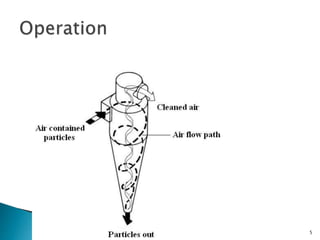

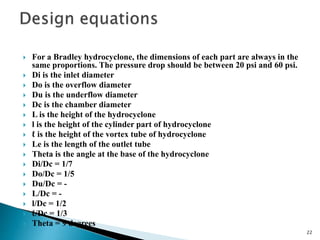

The document discusses cyclonic separators and hydrocyclones. Cyclonic separators use centrifugal force to separate particulate matter from gas streams. Gas enters tangentially and spins rapidly, forcing particles outward against the wall to fall into a collection hopper while clean gas exits through the center. Hydrocyclones separate particles in liquid suspensions based on density and size differences, with denser/coarser particles exiting the bottom and lighter/finer through the top. Both devices have various industrial uses like dust collection and mineral processing.