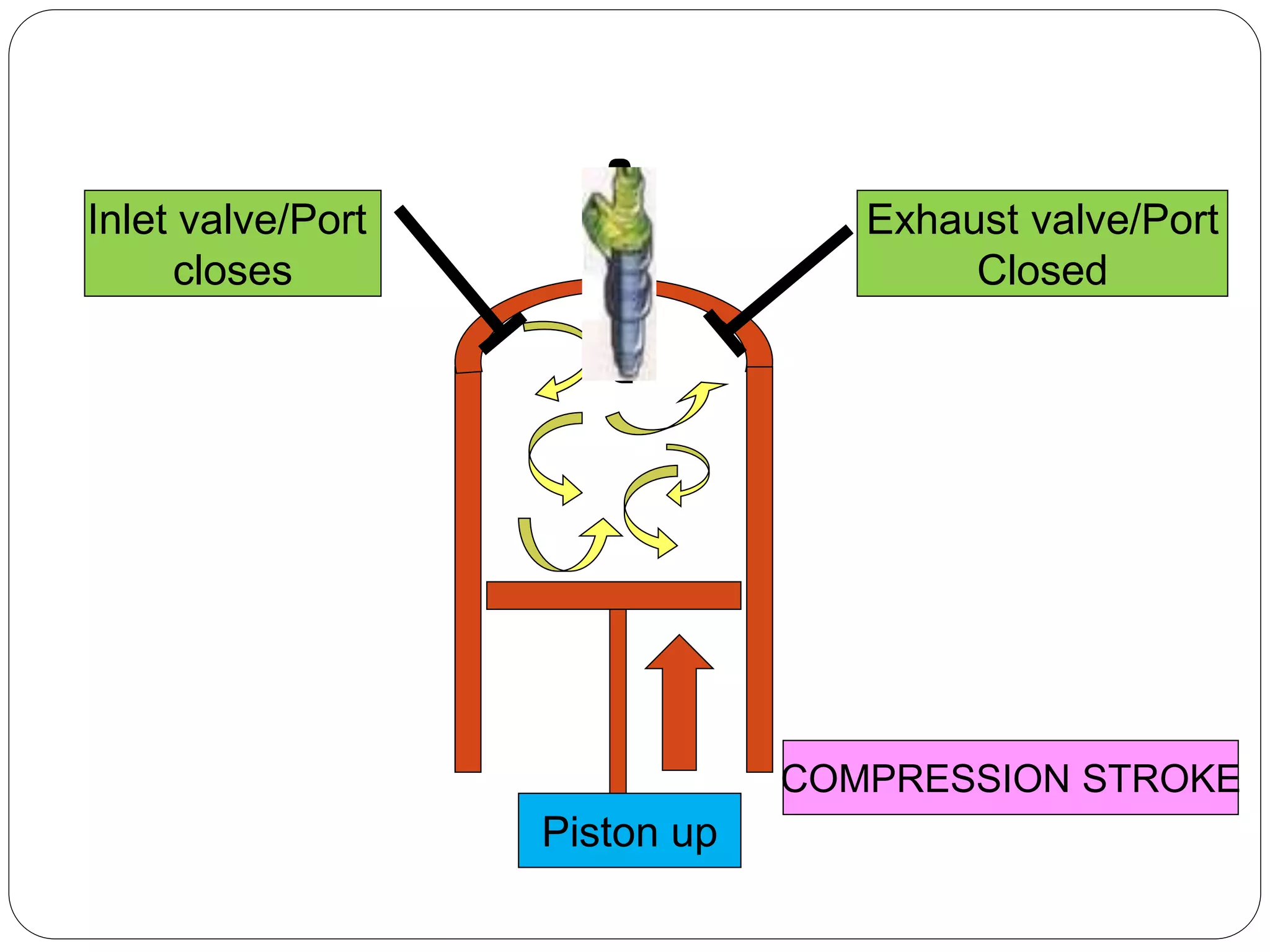

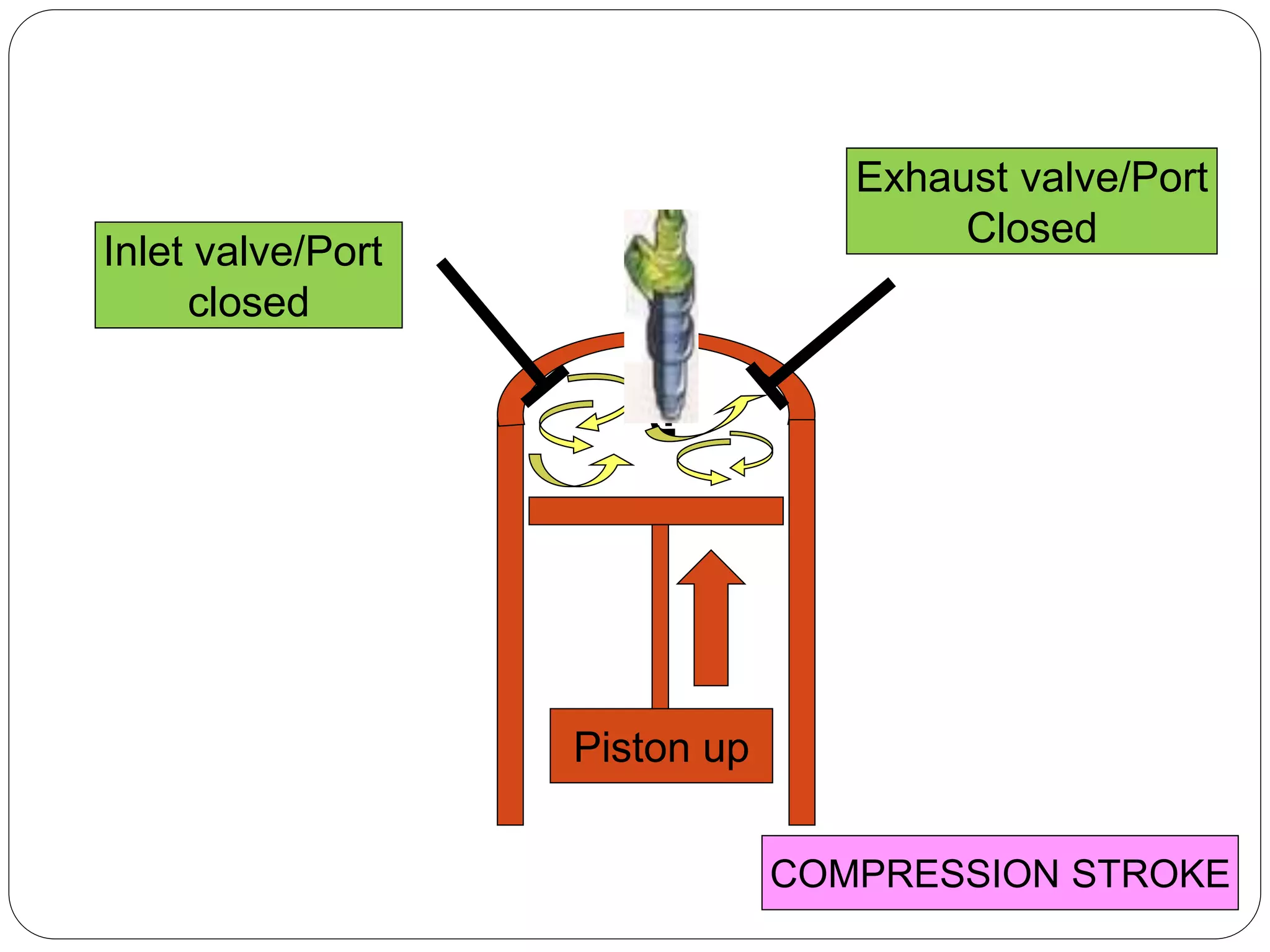

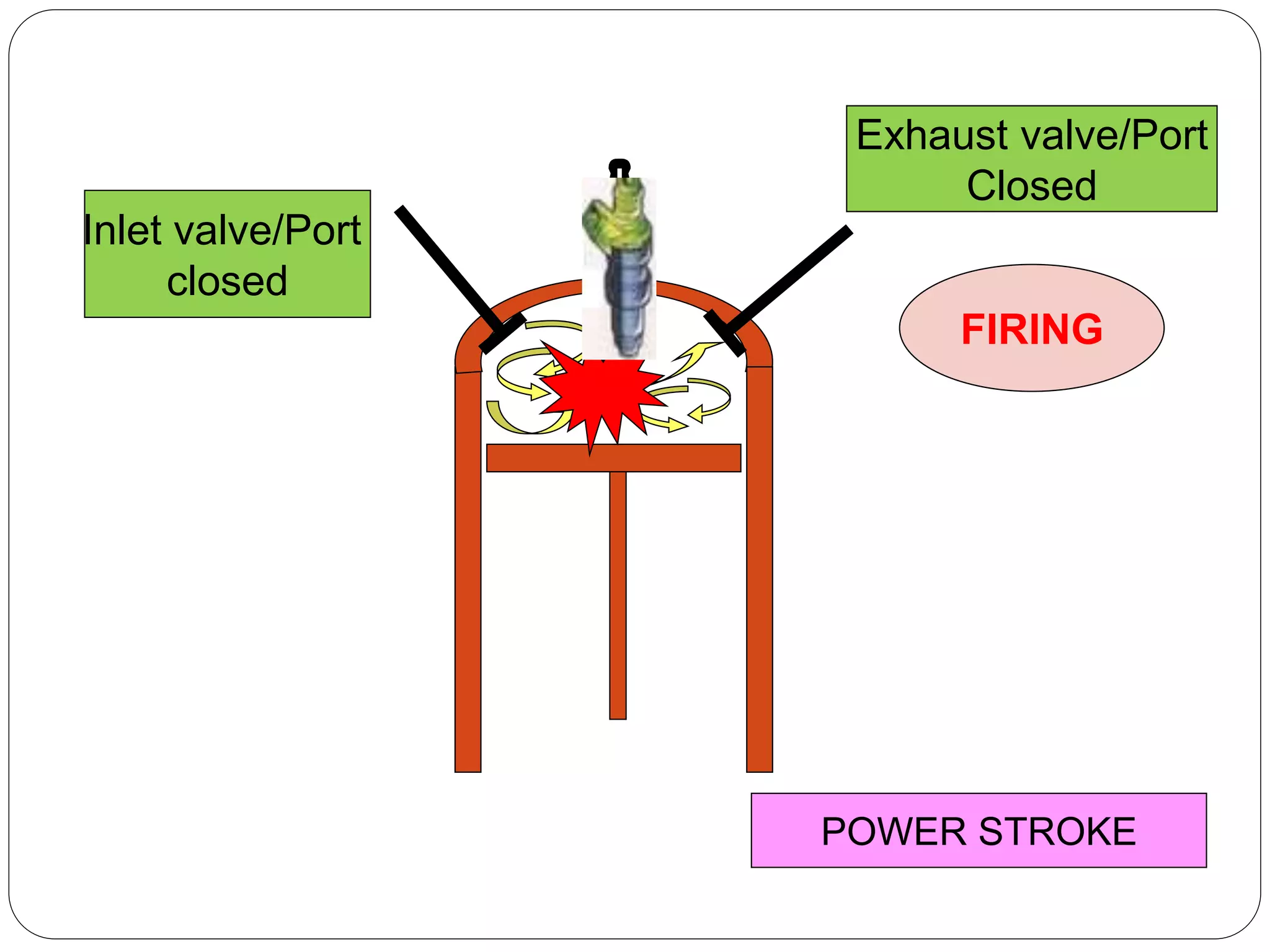

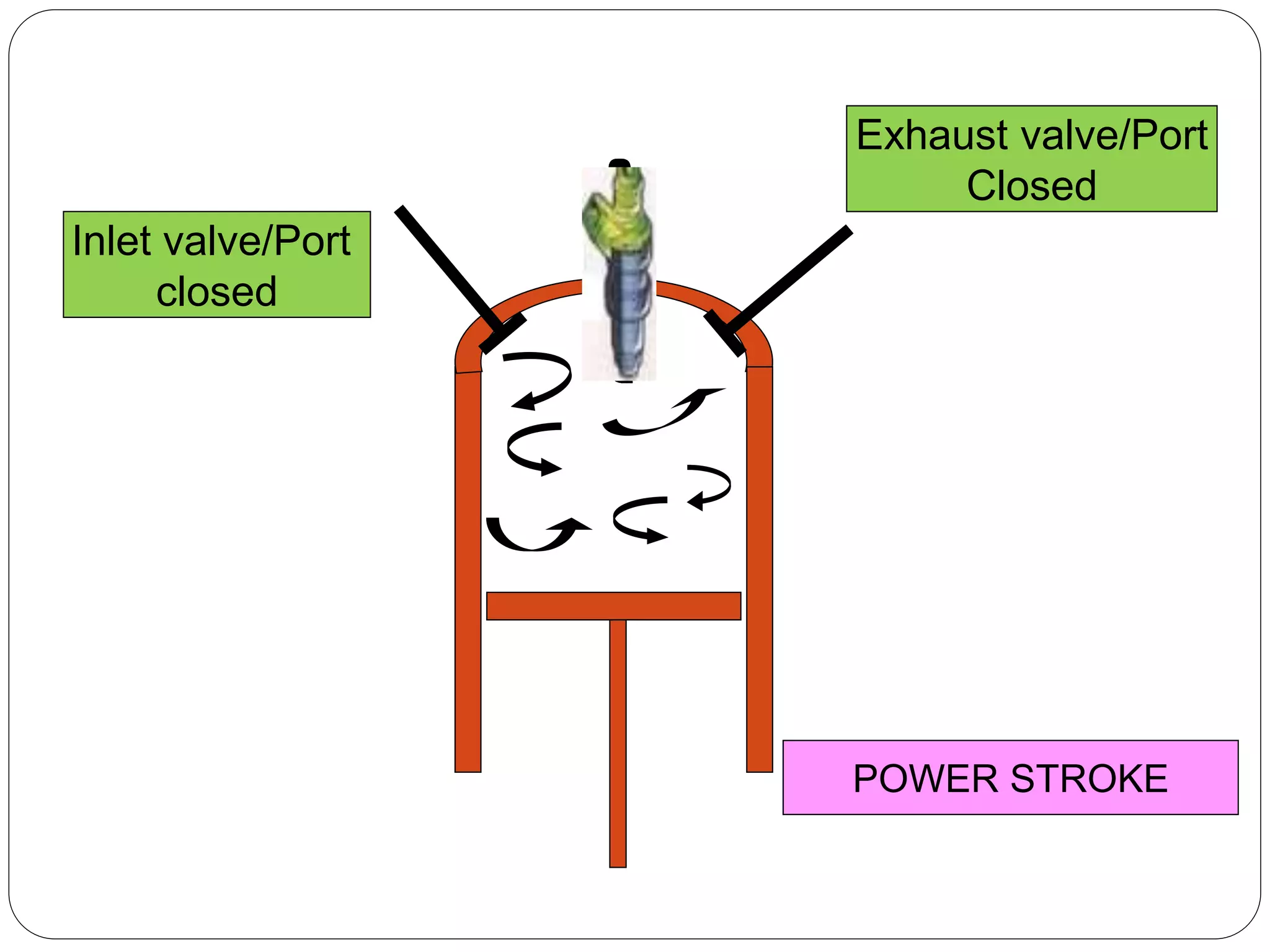

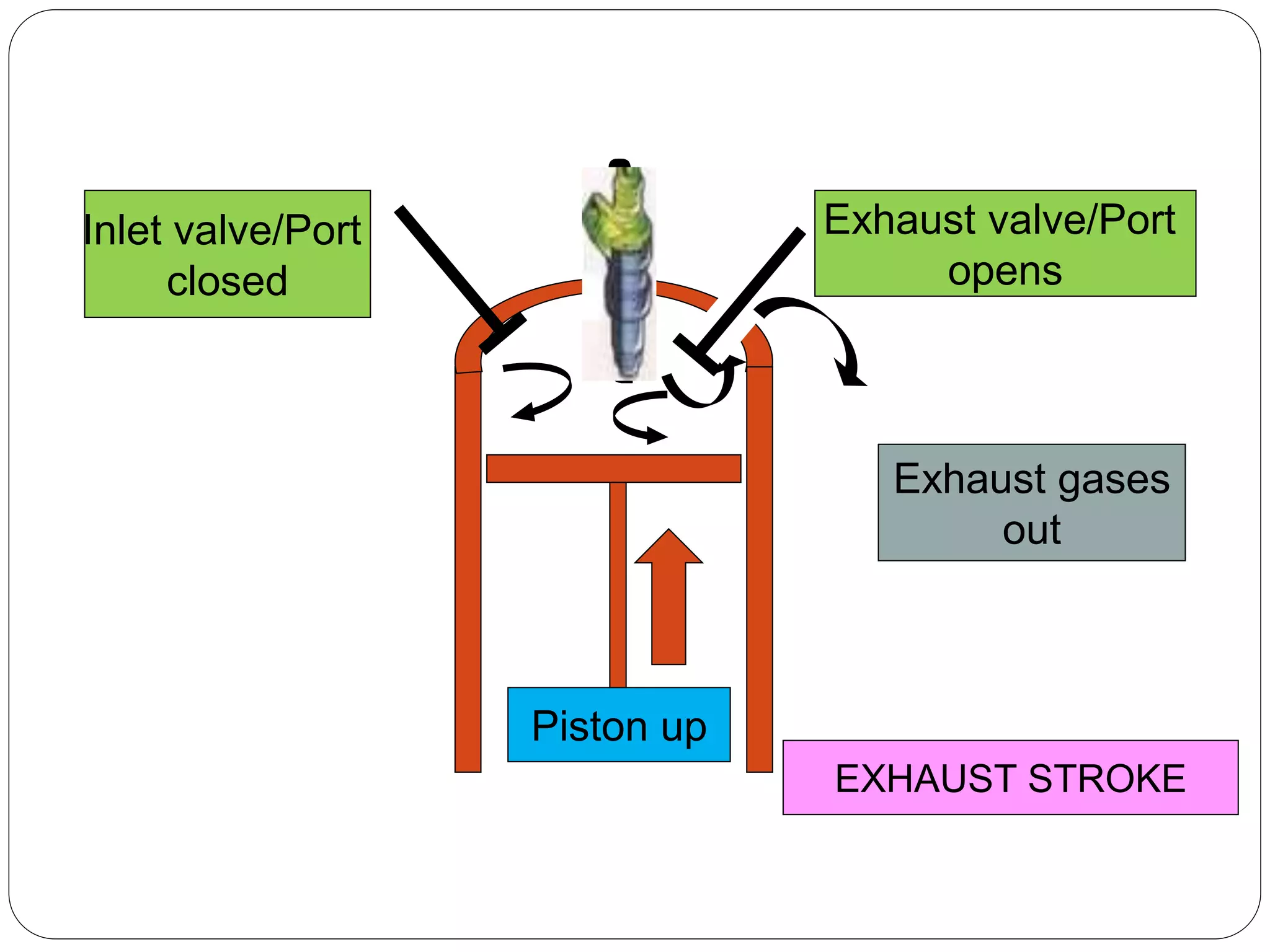

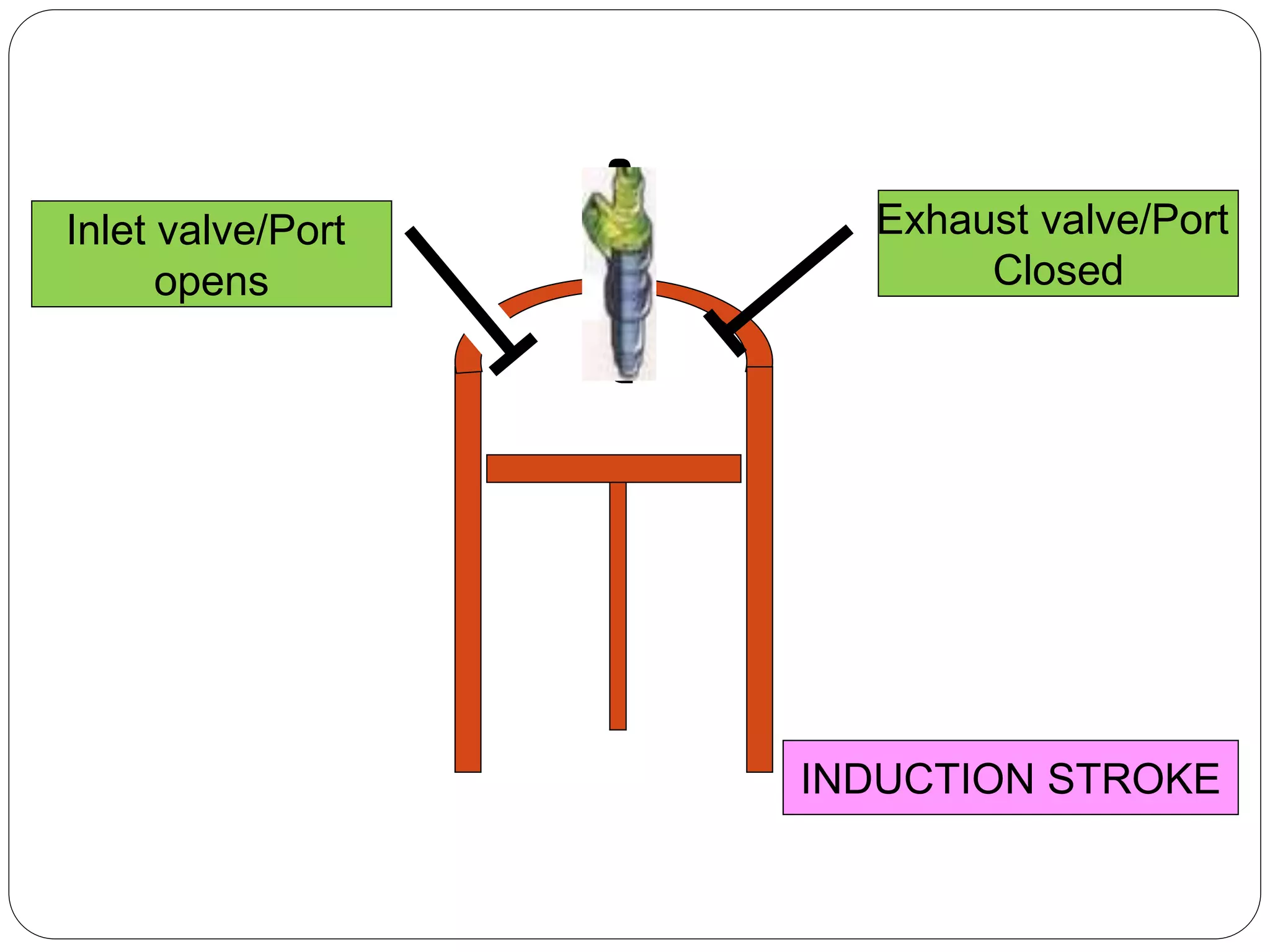

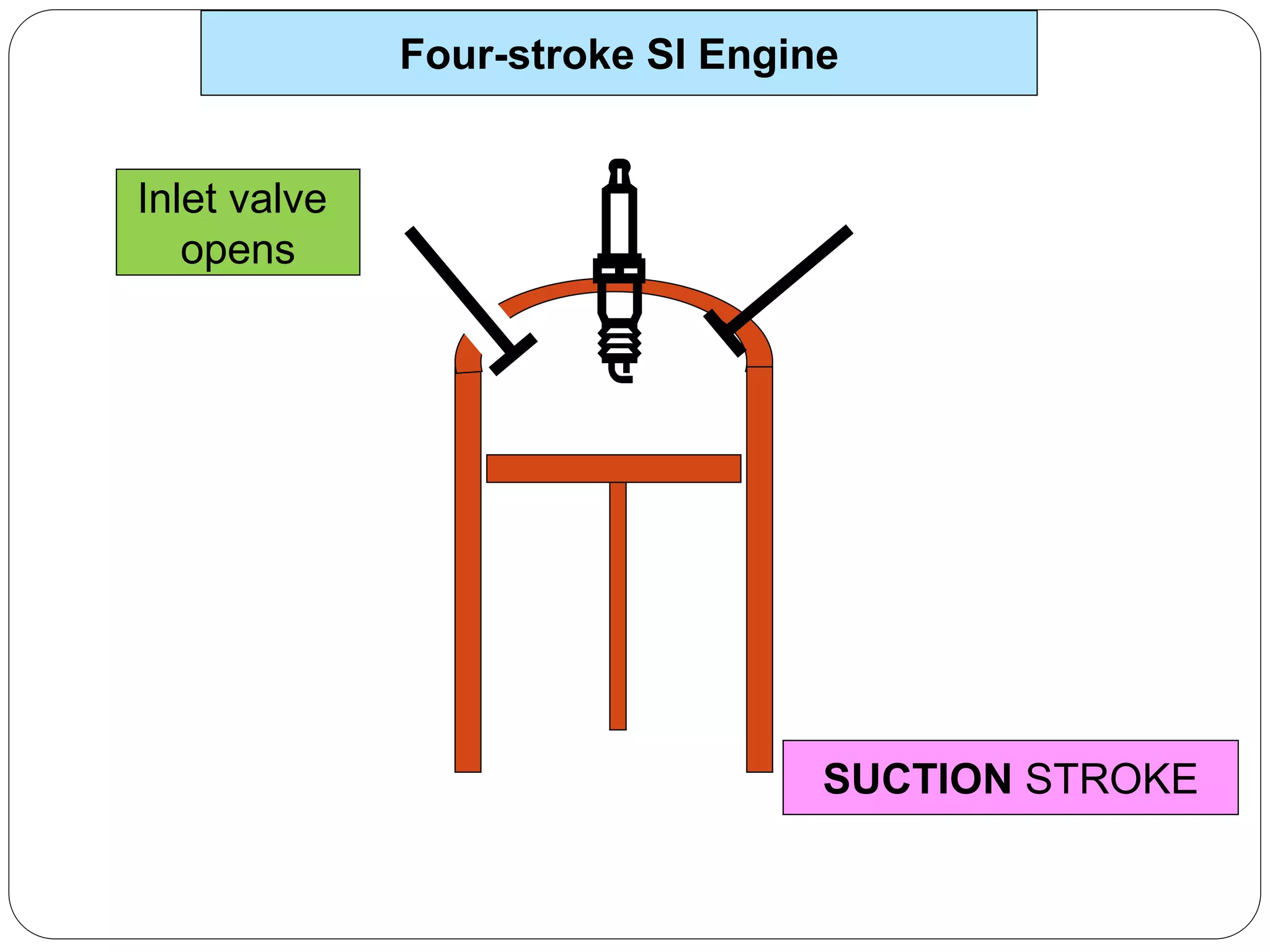

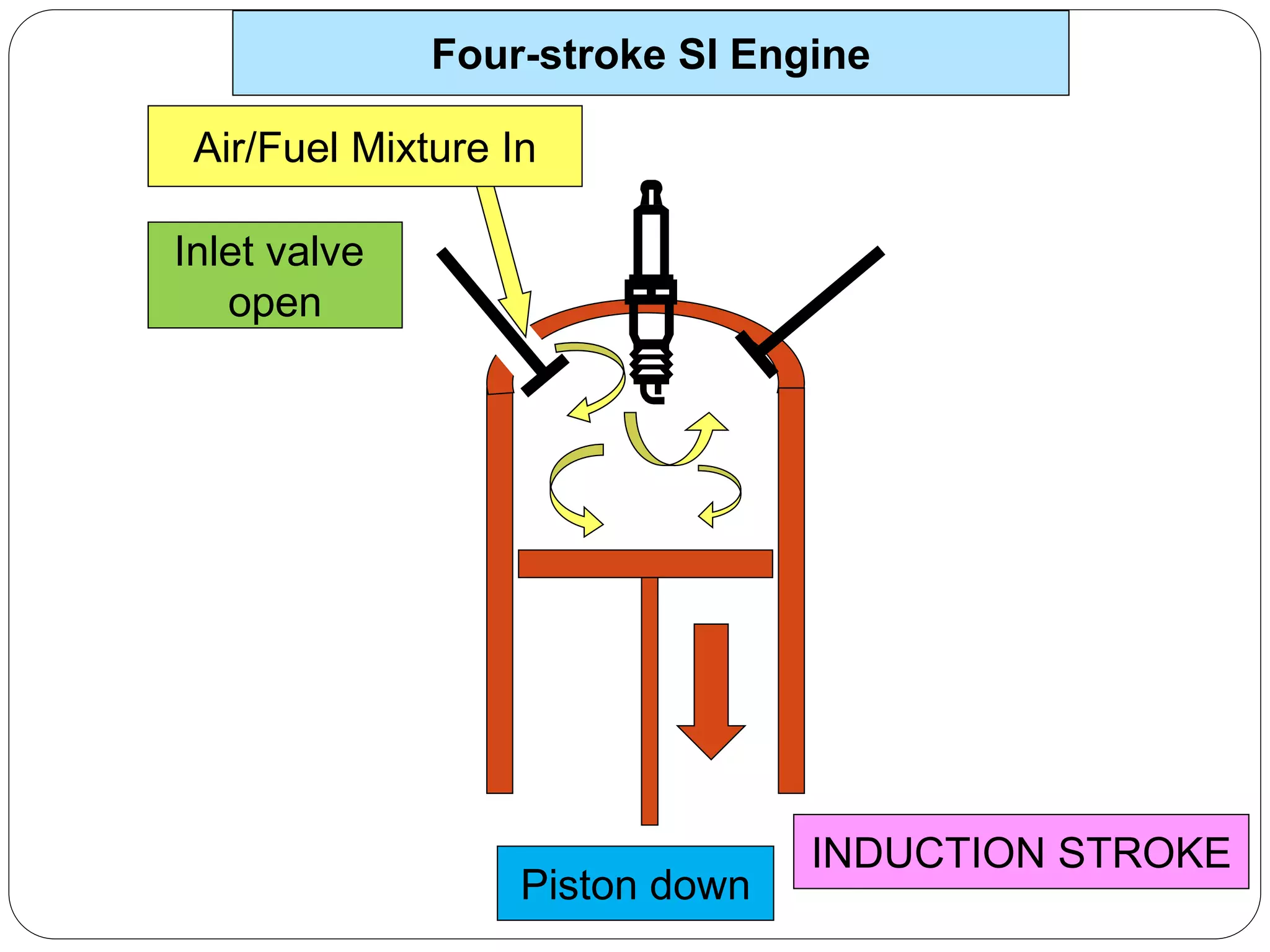

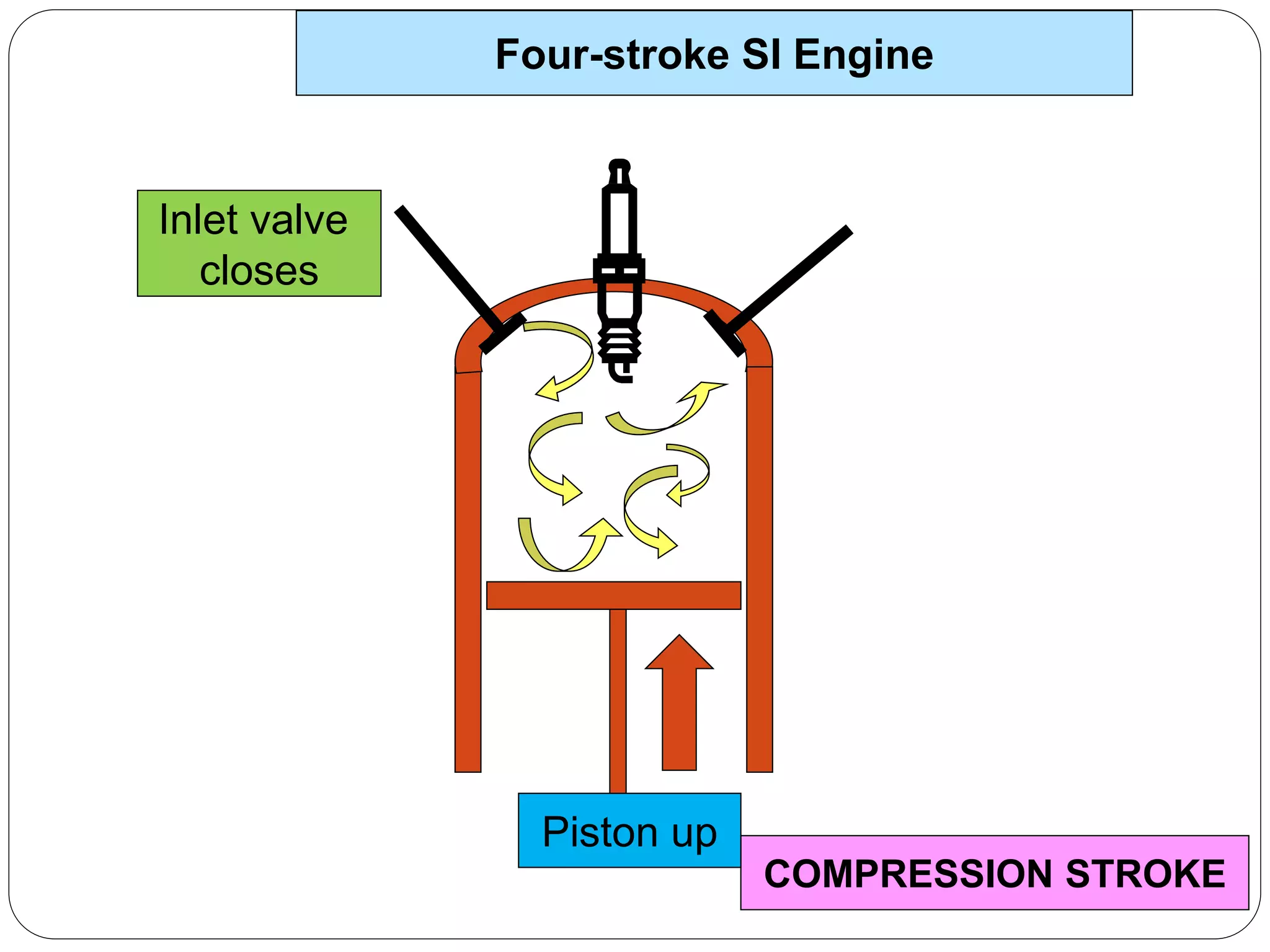

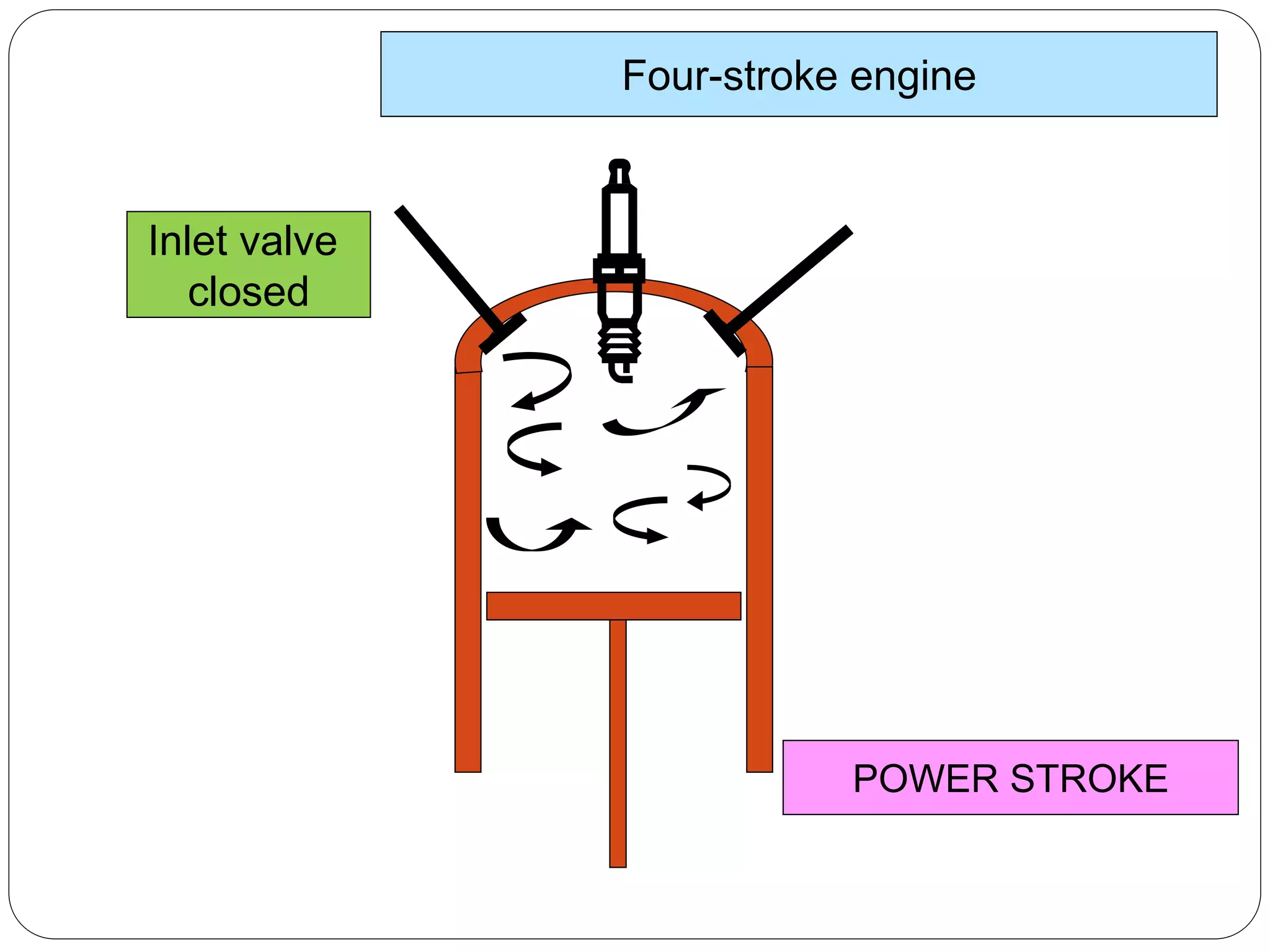

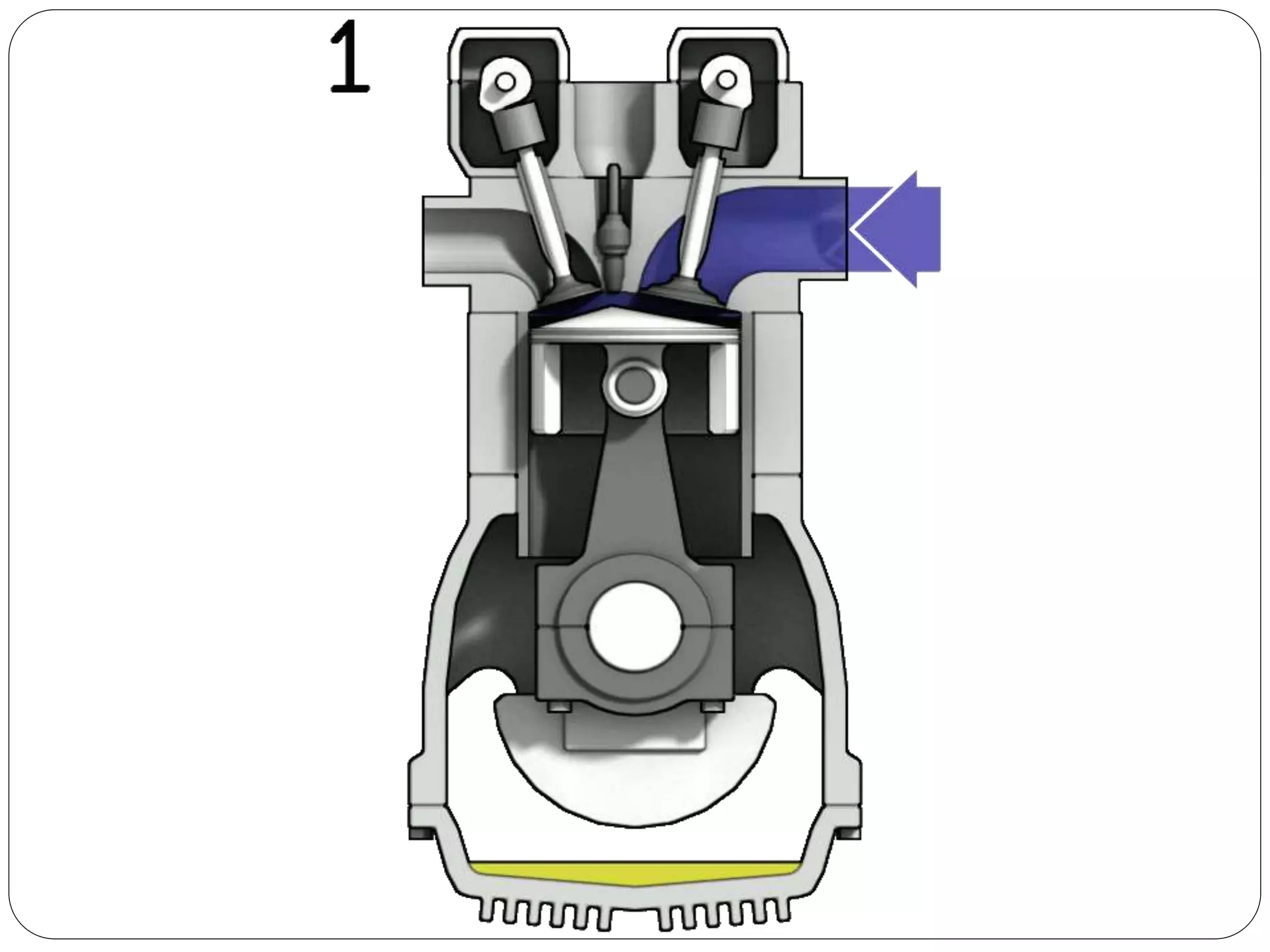

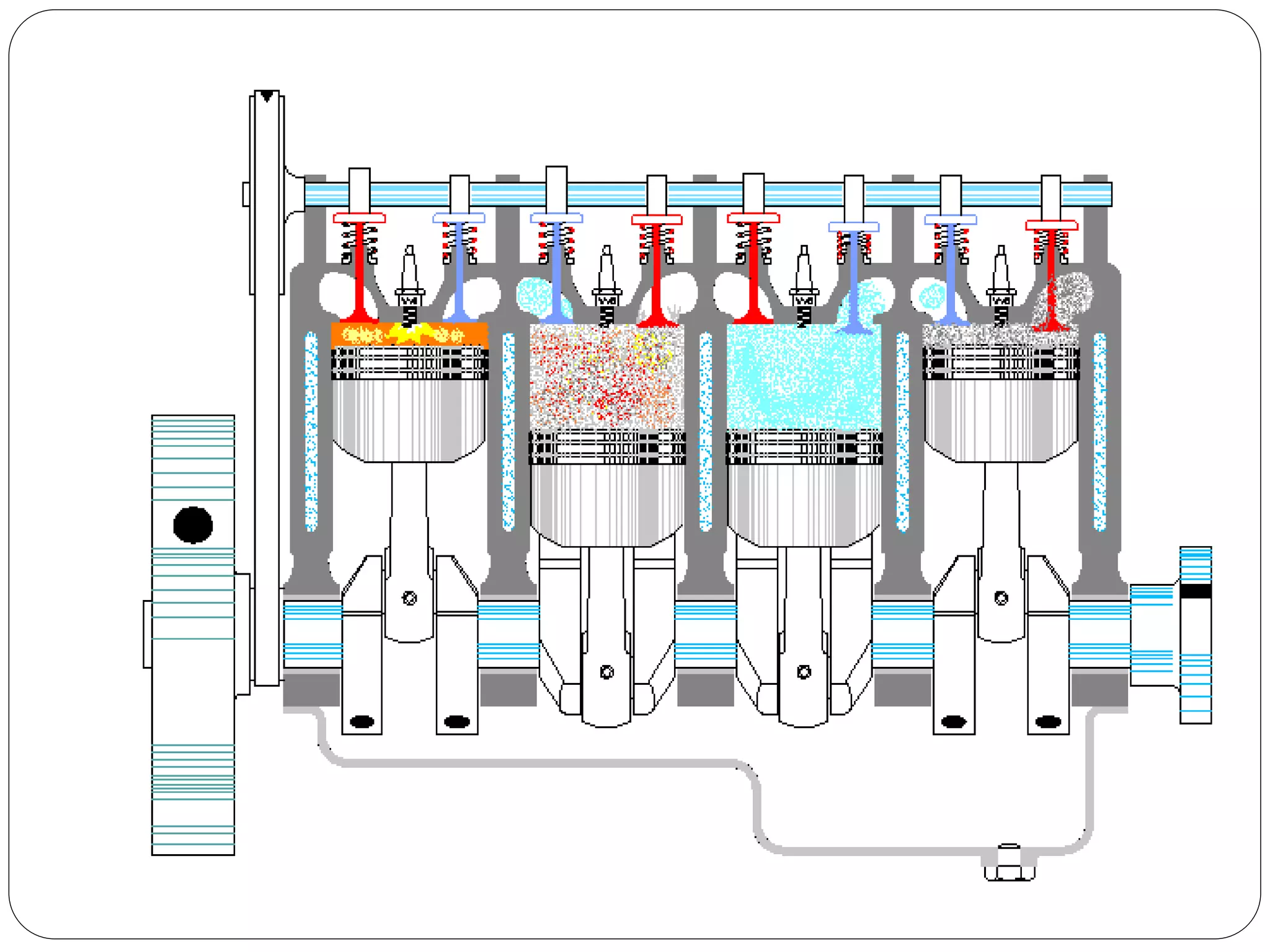

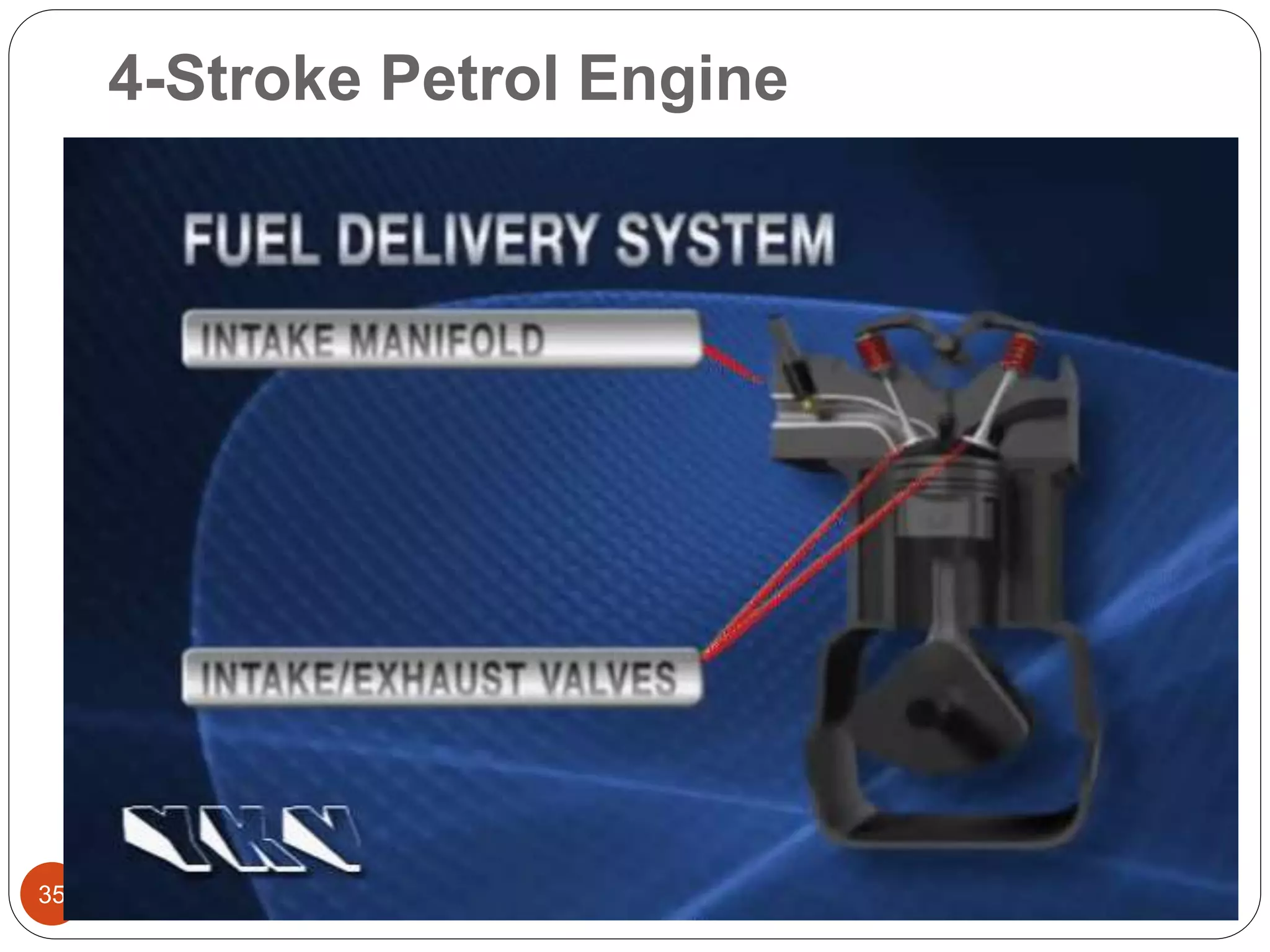

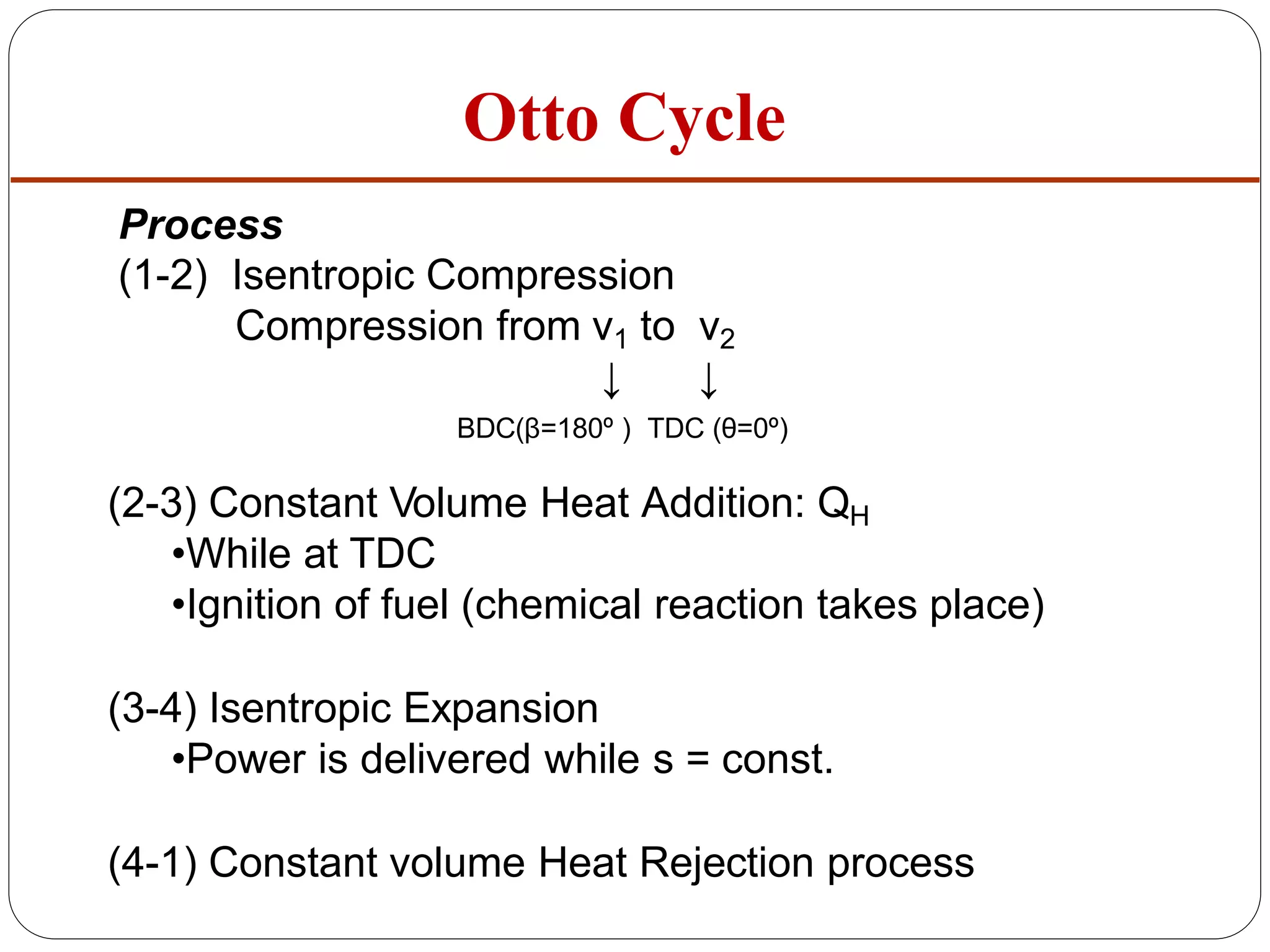

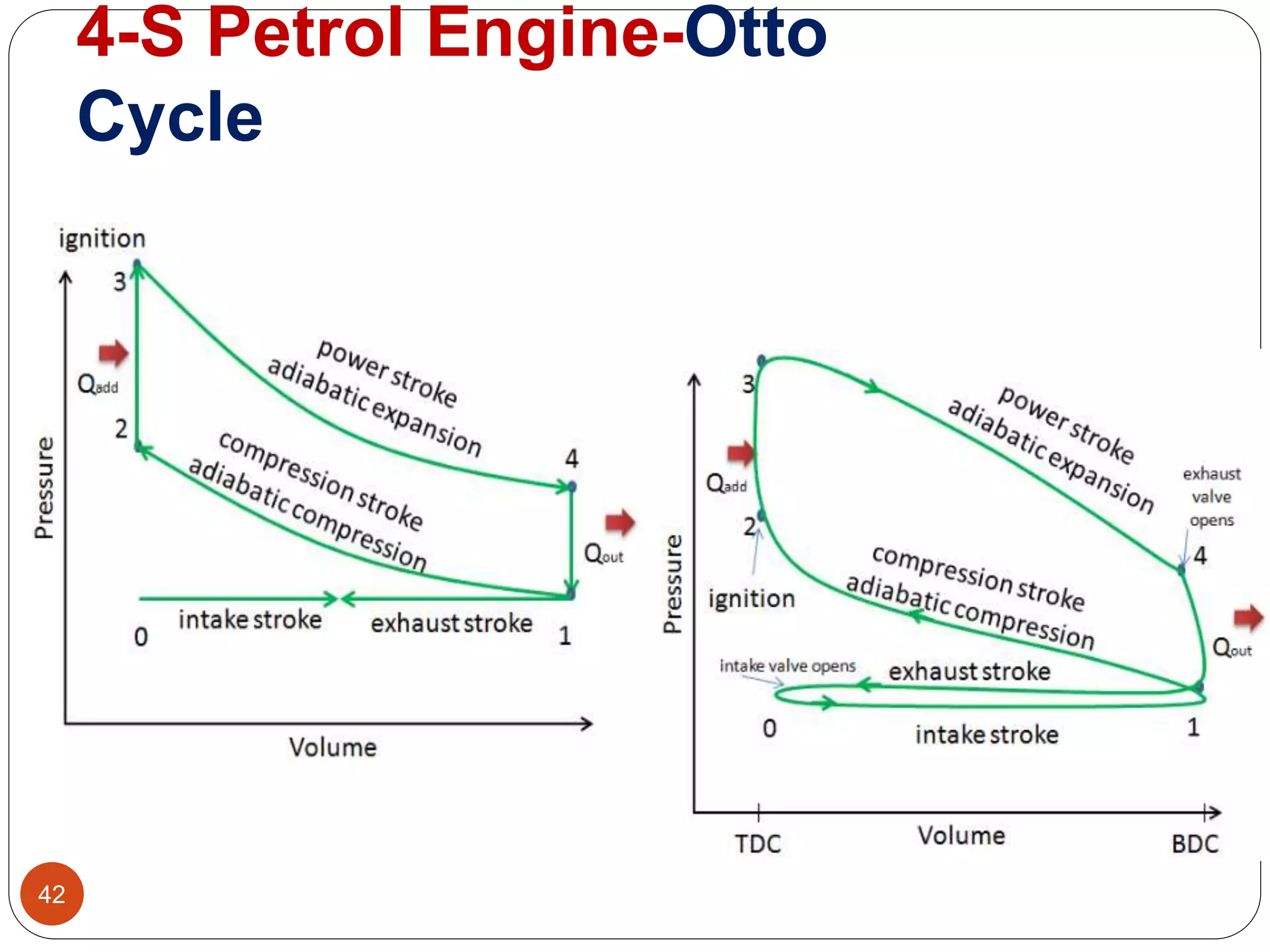

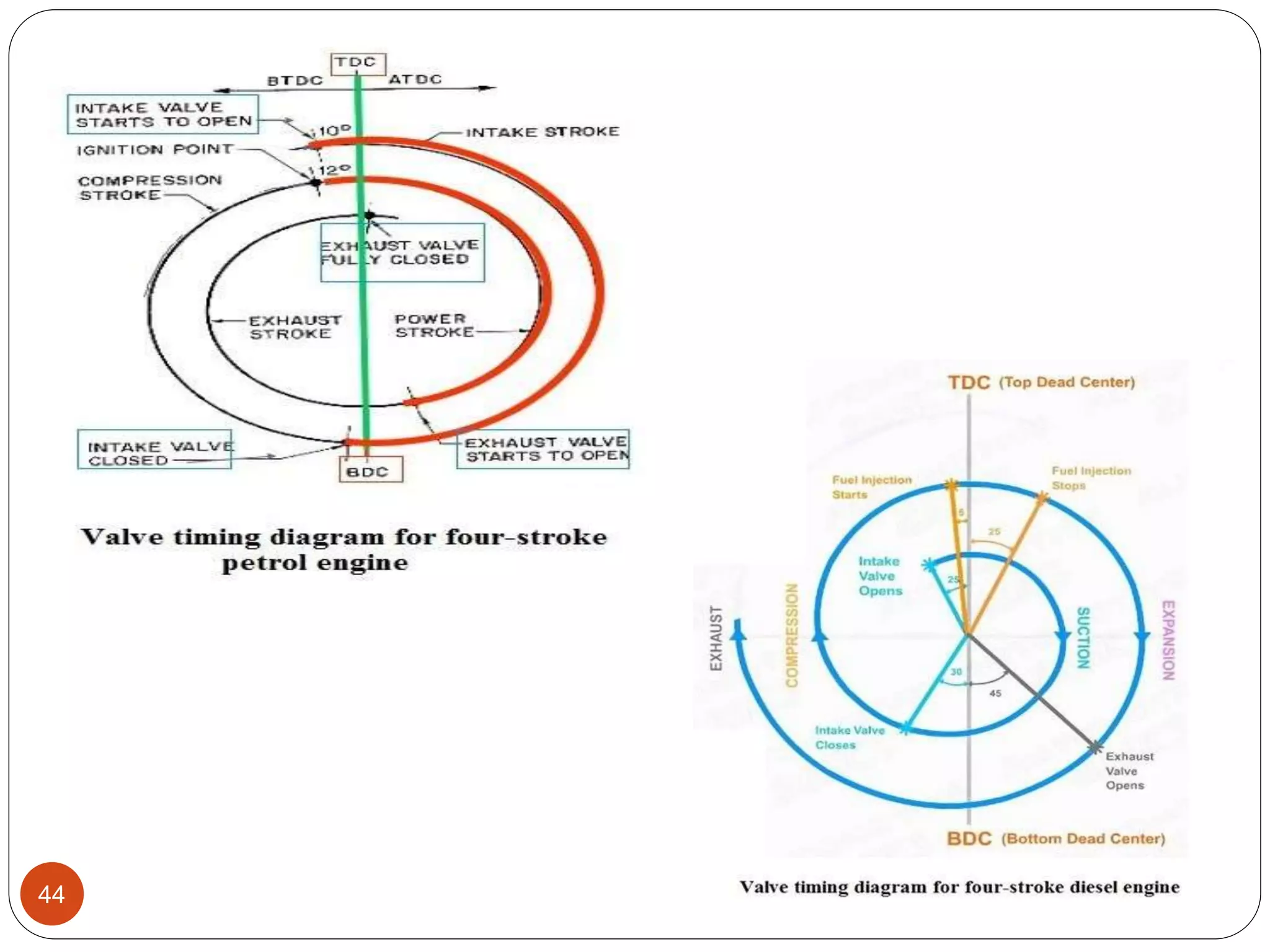

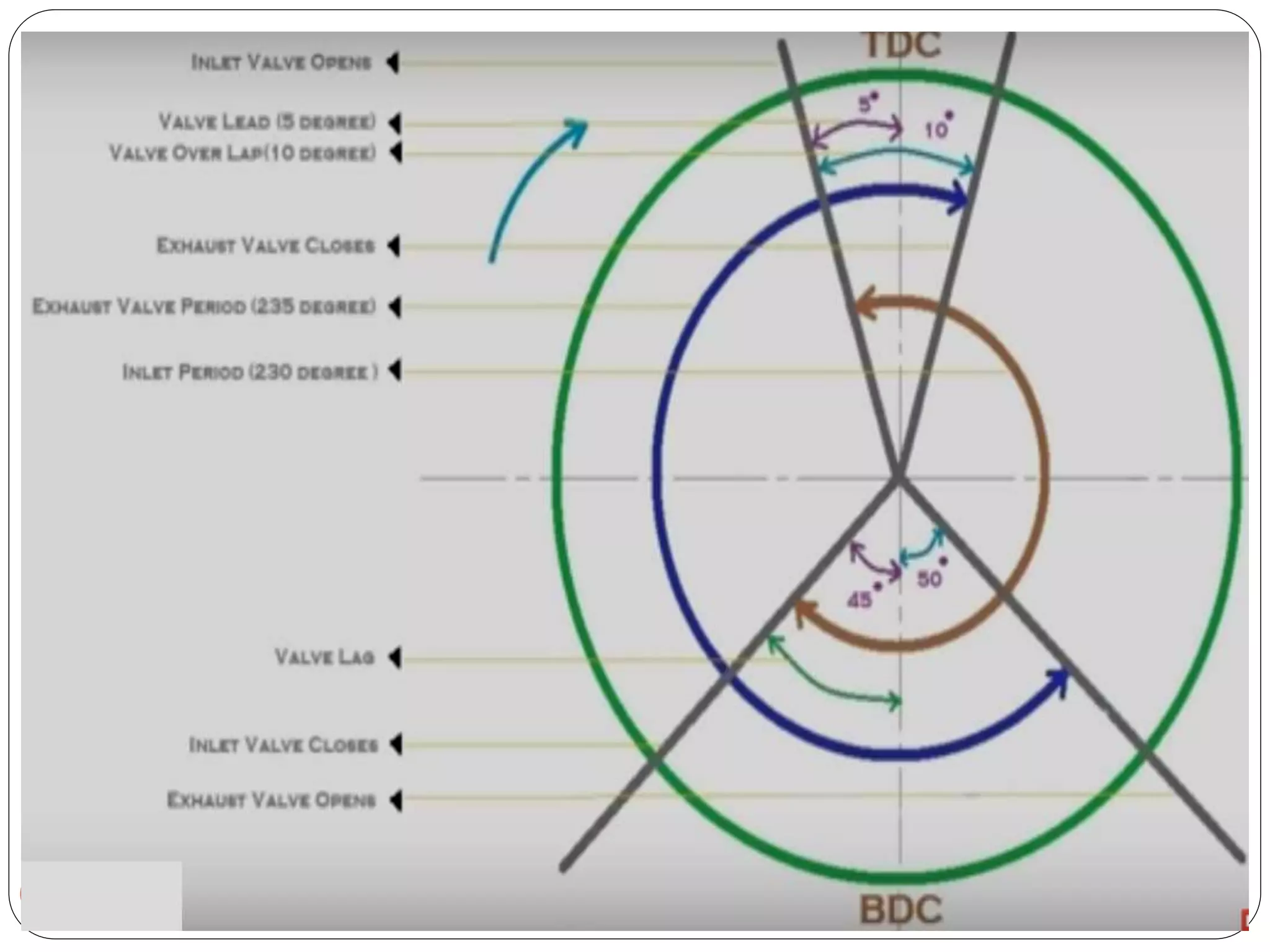

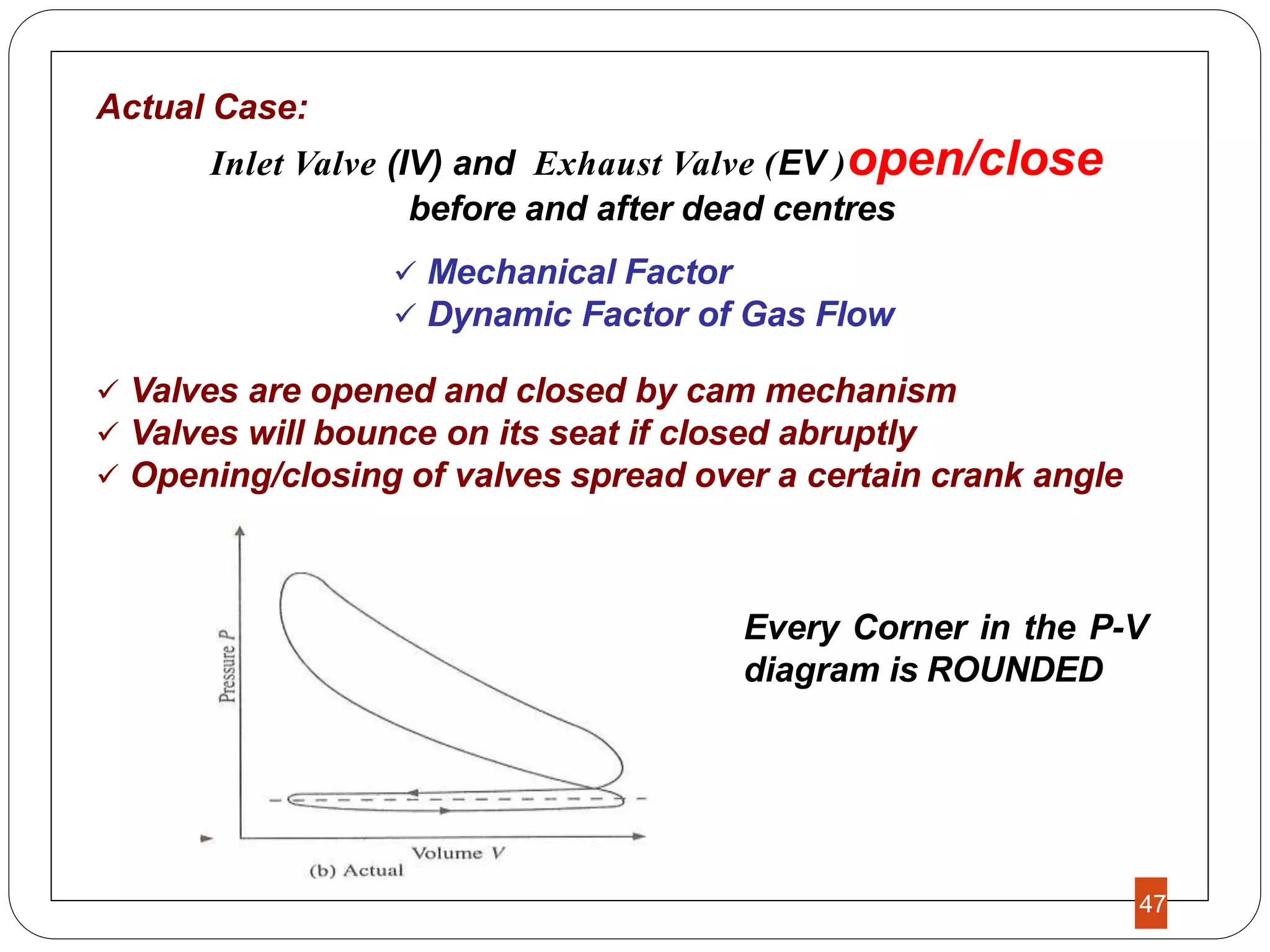

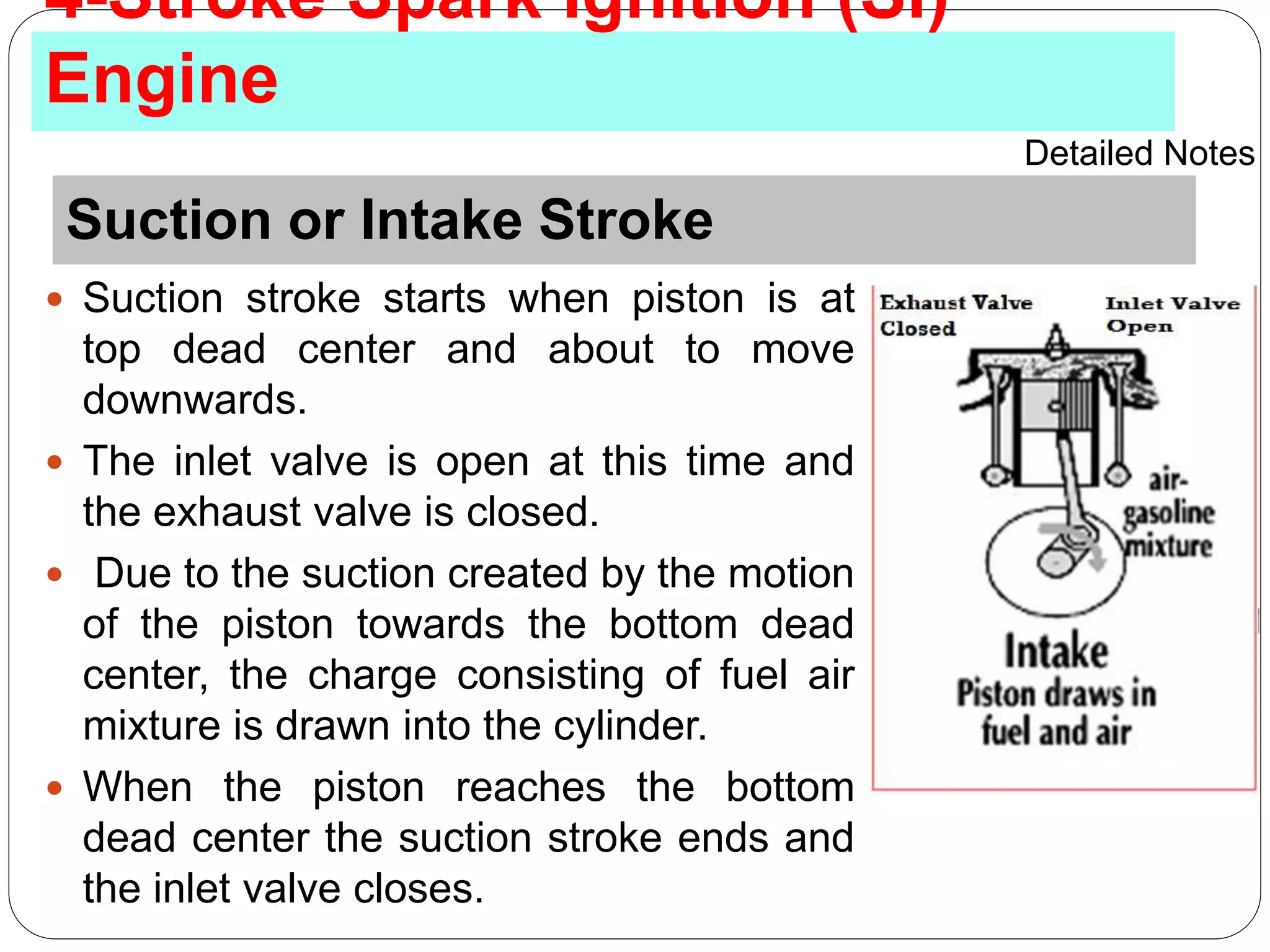

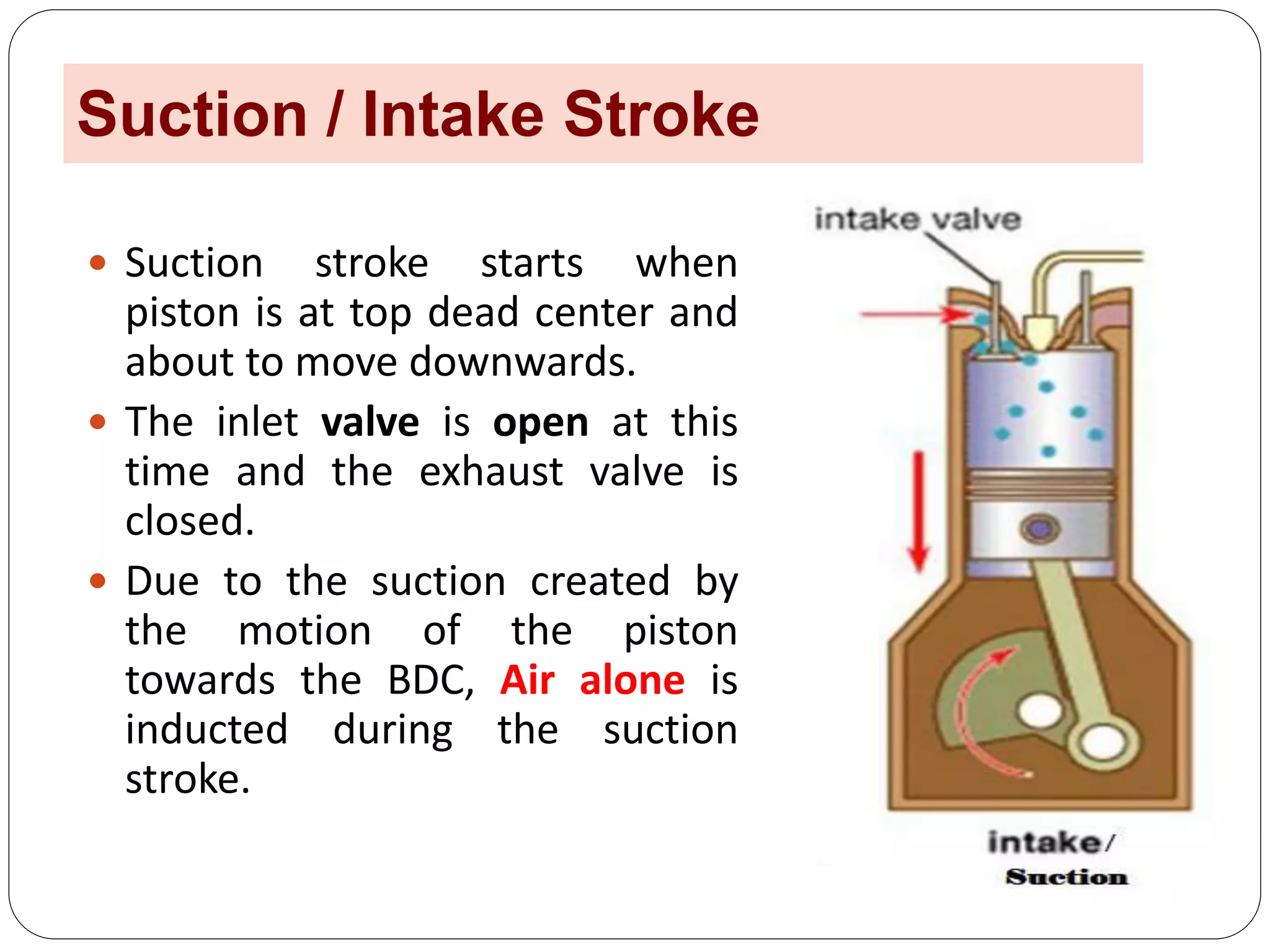

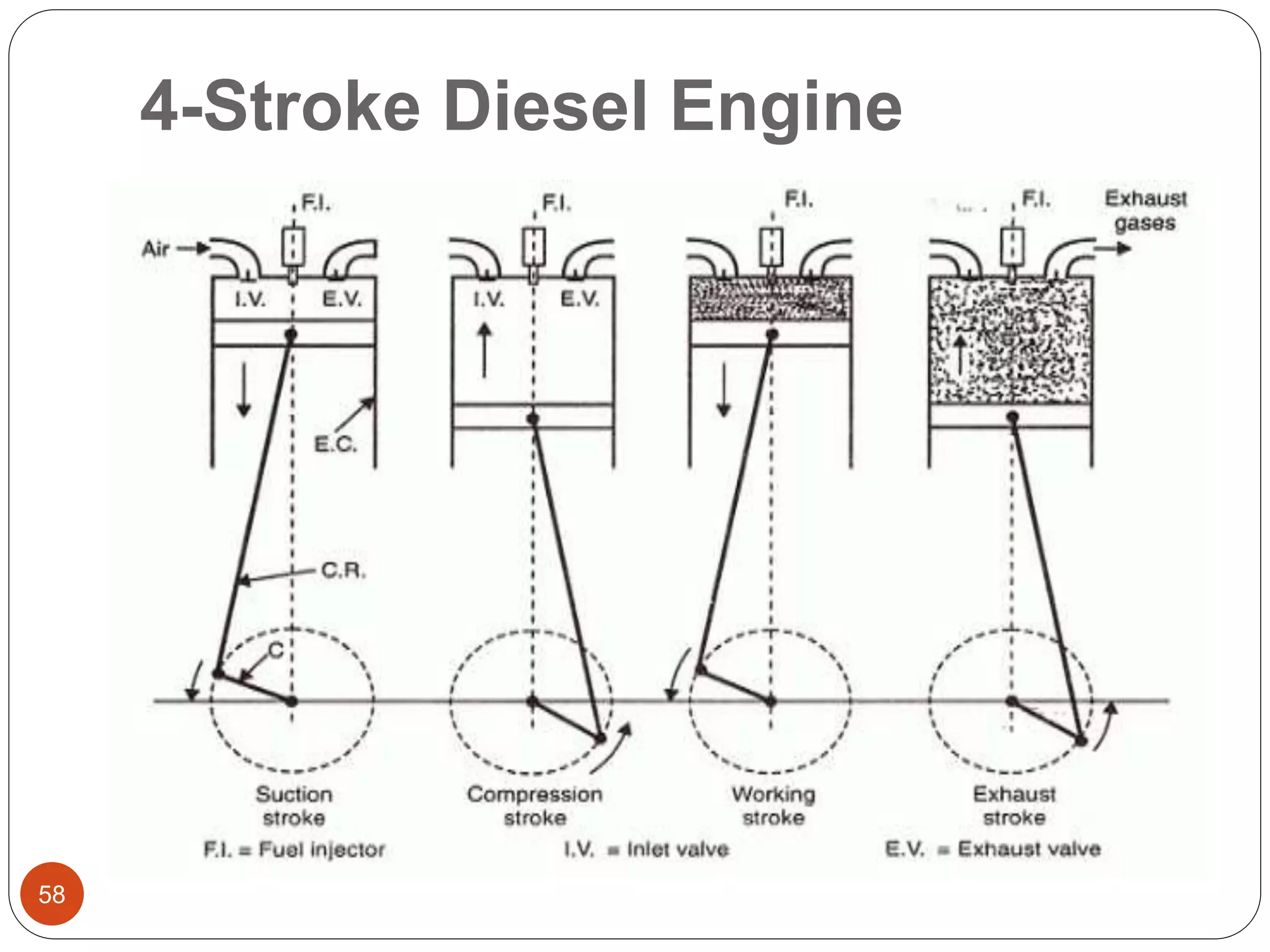

The document discusses the working principles of internal combustion engines. It begins by explaining that all IC engines must go through four strokes in a specific order: intake, compression, expansion/power, and exhaust. It then provides detailed descriptions and diagrams of how four-stroke petrol and diesel engines work through each stroke of the cycle. Key aspects covered include the valve timing, combustion processes, and thermodynamic cycles involved. Comparisons are made between two-stroke and four-stroke engines as well.