- 6. Process During ECM, there will be reactions occurring at the electrodes i.e. at the anode or workpiece and at the cathode or the tool along with within the electrolyte. Let us take an example of machining of low carbon steel which is primarily a ferrous alloy mainly containing iron. For electrochemical machining of steel, generally a neutral salt solution of sodium chloride (NaCl) is taken as the electrolyte. The electrolyte and water undergoes ionic dissociation as shown below as potential difference is applied NaCl ↔ Na+ + Cl- H2O ↔ H+ + (OH)- As the potential difference is applied between the work piece (anode) and the tool (cathode), the positive ions move towards the tool and negative ions move towards the workpiece. Thus the hydrogen ions will take away electrons from the cathode (tool) and from hydrogen gas as: 2H+ + 2e- = H2↑ at cathode Similarly, the iron atoms will come out of the anode (work piece) as: Fe = Fe+ + + 2e-

- 7. Within the electrolyte iron ions would combine with chloride ions to form iron chloride and similarly sodium ions would combine with hydroxyl ions to form sodium hydroxide Na+ + OH- = NaOH In practice FeCl2 and Fe(OH)2 would form and get precipitated in the form of sludge. In this manner it can be noted that the work piece gets gradually machined and gets precipitated as the sludge. Moreover there is not coating on the tool, only hydrogen gas evolves at the tool or cathode. Fig. depicts the electro-chemical reactions schematically. As the material removal takes place due to atomic level dissociation, the machined surface is of excellent surface finish and stress free.

- 8. Equipment The electrochemical machining system has the following modules: • Power supply • Electrolyte filtration and delivery system • Tool feed system • Working tank

- 9. Tool material • Since the tool has no contact with the work piece, there is no tool wear. So any material that is good conductor of electricity can be used as tool material • Most commonly used tool materials are copper, brass, titanium, copper tungsten and stainless steel when the electrolyte is made of sodium or potassium Electrolyte Low electrolyte temperature results in low MRR and high temperature leads to vaporization of the electrolyte, so it’s maintained around 35ᵒC to 65ᵒC

- 10. Process Parameters • Power Supply Type direct current Voltage 2 to 35 V Current 50 to 40,000 A Current density 0.1 A/mm2 to 5 A/mm2 • Electrolyte Material NaCl and NaNO3 • Temperature: 20oC – 50oC • Flow rate: 20 lpm per 100 A current • Pressure: 0.5 to 20 bar • Dilution: 100 g/l to 500 g/l • Working gap: 0.1 mm to 2 mm • Overcut: 0.2 mm to 3 mm • Feed rate: 0.5 mm/min to 15 mm/min • Electrode material: Copper, brass, bronze • Surface roughness: Ra 0.2 to 1.5 μm

- 11. Material removal rate (MRR) is an important characteristic to evaluate efficiency of a non-traditional machining process. In ECM, material removal takes place due to atomic dissolution of work material. Electrochemical dissolution is governed by Faraday’s laws. The first law states that the amount of electrochemical dissolution or deposition is proportional to amount of charge passed through the electrochemical cell, which may be expressed as: m∝Q, where m = mass of material dissolved or deposited and Q = amount of charge passed The second law states that the amount of material deposited or dissolved further depends on Electrochemical Equivalence (ECE) of the material that is again the ratio atomic weight and valency. Thus Thus where F = Faraday’s constant = 96500 coulombs where I = current ρ= density of the material

- 12. Advantages • No mechanical force • There is no cutting forces therefore clamping is not required except for controlled motion of the work piece. There is no heat affected zone. • Very accurate. • Relatively fast • Can machine harder metals than the tool. • Provides smooth surfaces • No need of harder material that is used in processing. • More sensitive and repeatable • Provides of processing complex geometries Disadvantages • Solution usage • Pump, tank, pipe, filter and sink usage. • Keeping the solution conductivity constant. • More expensive than conventional machining. • Need more area for installation. • Electrolytes may destroy the equipment. • Not environmentally friendly (sludge and other waste) • High energy consumption.

- 13. Applications ECM technique removes material by atomic level dissolution of the same by electrochemical action. Thus the material removal rate or machining is not dependent on the mechanical or physical properties of the work material. It only depends on the atomic weight and valency of the work material and the condition that it should be electrically conductive. Thus ECM can machine any electrically conductive work material irrespective of their hardness, strength or even thermal properties. Moreover as ECM leads to atomic level dissolution, the surface finish is excellent with almost stress free machined surface and without any thermal damage. ECM is used for • Die sinking • Profiling and contouring • Trepanning • Grinding • Drilling • Micro-machining

- 14. Electrochemical grinding is a variation of ECM that combines electrolytic activity with the physical removal of material by means of electrically charged wheels • ECG can produce burr free and stress free parts without heat or metallurgical caused by mechanical grinding , eliminating the need for secondary machining operations • Like ECM, (ECG) generates little or no heat that can distort delicate components

- 16. The wheels and work piece are electrically conductive Wheels used last for many grindings - typically 90% of the metal are removed by electrolysis and 10% from the abrasive grinding wheel Important points to be Observed on the ECG process for Successful Results •ECG equipment must be in good condition to achieve best results in electrolytic grinding •The carbide work piece should not be allowed to dwell against the wheel as this will result in pitting •The diamond wheel must be kept clean in order to maintain the proper gap between the anode and the cathode. A soft dressing stick ( aluminum oxide ) may be used for this purpose Control of Overcut in ECG Machining parameters which affect overcut in electrolytic grinding include the following a)Voltage (overcut is directly proportional) b) Current density c) Electrolyte (overcut is directly related) d) Feed rate (overcut is inversely proportional) and e)Work piece composition

- 17. Performance characteristics of ECG Process 1) Influence of contact pressure 2) Influence of grinding wheel speed 3) Influence of the D.C potential between wheel and the work piece 4) Influence of Abrasive Grain Size WHEELS FOR ECG • Diamond wheels. These wheels are used to electrochemically grind flat surfaces of tungsten carbide tools and other carbide parts. • Non-diamond-face wheels. This type of wheel is used for grinding the flat surfaces of steels and alloy steels. The abrasive used in this type of wheel has been aluminum oxide. • Non-diamond wheels. Dressable resin-bond and copper loaded wheels (Copperdyne) are used extensively for all applications other than tungsten carbide

- 19. Advantages ECG increases wheel life due to negligible wear Fixtures used for holding the components are simple in construction Cutting tools with specially shaped tips can be ground quickly No overheating occurs and hence no surface cracks are produced on parts machined by ECG A surface finish up to 0.25 micron is possible No metallurgical damage from heat Cost of grinding is reduced by 25 – 40% More precise tolerances can be obtained Disadvantages •High capital cost •Corrosive environment •High preventive maintenance costs •Not economical for soft materials •Machining of cast iron by ECG present certain difficulties •Non conducting hard work materials such as ceramics cannot be machined by ECG process

- 20. APPLICATIONS • Primarily used in the grinding of Tungsten carbide tool bits • Grinding of cutting tools, chilled iron castings , magnet alloys, contour milling of honey- comb structures •Used for machining of cemented carbides , stellites, refractory materials, stainless steel and high alloys steels without any burr •Chromium plated materials, flame hardened materials and temperature sensitive alloys can be machined without forming thermal cracks and distortion •Grinding of super alloy turbine blades •Burr free sharpening of hypodermic needles