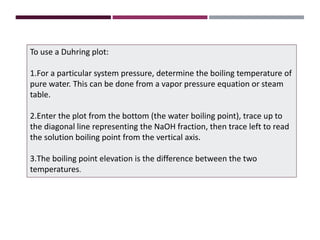

The document discusses evaporator performance and factors that affect it. It explains that the boiling point of solutions is higher than water alone, known as boiling point elevation. It also discusses how capacity, economy, and steam consumption are measures of evaporator performance. Capacity is the amount of water vaporized per hour, economy is the amount vaporized per unit of steam, and steam consumption can be estimated from capacity and economy. Duhring's rule and boiling point elevation must be considered for heat transfer calculations in evaporators dealing with solutions.