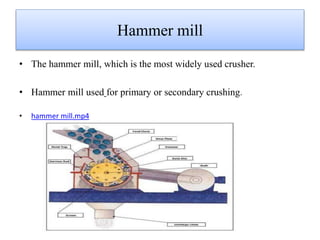

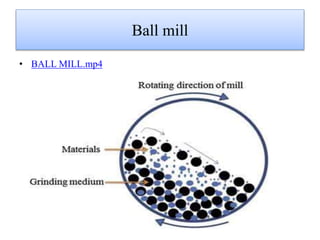

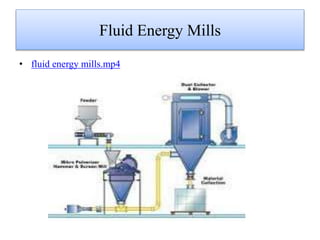

The document discusses various types of size reduction equipment used in mining and manufacturing processes. It describes crushers which use compression forces to reduce large solid materials into smaller particles ranging from 150-250mm. Specific crushers covered include jaw, gyratory, and roll crushers. Grinders further reduce particle sizes down to 74-350um using different grinding mechanisms like hammer mills, ball mills, and rolling compression mills. Ultra fine grinders can process materials into micron-sized particles from 1-50um using technologies such as agitated mills or fluid energy mills. Cutting machines also aid size reduction from 2-10mm using knife, cutter, or slitter tools.