(1) A cyclone separator is needed to remove fly ash from flue gas from a power plant, with particles above 10 μm needing 99% removal and above 5 μm needing 90% removal.

(2) A cyclone with a diameter of 0.063 m was designed, which could achieve the required efficiencies. Pressure drop and other design parameters were calculated.

(3) The performance of the cyclone was analyzed through calculating particle size distribution at the inlet and outlet, showing the desired efficiencies were achieved.

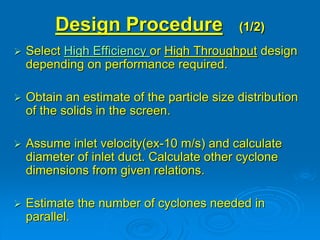

![Formulae Used

Scaling Factor (Stairmand):

[(Dc2/Dc1)3 * (Q1/Q2) *(μ1/ μ2)* ( Δρ1/ Δρ2)]0.5

Where,

Dc1: diameter of standard cyclone= 8’’ (203 mm)

Dc2: diameter of proposed cyclone,mm

Q1 : standard flow rate

for high efficiency design= 223 m3/h

for high throughput design= 669 m3/h

Δρ1: solid-fluid density difference in standard conditions= 2000 kg/m3

Δρ2 : density difference, proposed design

μ1 : test viscosity fluid (air at 1 atm, 20º C)= 0.018 mN s/m2

μ2 : viscosity, proposed fluid](https://image.slidesharecdn.com/12-ed-i-cyclone-6s-r13-240319183810-73a67ecc/85/12-ed-i-cyclone-6s-r13-ppt-cyclone-separtor-11-320.jpg)

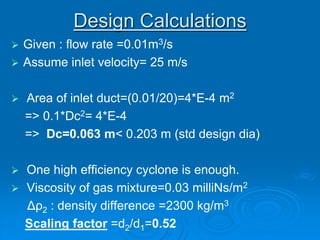

![ Pressure Drop Formula(Δp) =

(ρf /203)*{u1

2 [1+2φ2(2rt/re -1 )] + 2u2

2}

where,

Δp: pressure drop

ρf : gas density =0.8 kg/m3

u1 : inlet duct velocity

u2 : exit duct velocity

rt :radius of circle to which centre line of the inlet

is tangential

re :radius of exit pipe

Φ : Pressure drop correction factor](https://image.slidesharecdn.com/12-ed-i-cyclone-6s-r13-240319183810-73a67ecc/85/12-ed-i-cyclone-6s-r13-ppt-cyclone-separtor-15-320.jpg)