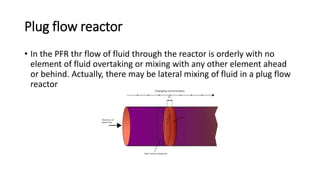

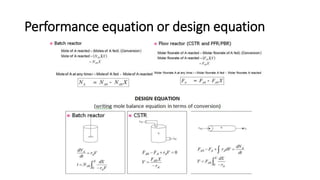

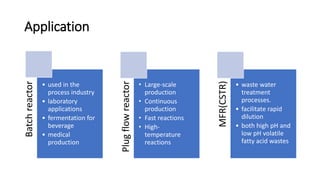

The document compares three types of reactors: batch reactors, plug flow reactors (PFR), and mixed flow reactors (CSTR). It explains that batch reactors operate in an unsteady state with time-dependent composition, PFRs maintain an orderly flow with composition varying along the length, and CSTRs are well-mixed and uniform but less efficient. Additionally, it outlines their respective applications, highlighting the use of batch reactors in laboratories and PFRs in large-scale production.