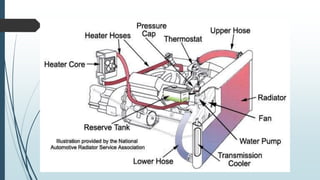

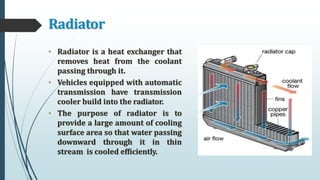

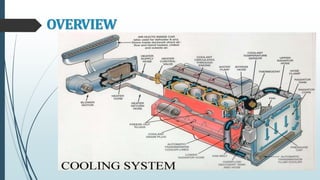

Ramasharya Pal submitted a summer training report on automotive cooling systems to Amitkumar at the Mechanical Engineering department. The report discussed the different types of cooling systems including liquid, air, and oil cooling. It described the key components of liquid cooling systems like water jackets, water pumps, fans, thermostats and radiators. Air cooling systems use cooling fins and baffles to dissipate heat. Oil cooling transfers heat from the engine to the oil and then through an oil cooler. Maintaining optimal engine temperature is important for performance and preventing damage.