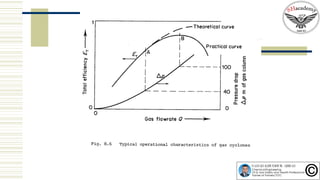

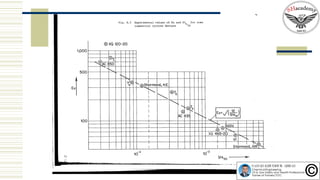

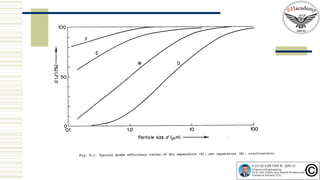

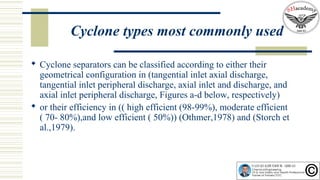

This document discusses gas-solid separation techniques, emphasizing the importance of various phases in the gas cleaning process. It details different types of gas cleaning equipment, primarily cyclone separators, including their design, operational principles, advantages, disadvantages, and key parameters affecting performance. The efficiency of separation processes, the relationship between flow rate and pressure drop, and factors for selecting appropriate equipment are also explored.

![ Figures (Othmer,

1978.) [112]

Figure a. Tangential

inlet, axial discharge.

Figure b. Tanential

inlet, peripheral

discharge

Figure c. Axial inlet,

axial discharge

Figure d. Axial inlet,

peripheral discharge](https://image.slidesharecdn.com/gassolidseparation-160411170336/85/Episode-42-Gas-Solid-Separation-15-320.jpg)