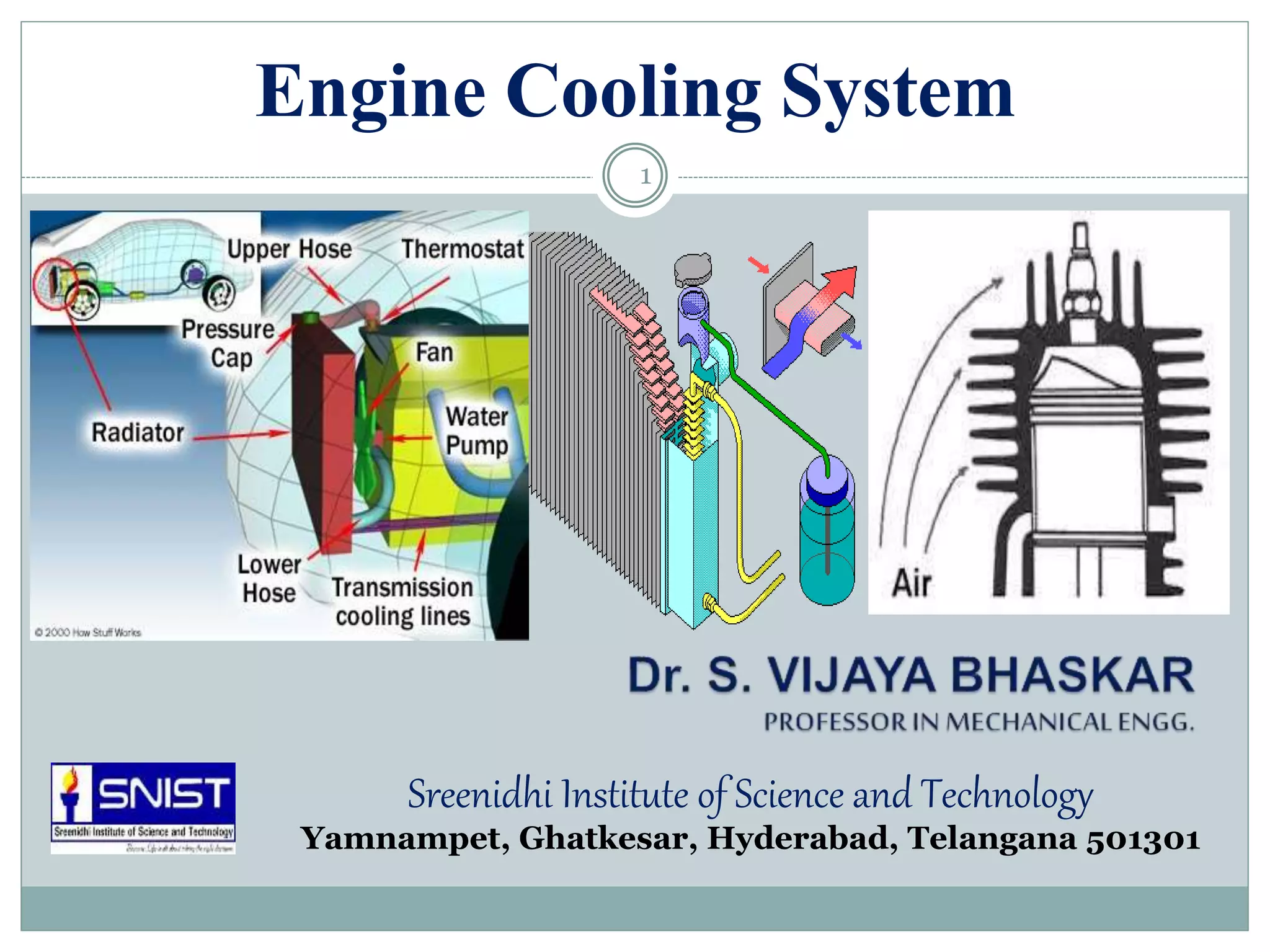

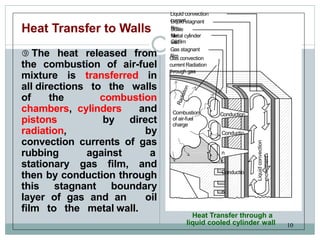

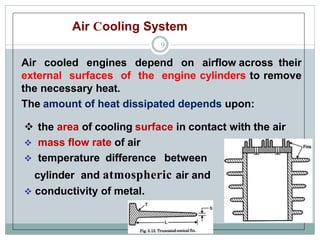

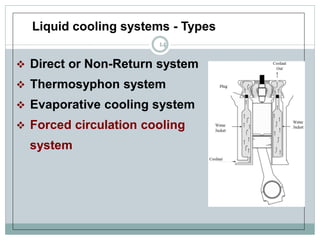

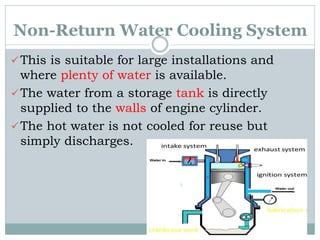

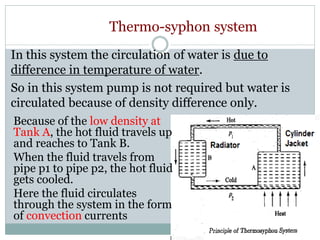

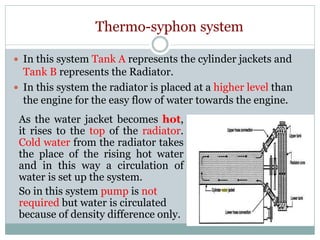

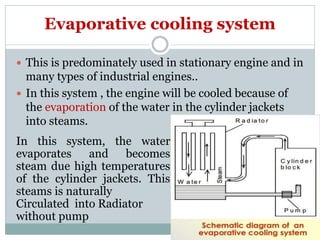

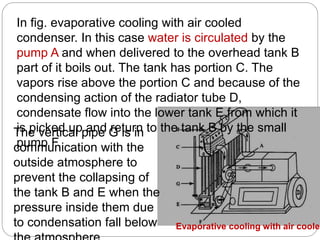

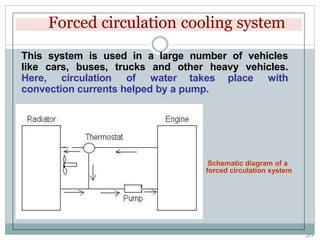

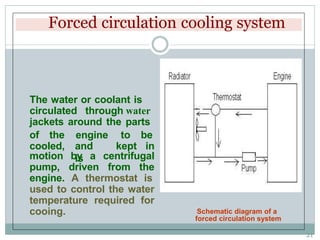

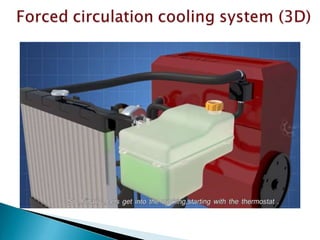

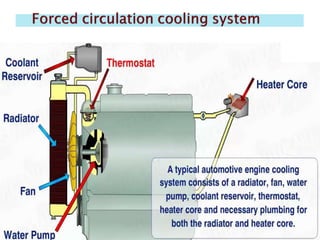

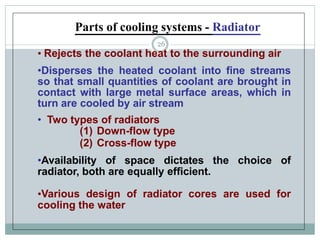

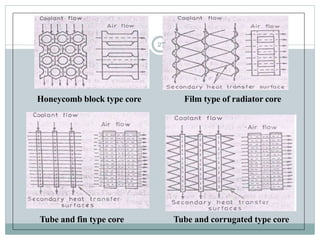

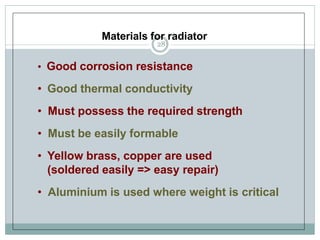

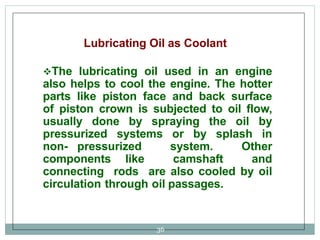

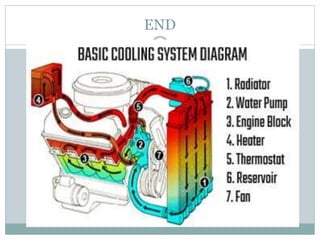

The document discusses the engine cooling system. It begins by explaining how heat is transferred from the combustion chamber through radiation, convection of gas, and conduction. It then describes the need for a cooling system to maintain optimal engine temperatures and prevent overheating. The main types of cooling systems - air cooling and liquid cooling - are presented. For liquid cooling, different circulation systems like thermosyphon and forced circulation are defined. The roles of key components like the radiator and coolant are also summarized.