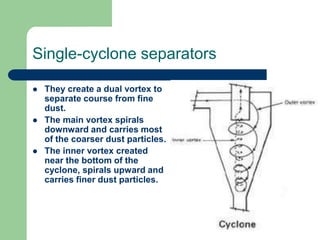

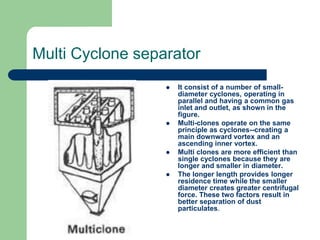

Cyclone separators use centrifugal force to remove particles from an air or gas stream. As the gas spins rapidly inside the separator, heavier particles are forced outward by centrifugal force and collect on the outer wall. There are several types of cyclones including vertical cyclones for liquid/solid removal, single cyclones that create dual vortexes to separate coarse and fine particles, and multi cyclones which consist of several small diameter cyclones operating in parallel for more efficient separation. The design of a cyclone separator is based on parameters like cylinder length, cone length, entrance/exit diameters, and collection efficiency depends on particle size, centrifugal force exerted, and time force is applied.