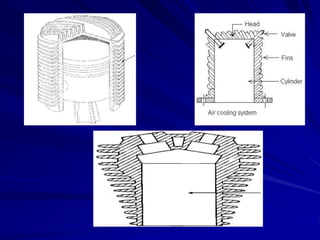

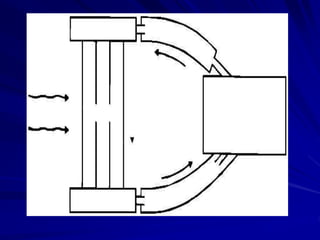

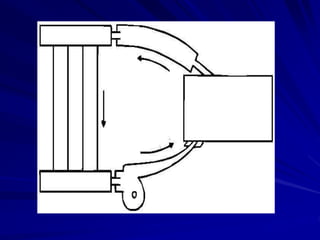

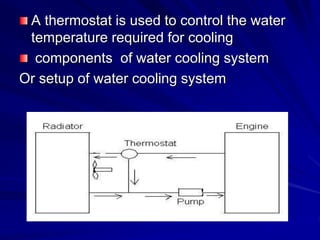

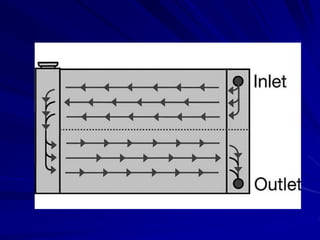

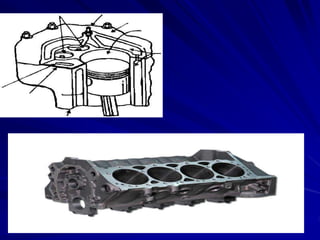

The document discusses cooling systems for engines. It describes the need to keep engines at an efficient operating temperature to ensure proper combustion and mechanical reliability. It then covers the main types of cooling systems - air cooling and water cooling. Air cooling uses fins on the engine to dissipate heat to air flowing over them, while water cooling circulates water through the engine using a pump, radiator, thermostat and water jackets to absorb heat and cool the water before recirculating it. The document provides details on how different water cooling systems work and their key components.