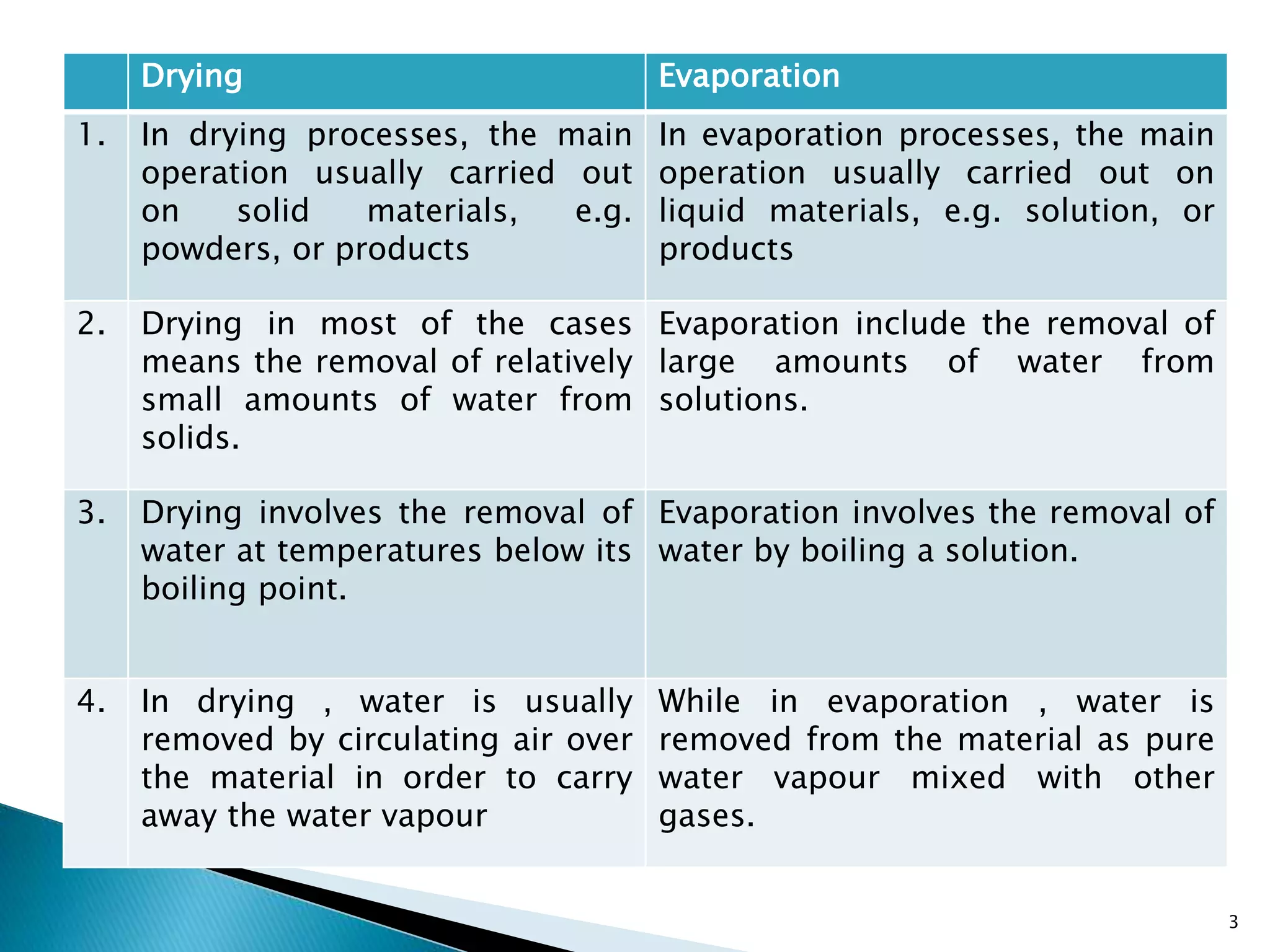

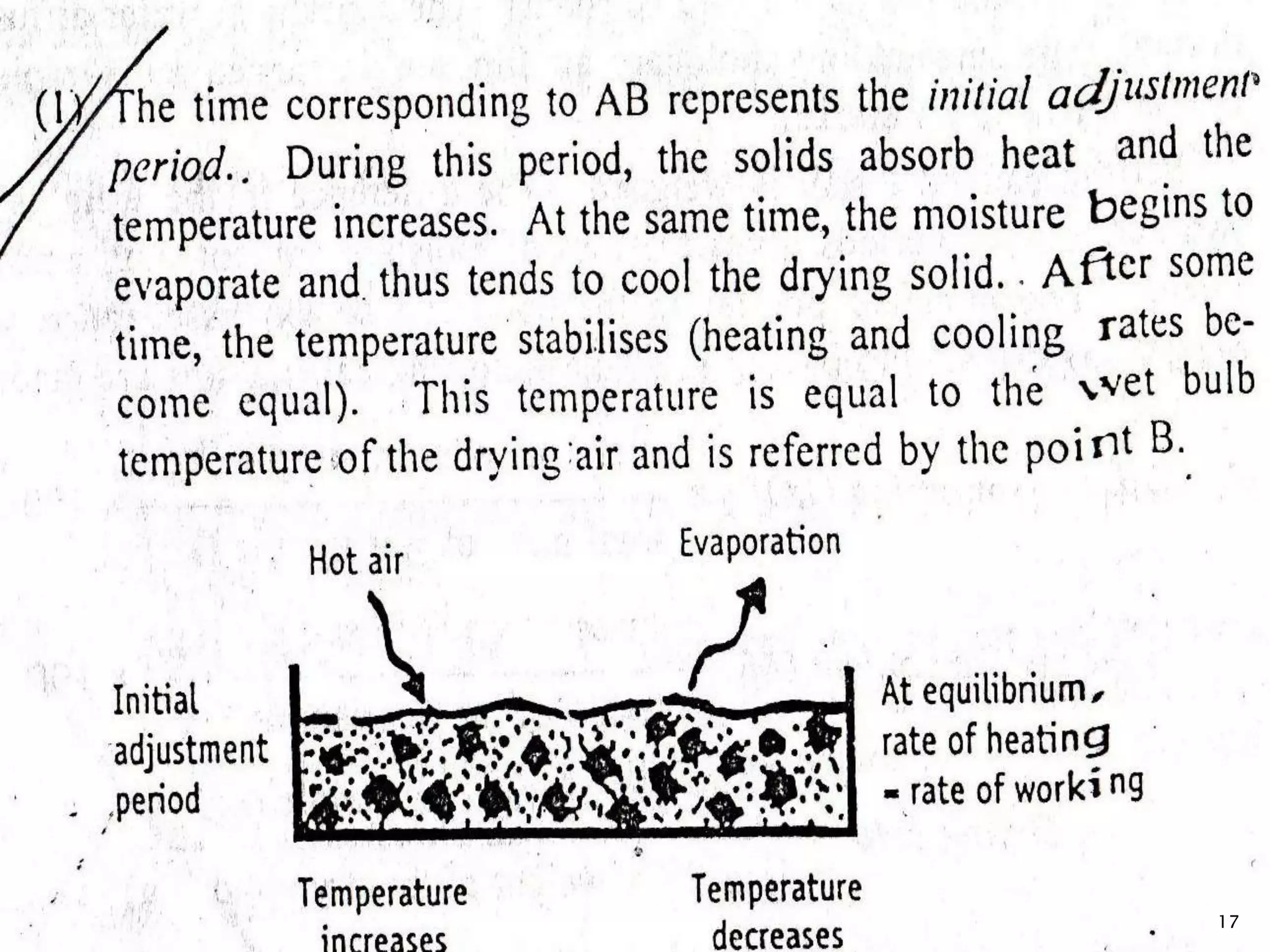

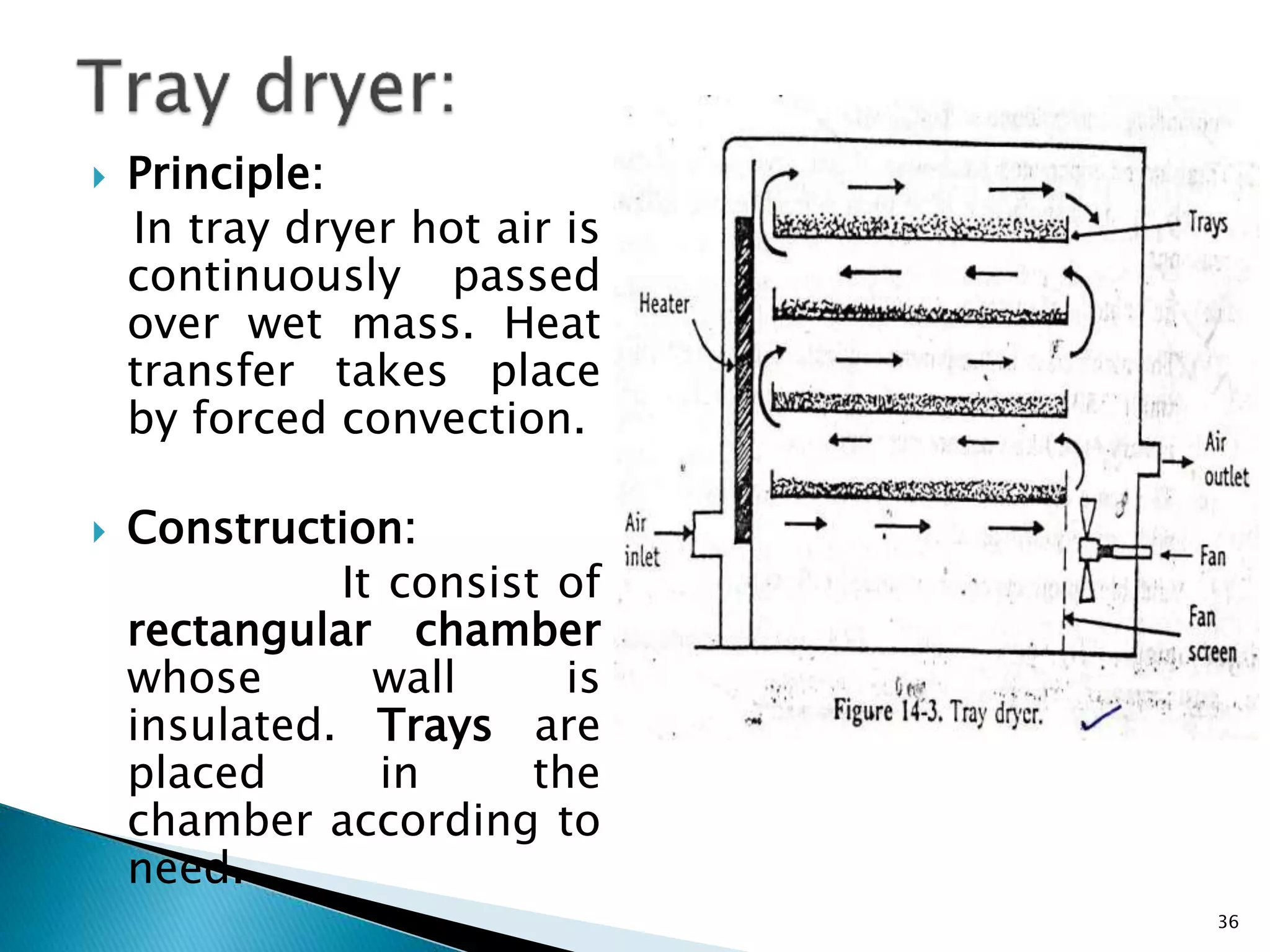

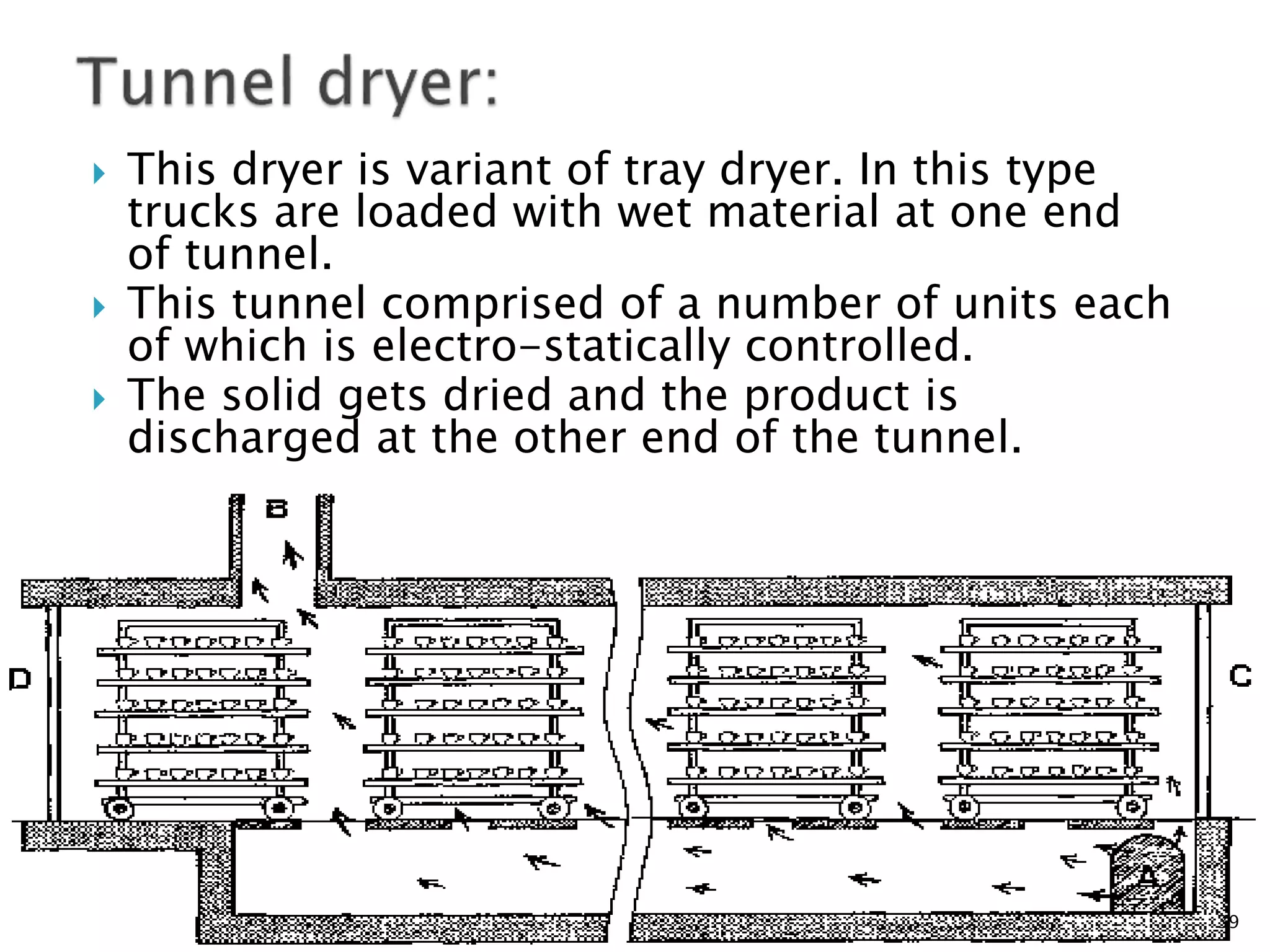

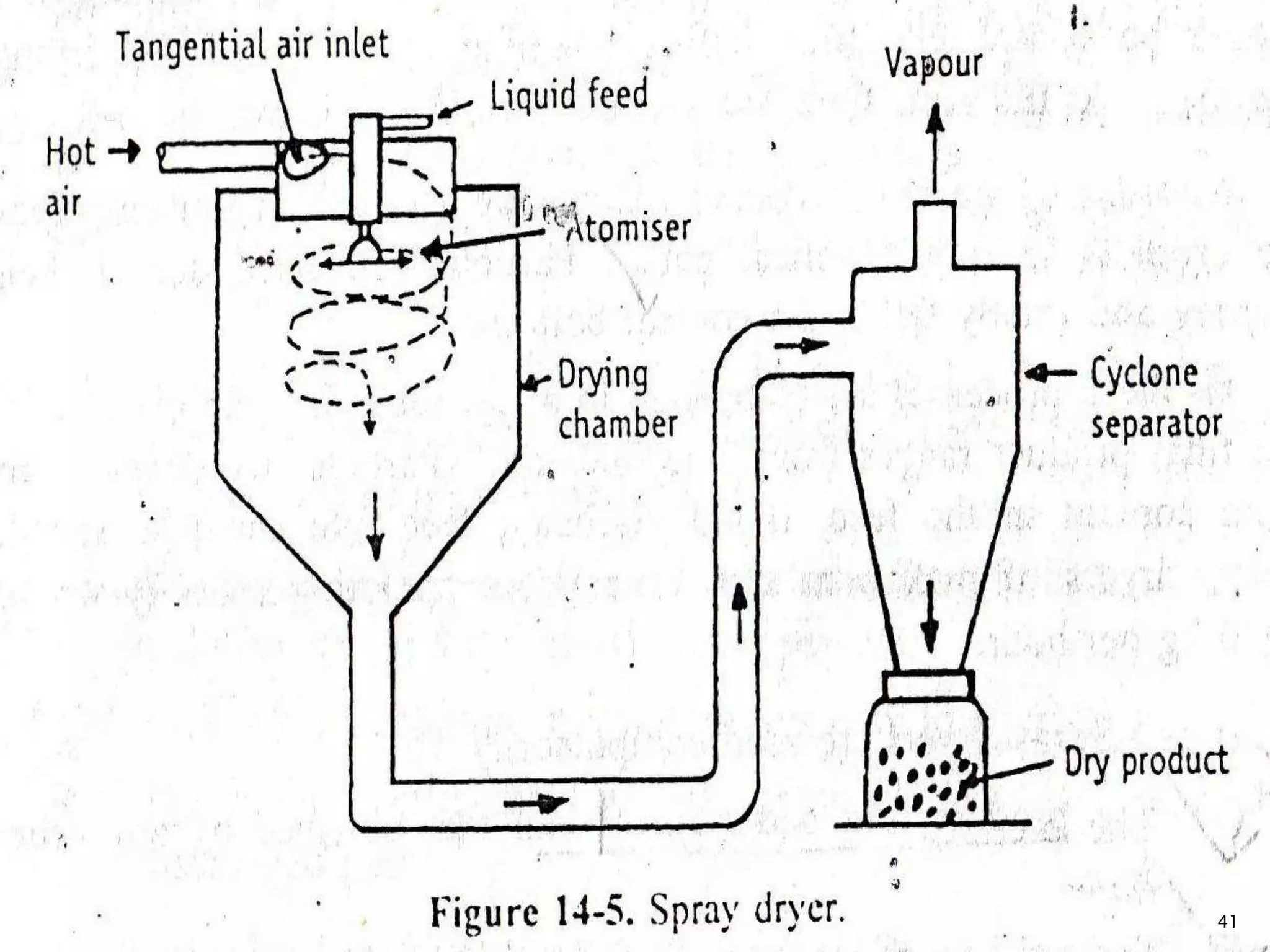

The document discusses the drying process, highlighting the removal of moisture from solid materials through heat application, distinguishing between drying and evaporation. It outlines the importance of drying in drug preservation, improving material characteristics, and reducing transportation costs, while also delving into drying principles, methods, and equipment. Various drying methods such as drum, tray, spray, fluidized bed, vacuum, and freeze drying are described, focusing on their principles, constructions, and workings.