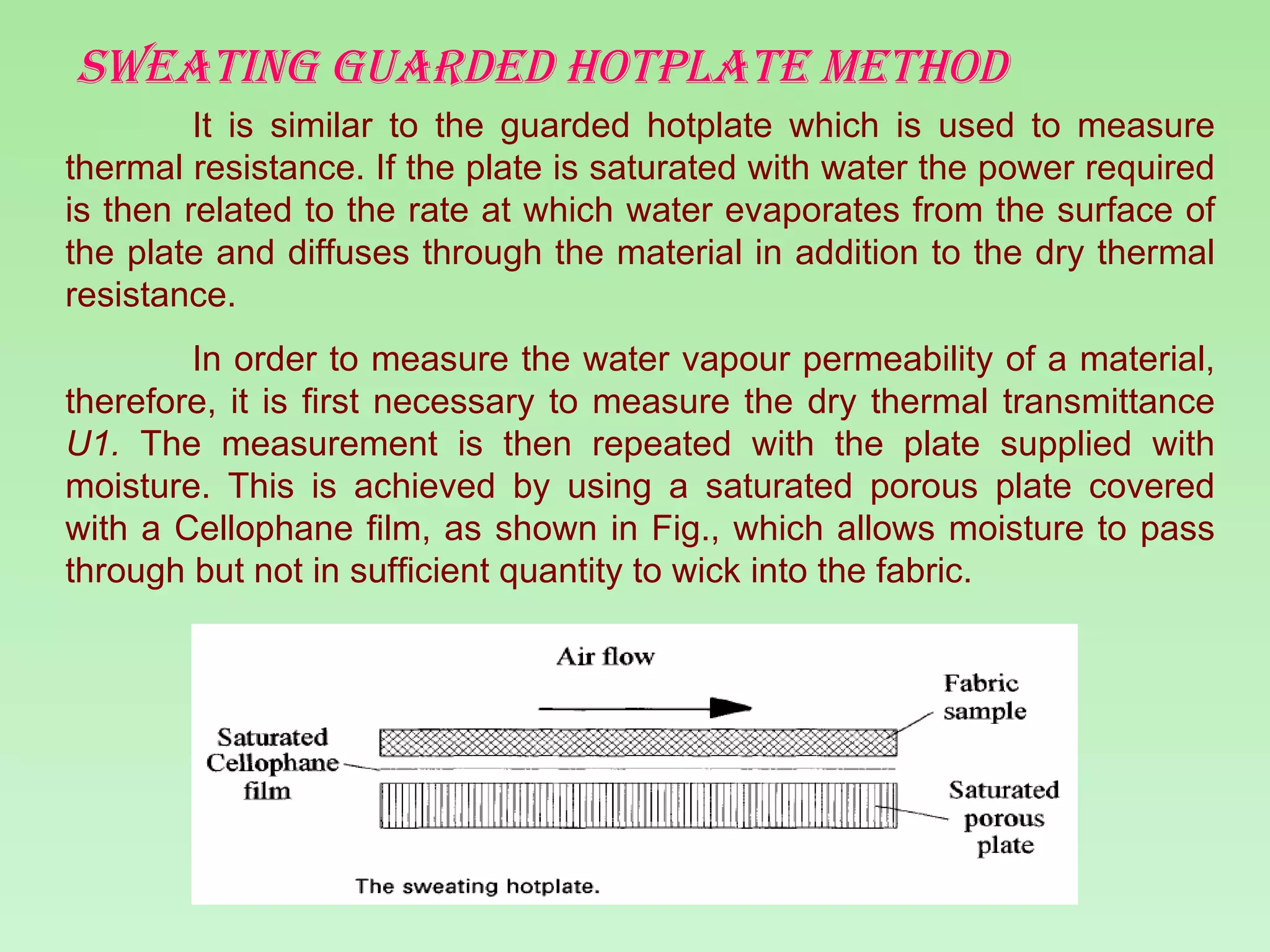

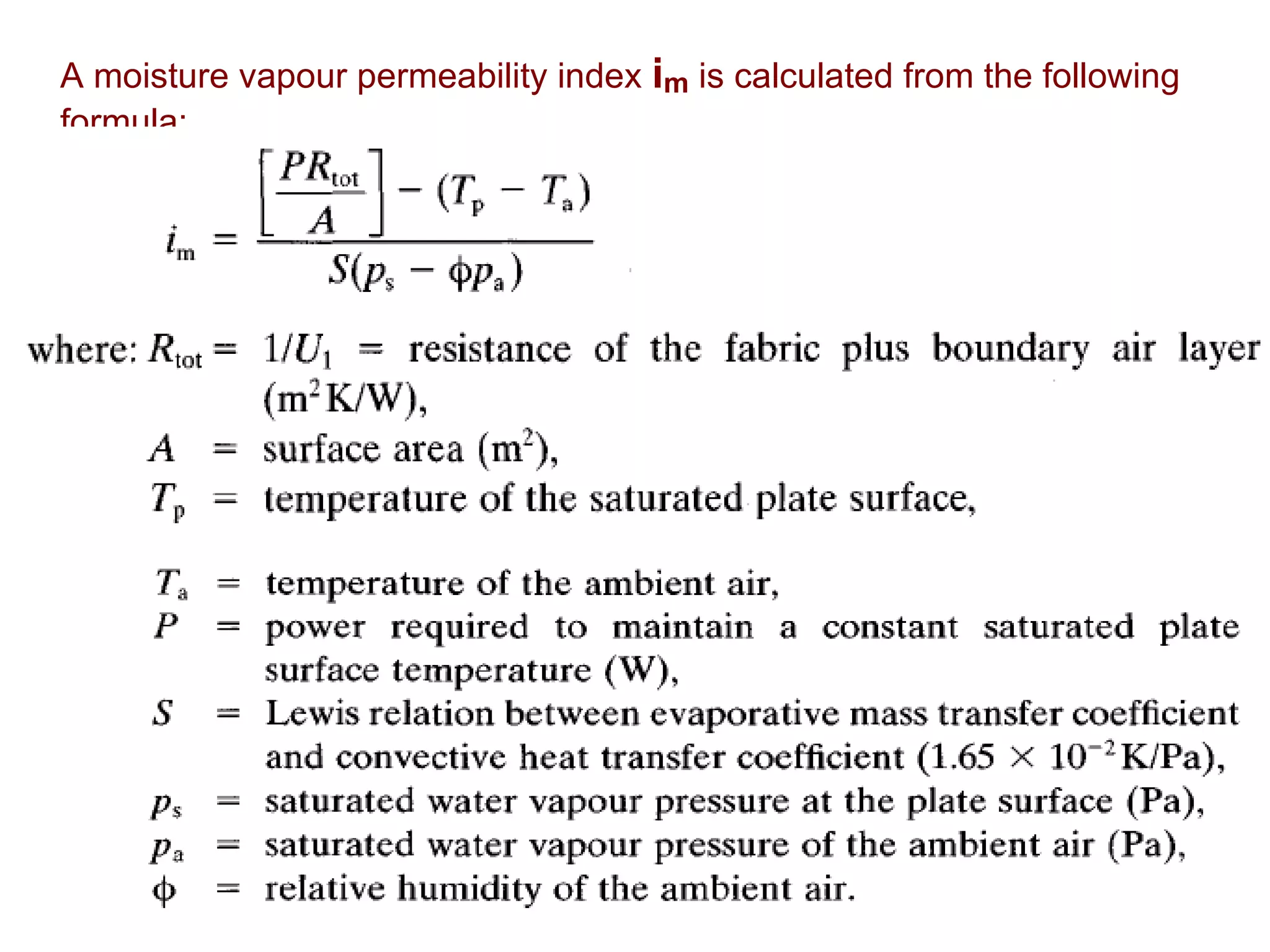

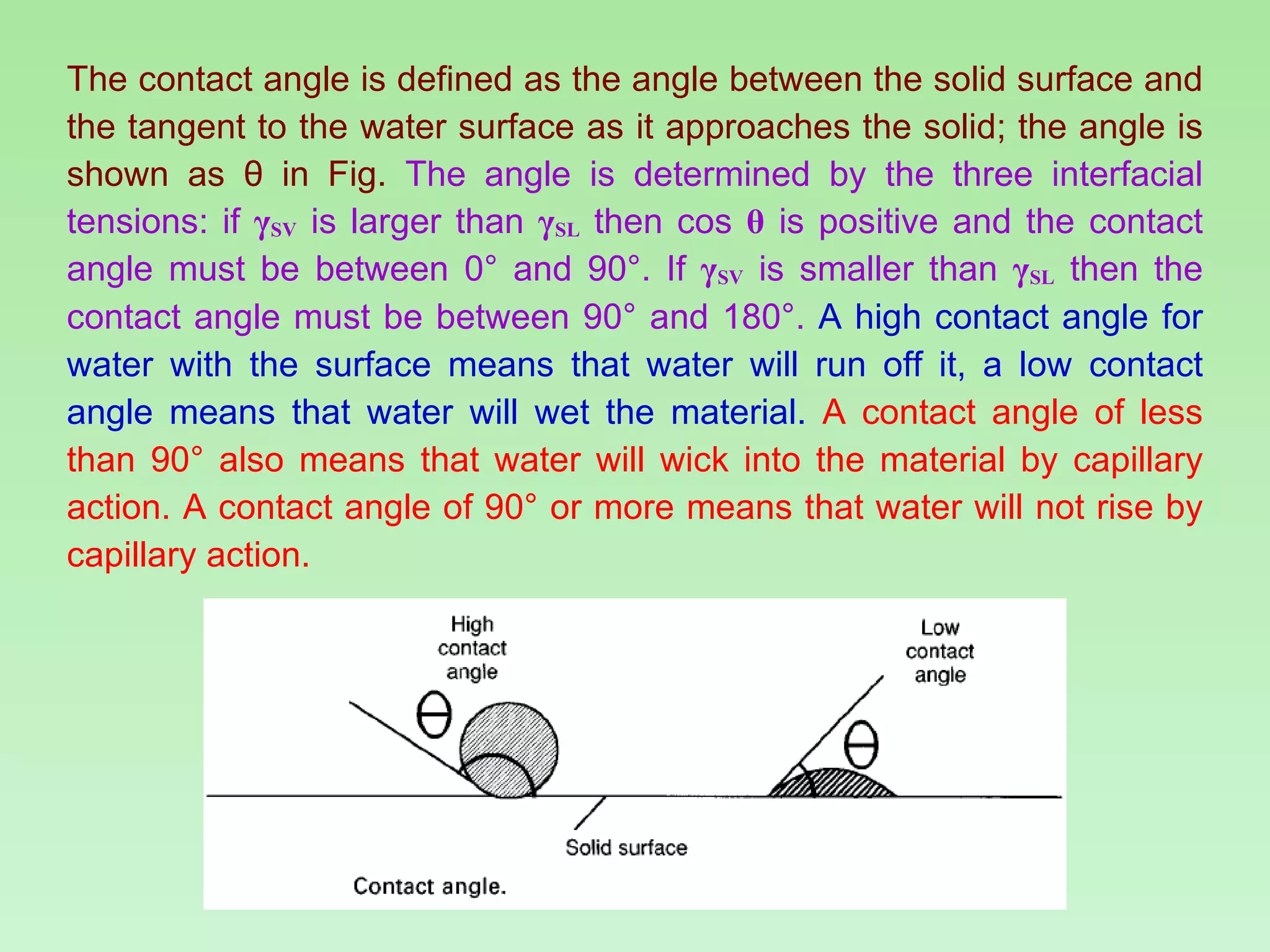

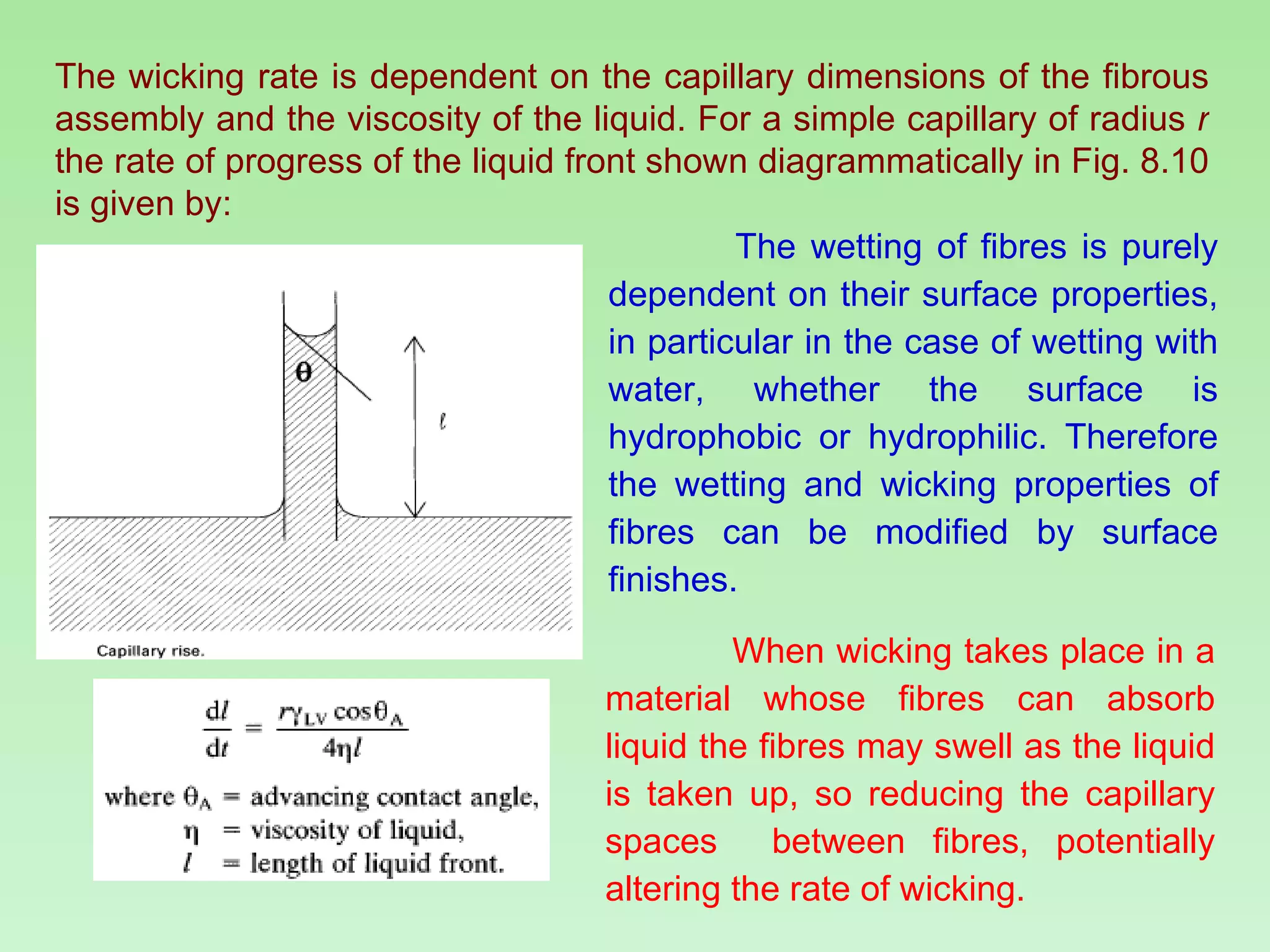

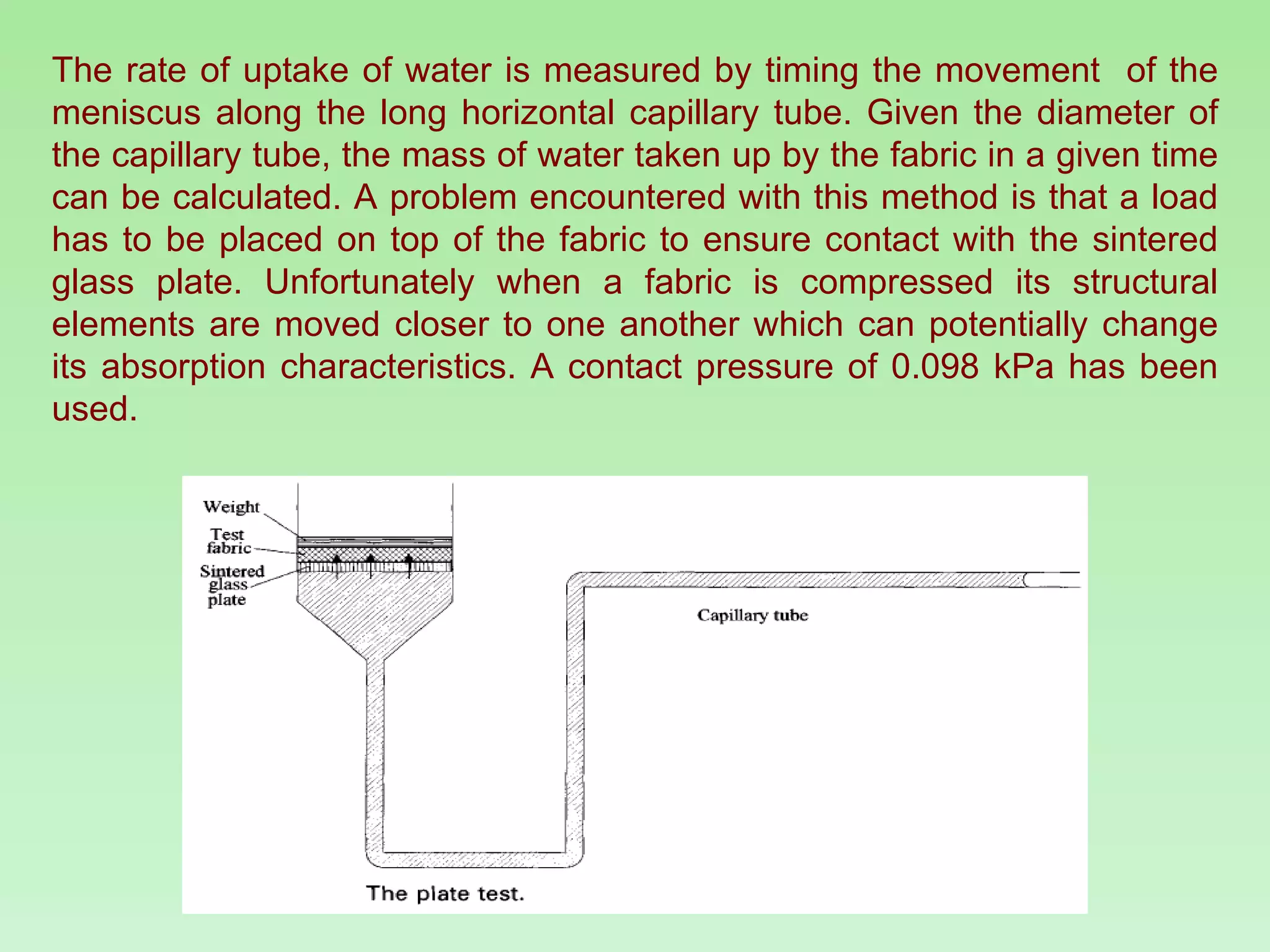

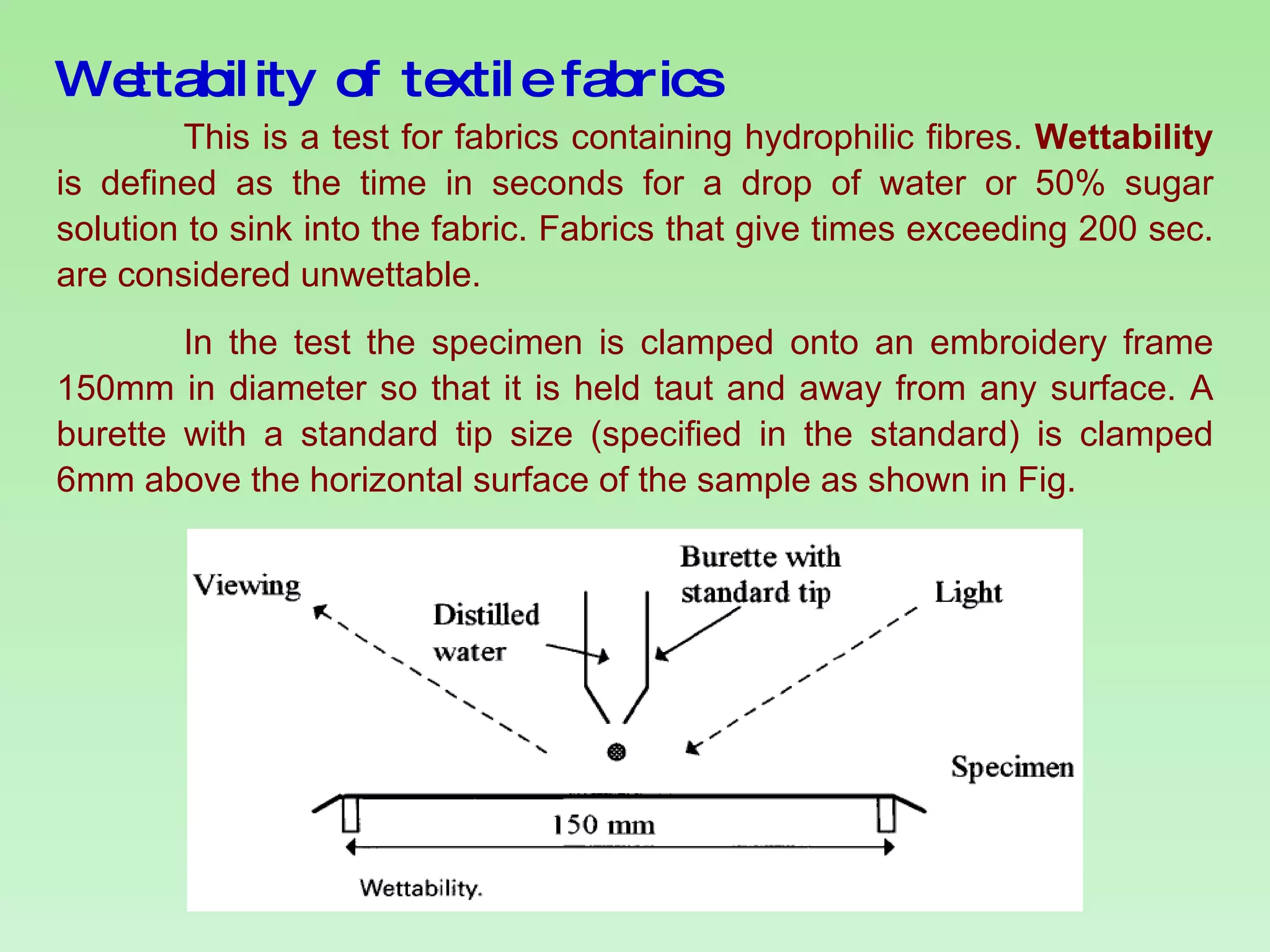

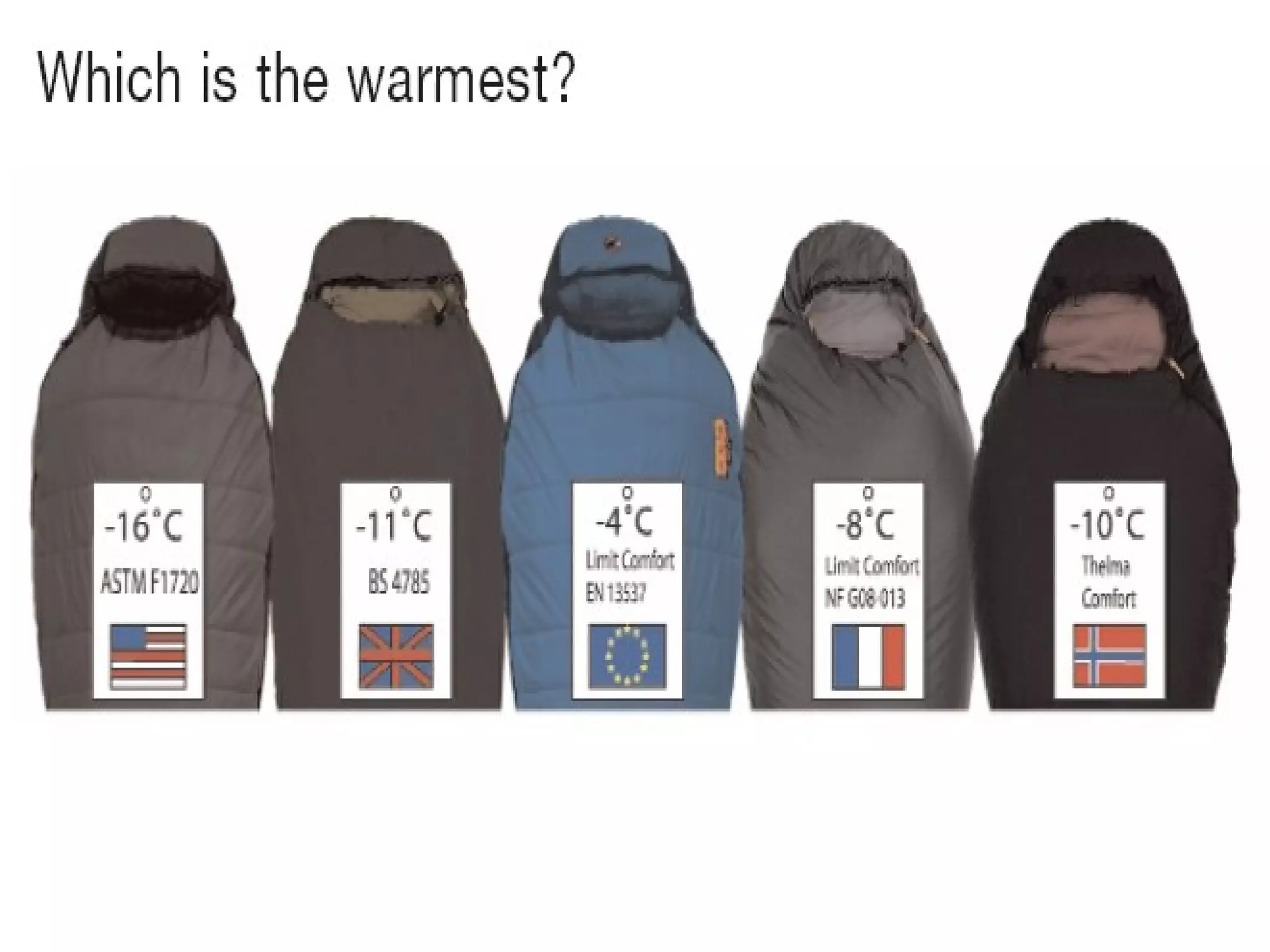

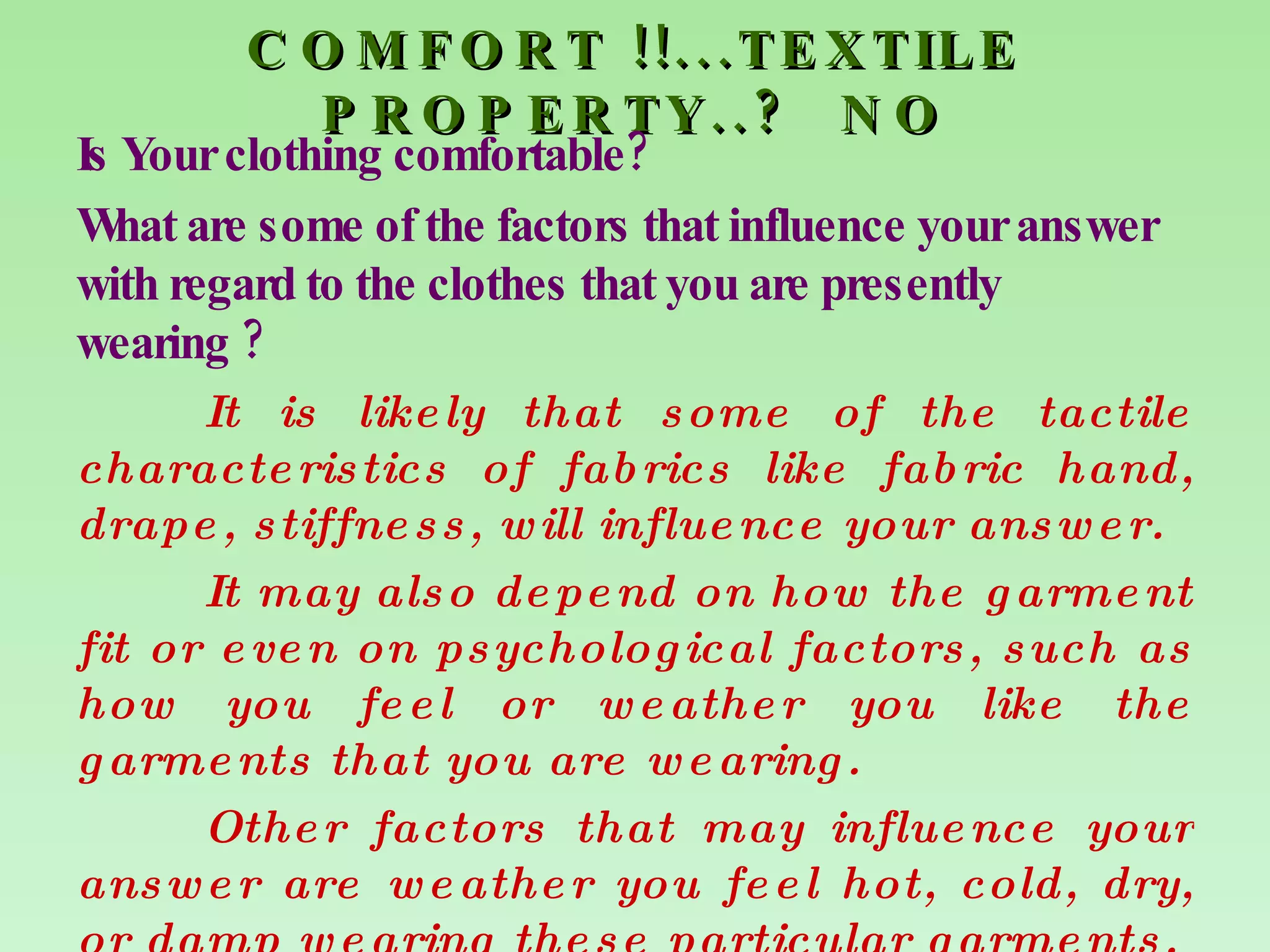

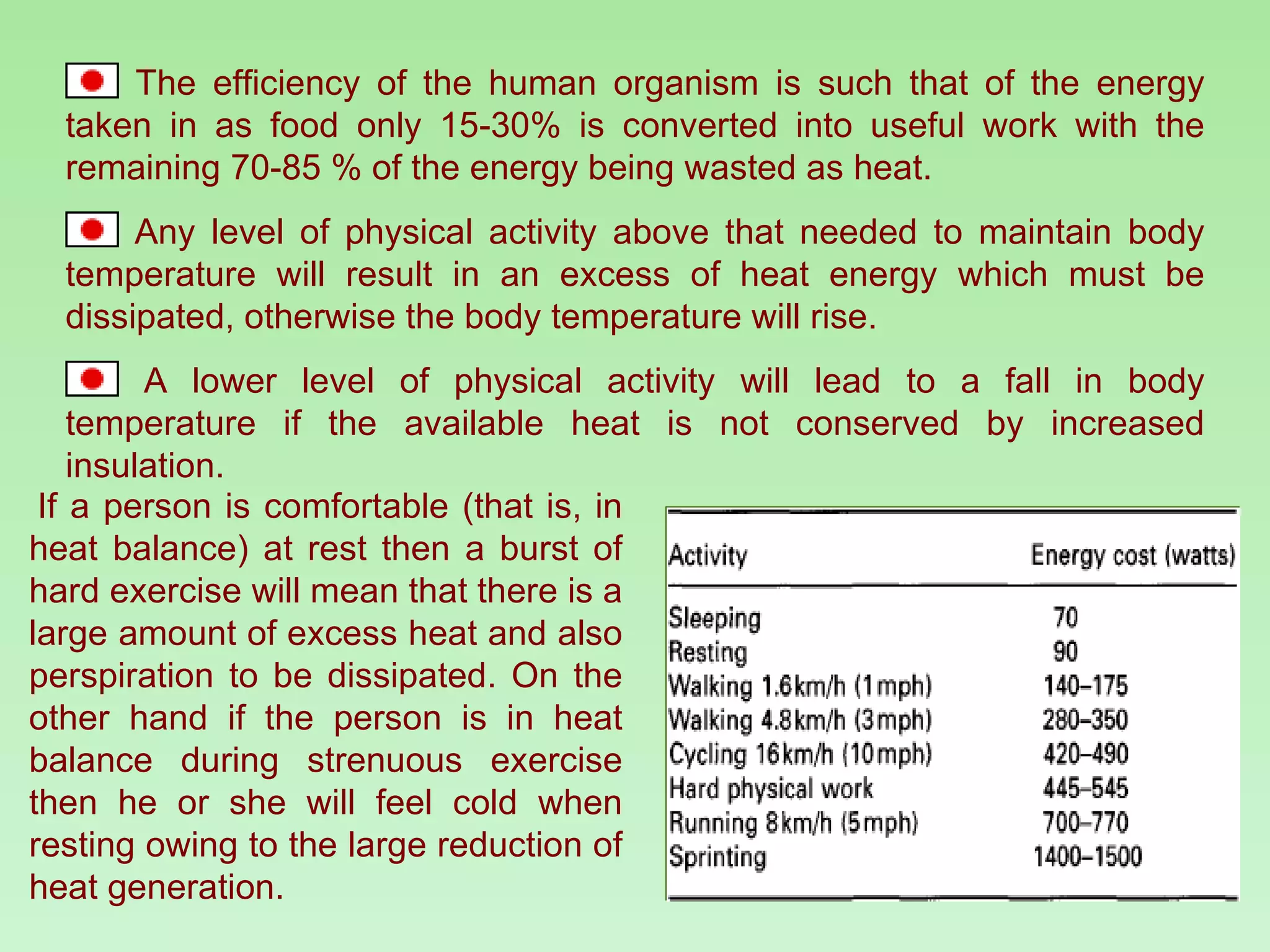

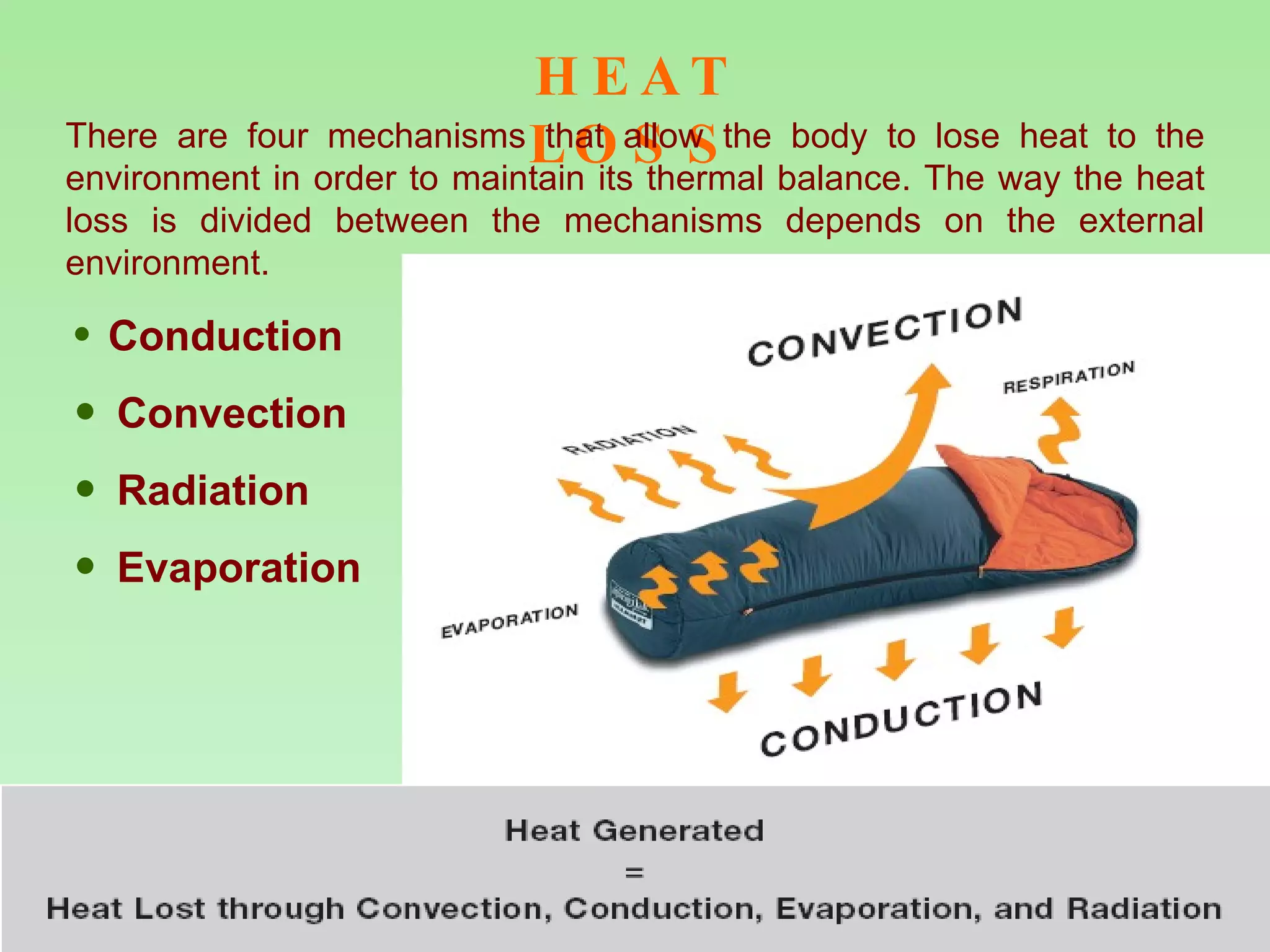

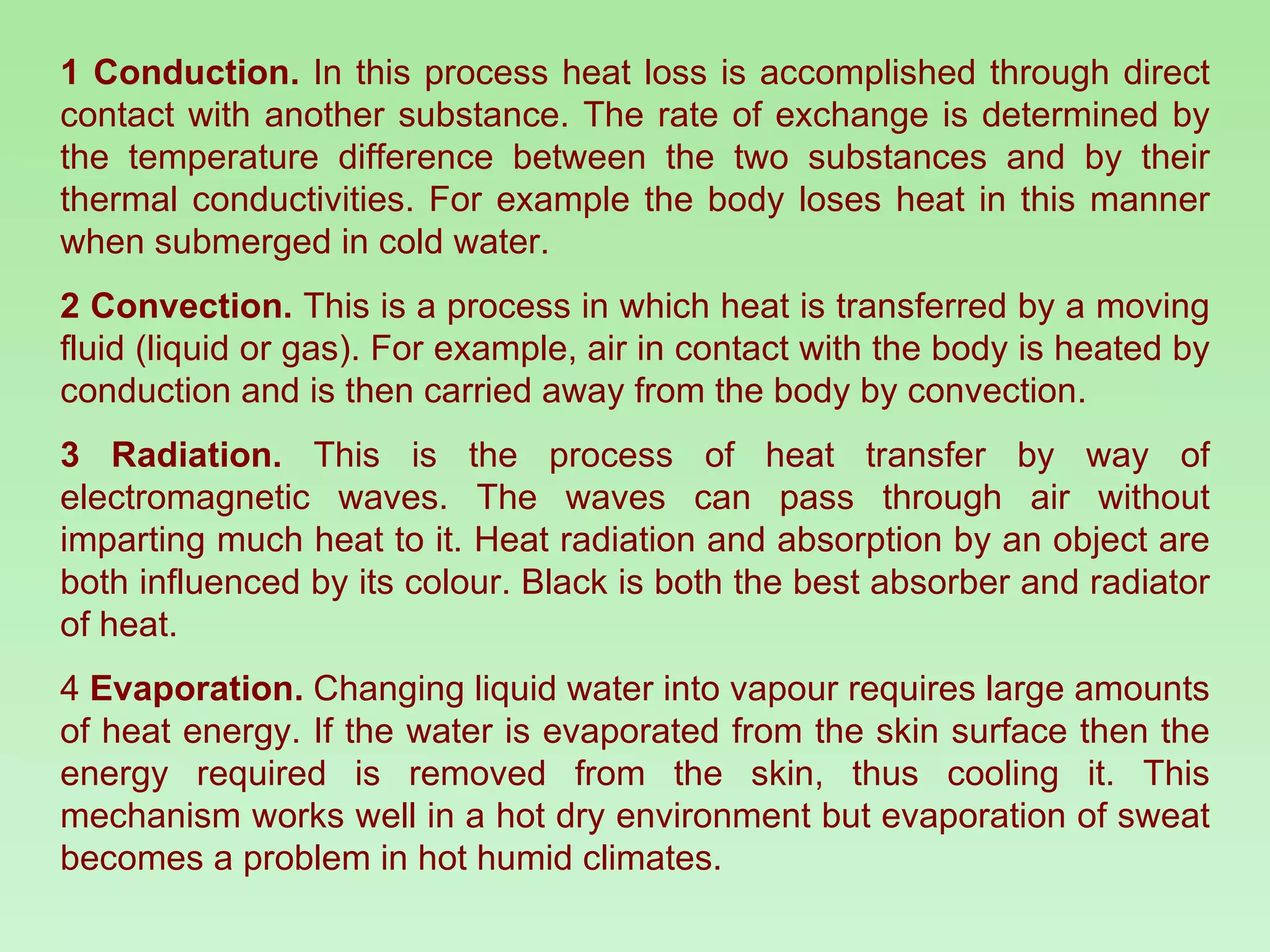

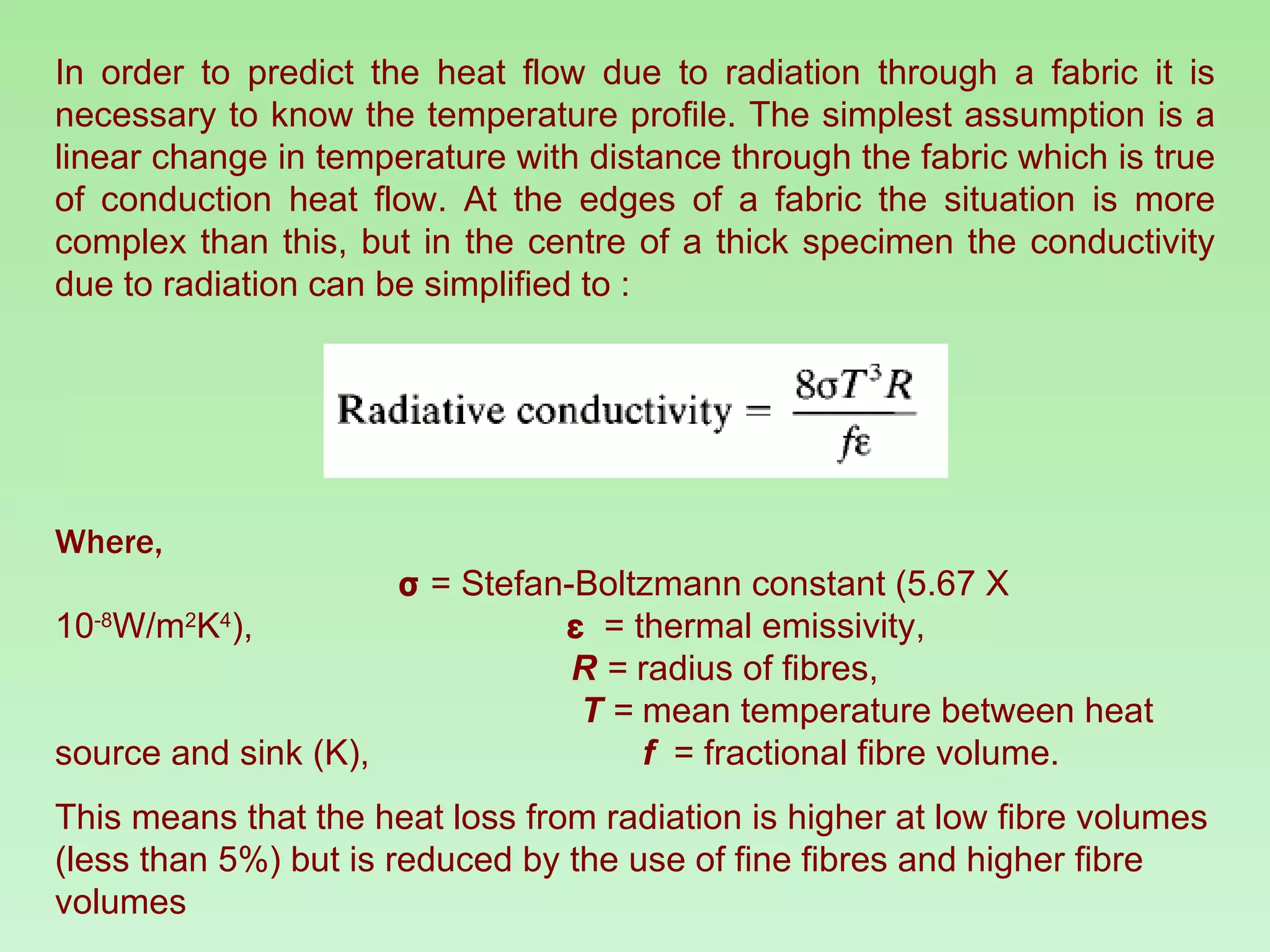

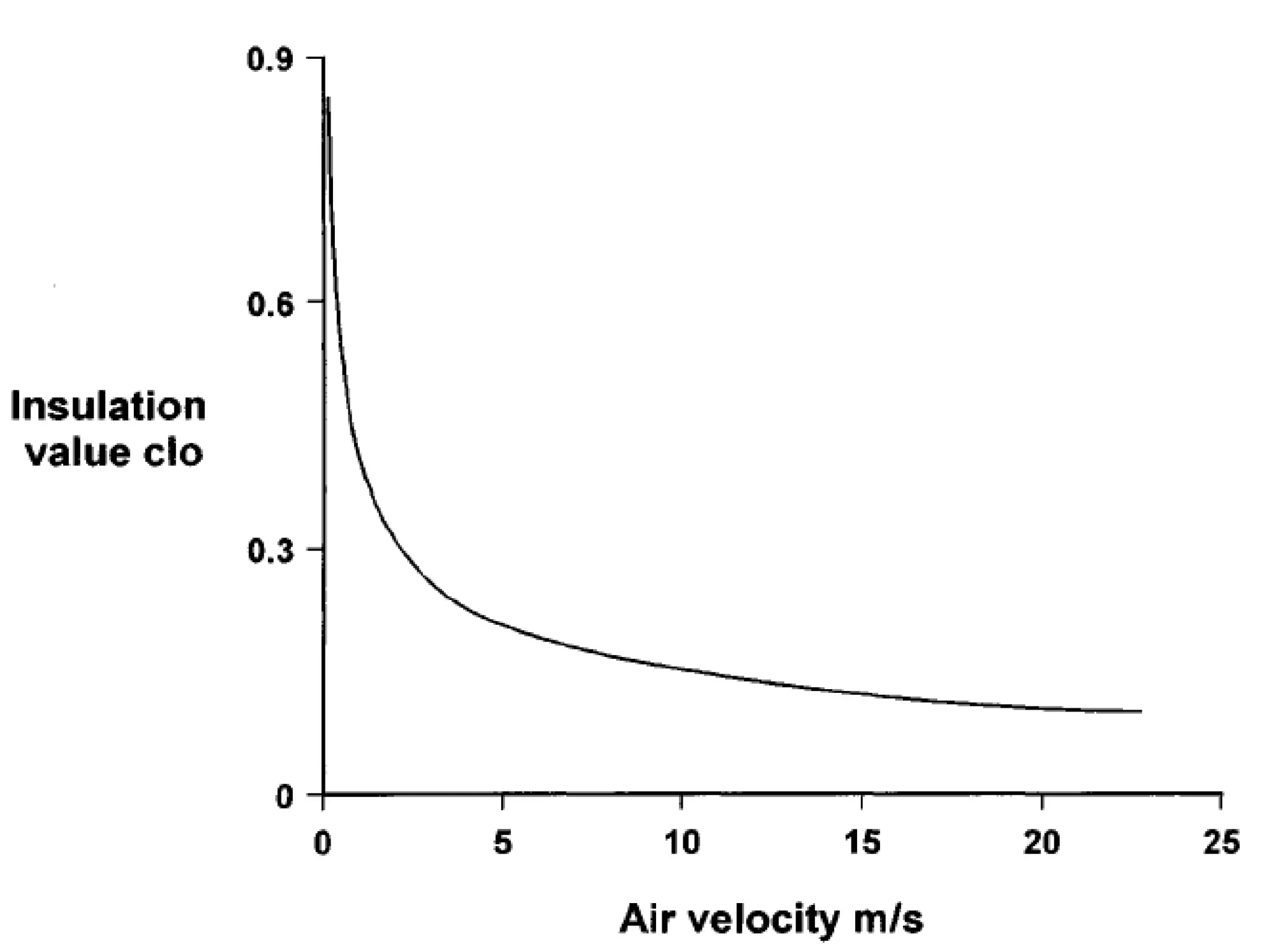

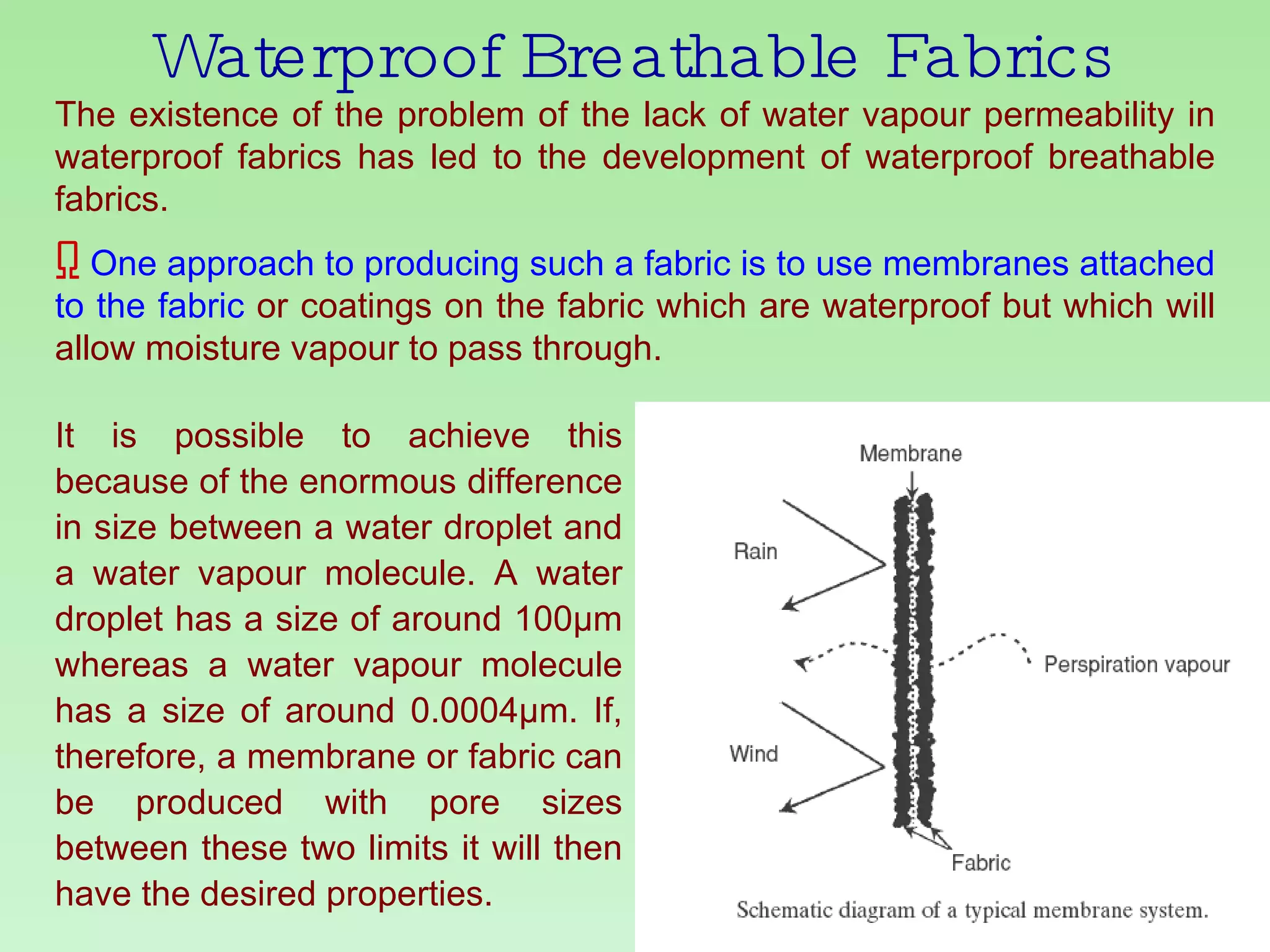

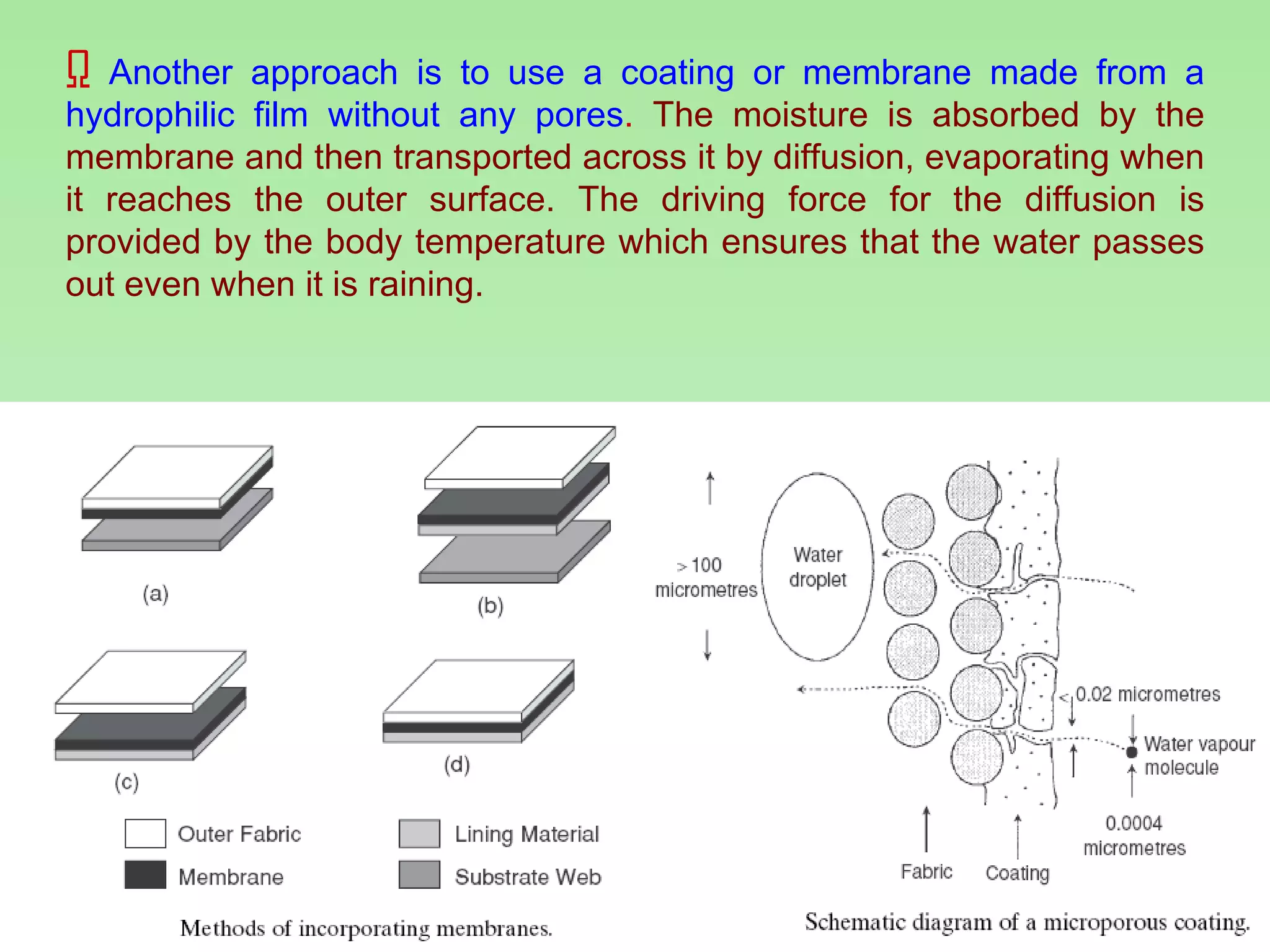

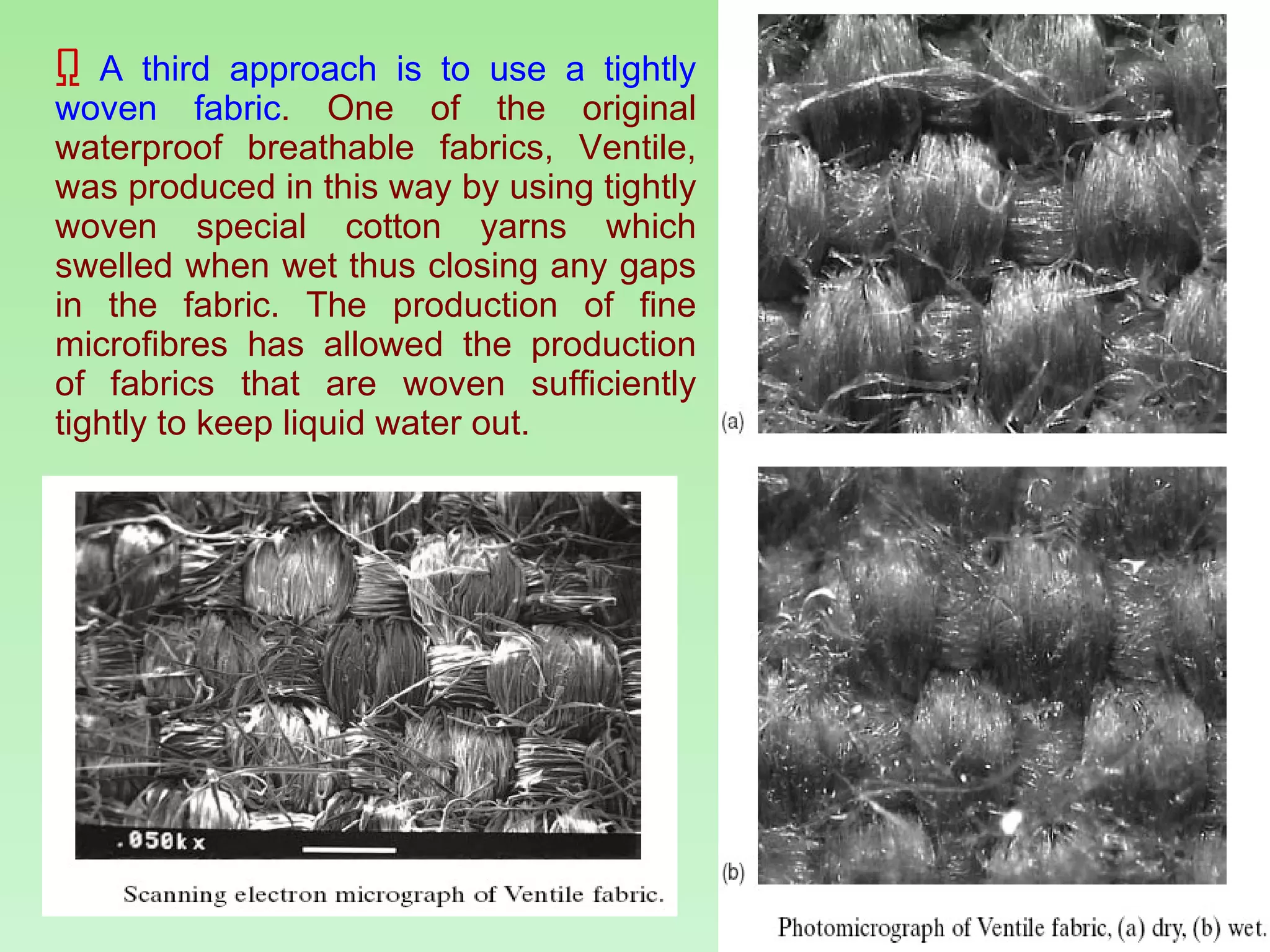

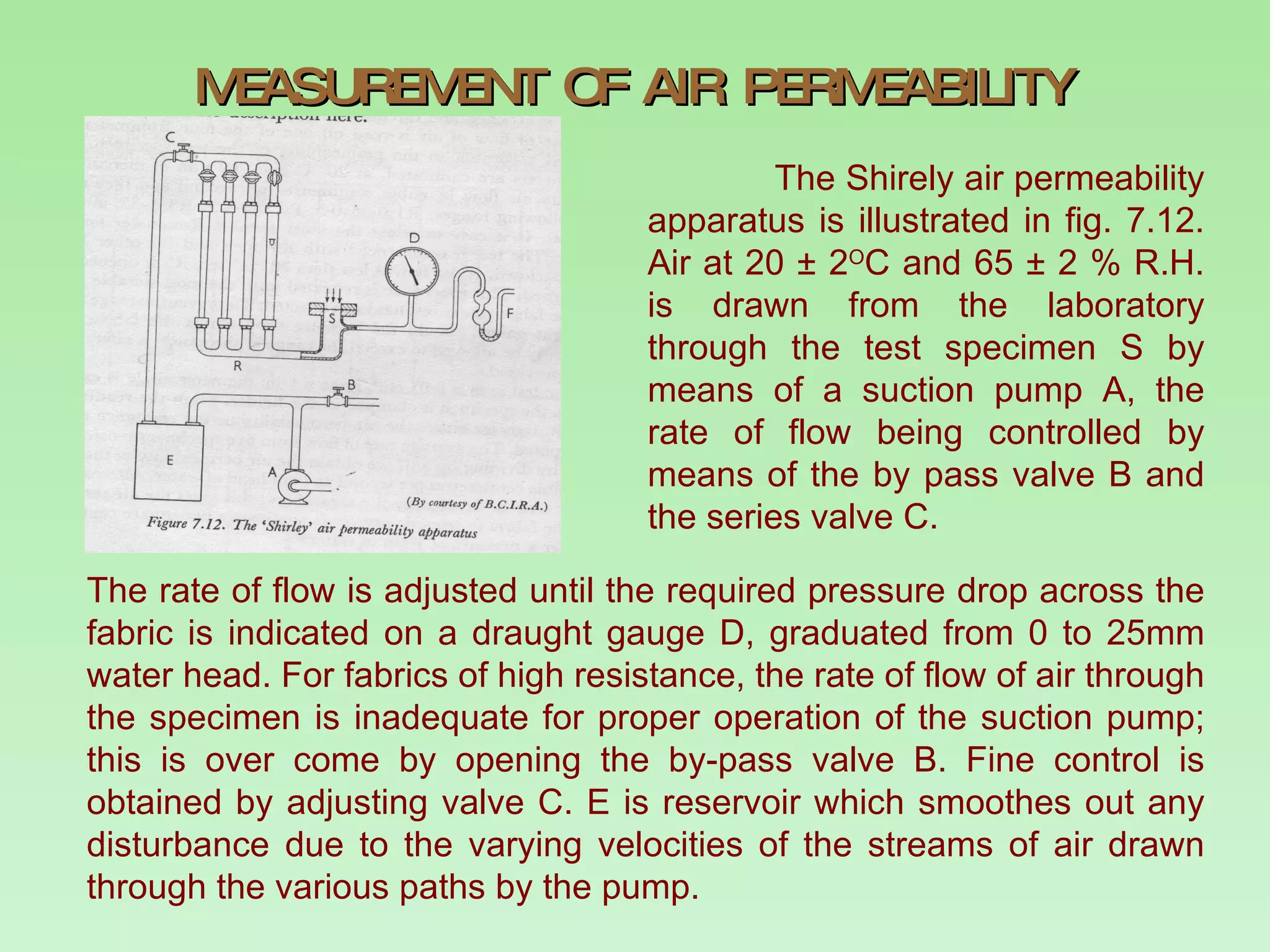

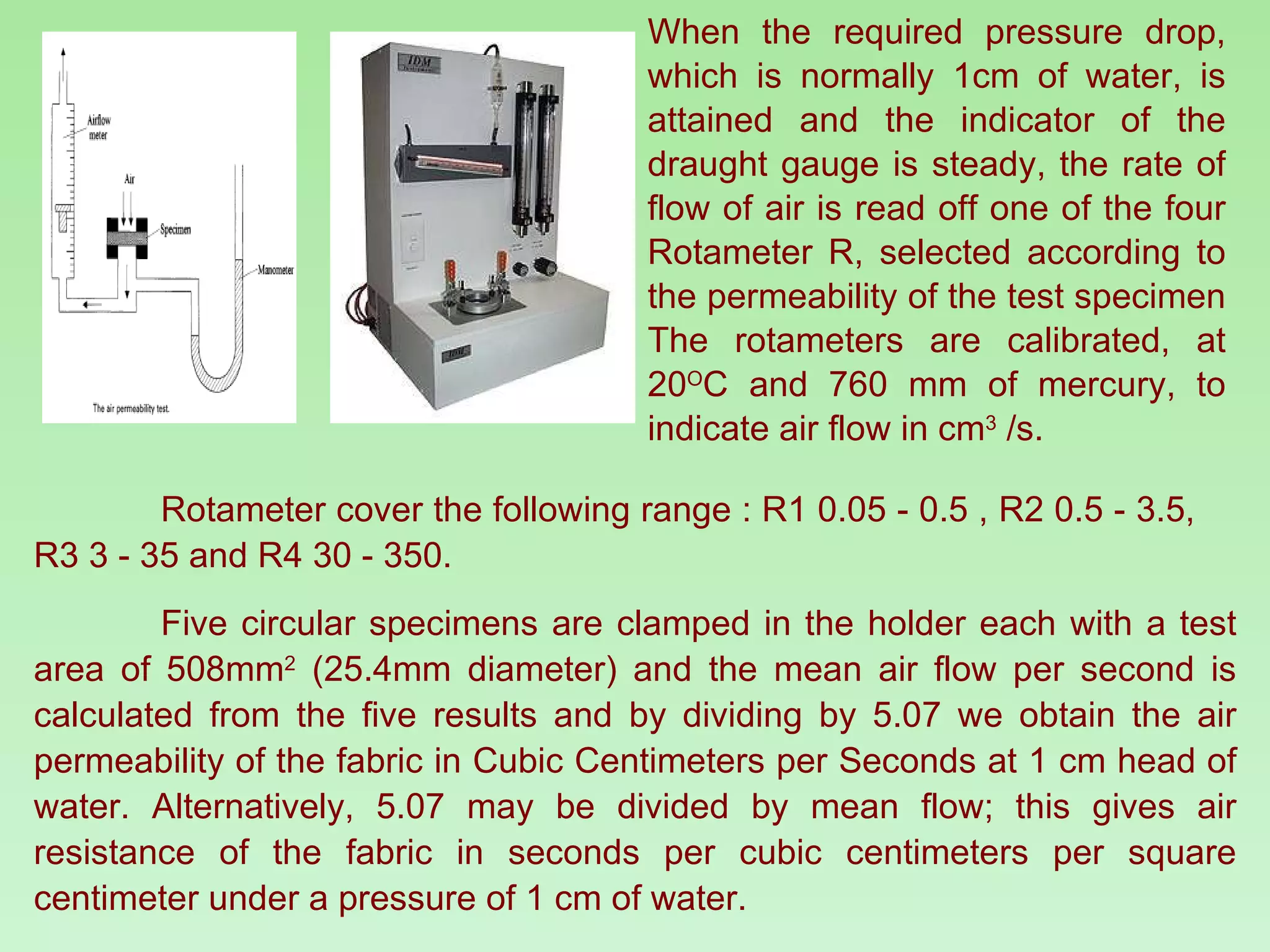

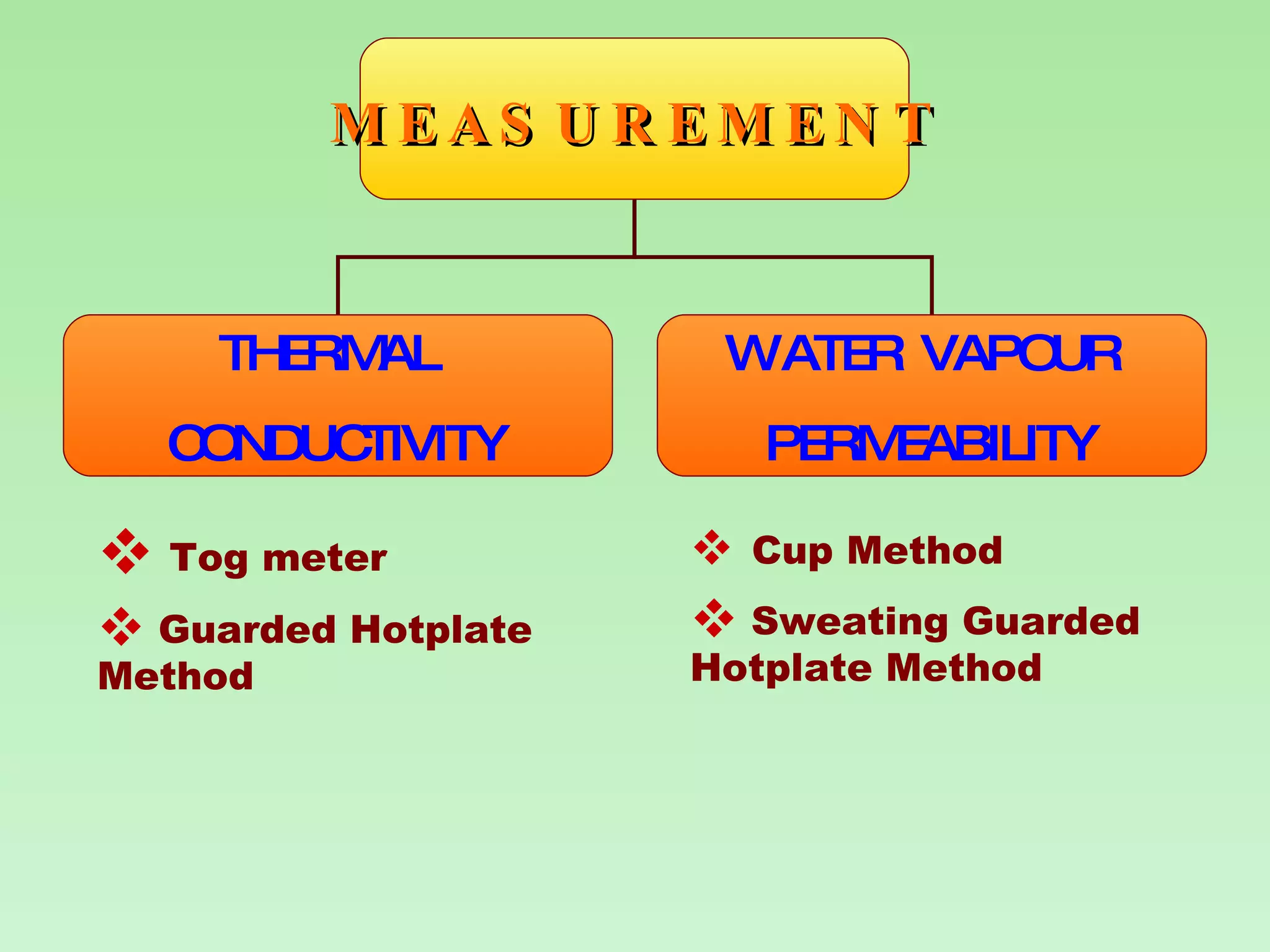

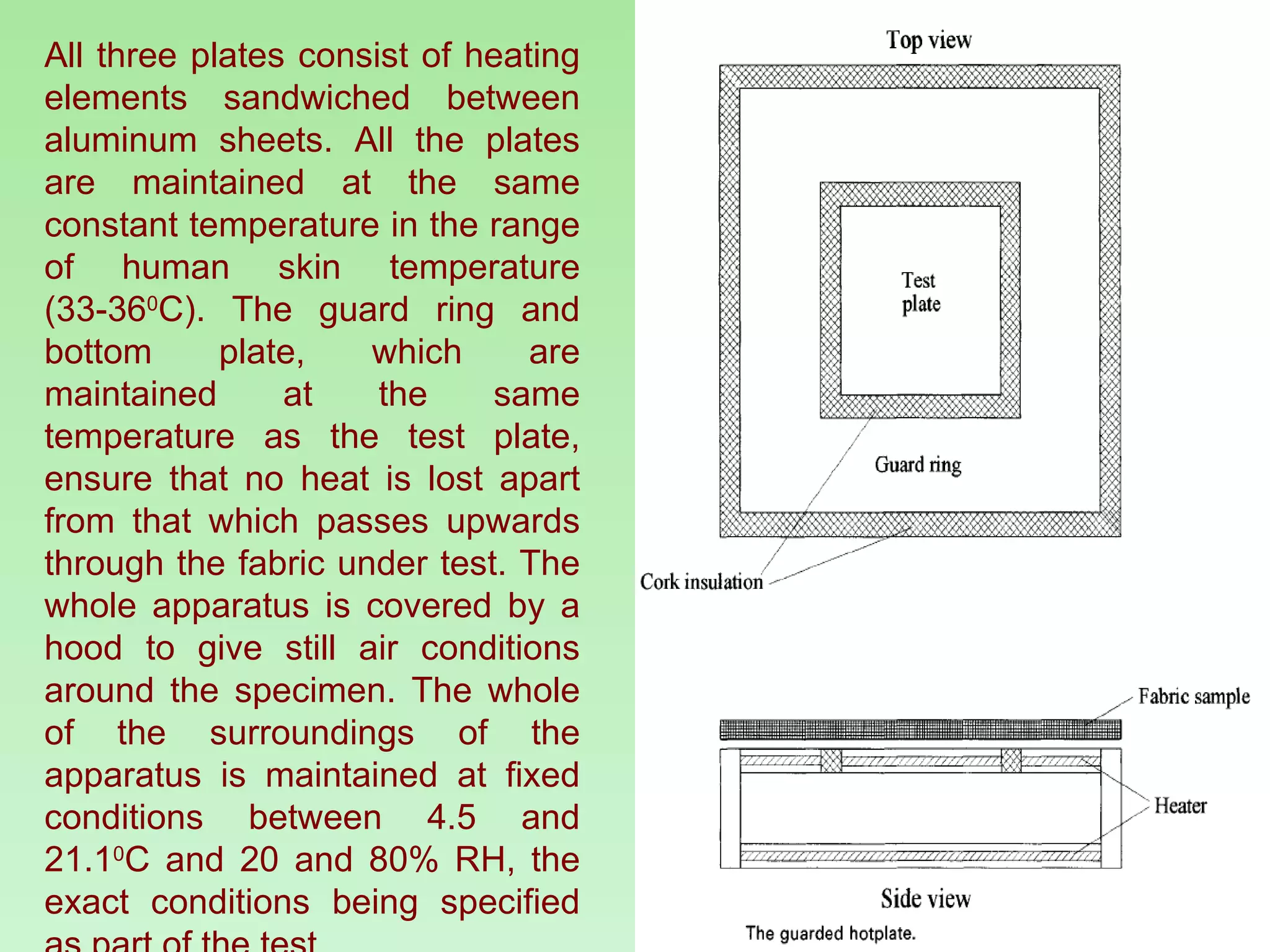

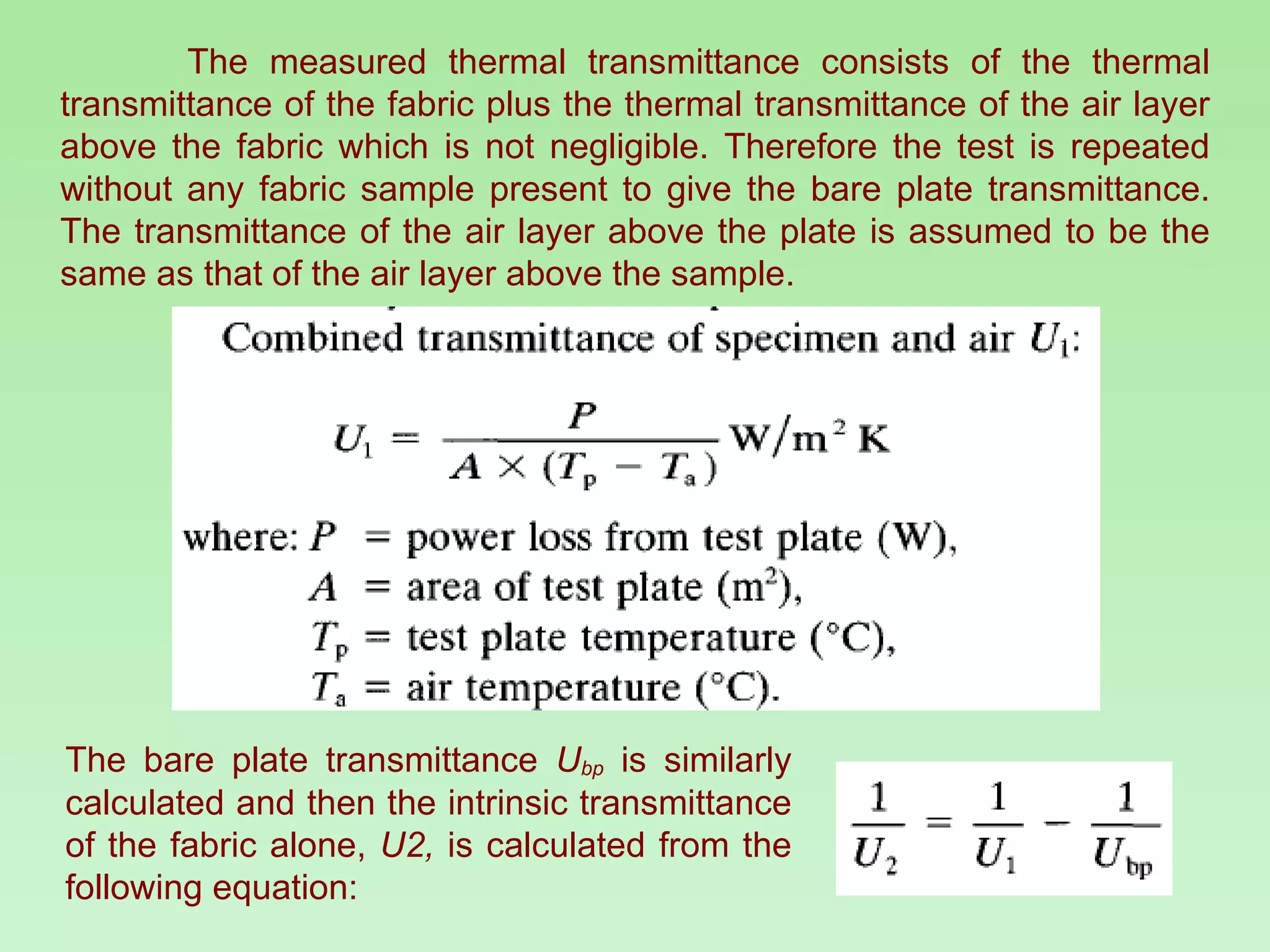

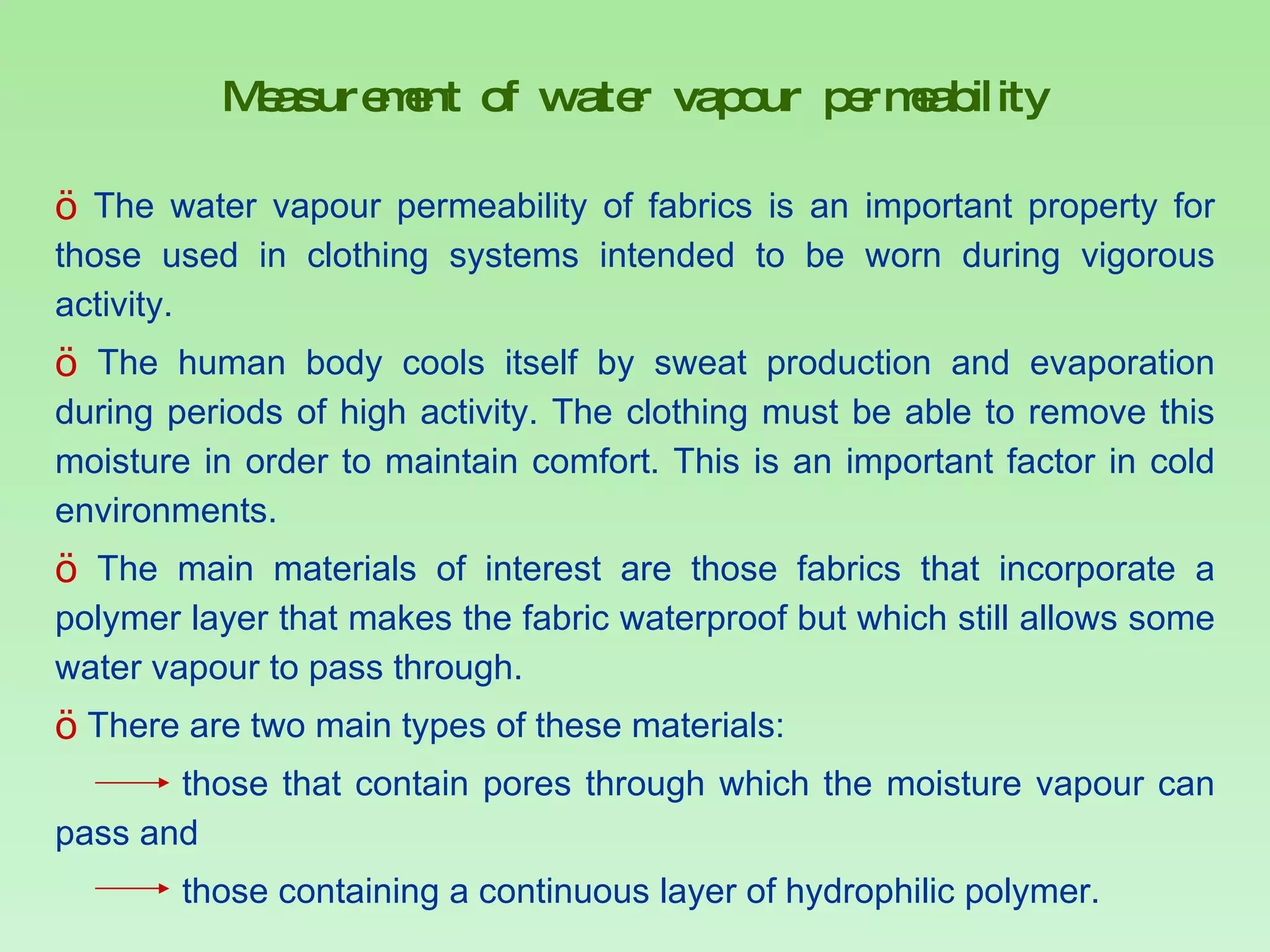

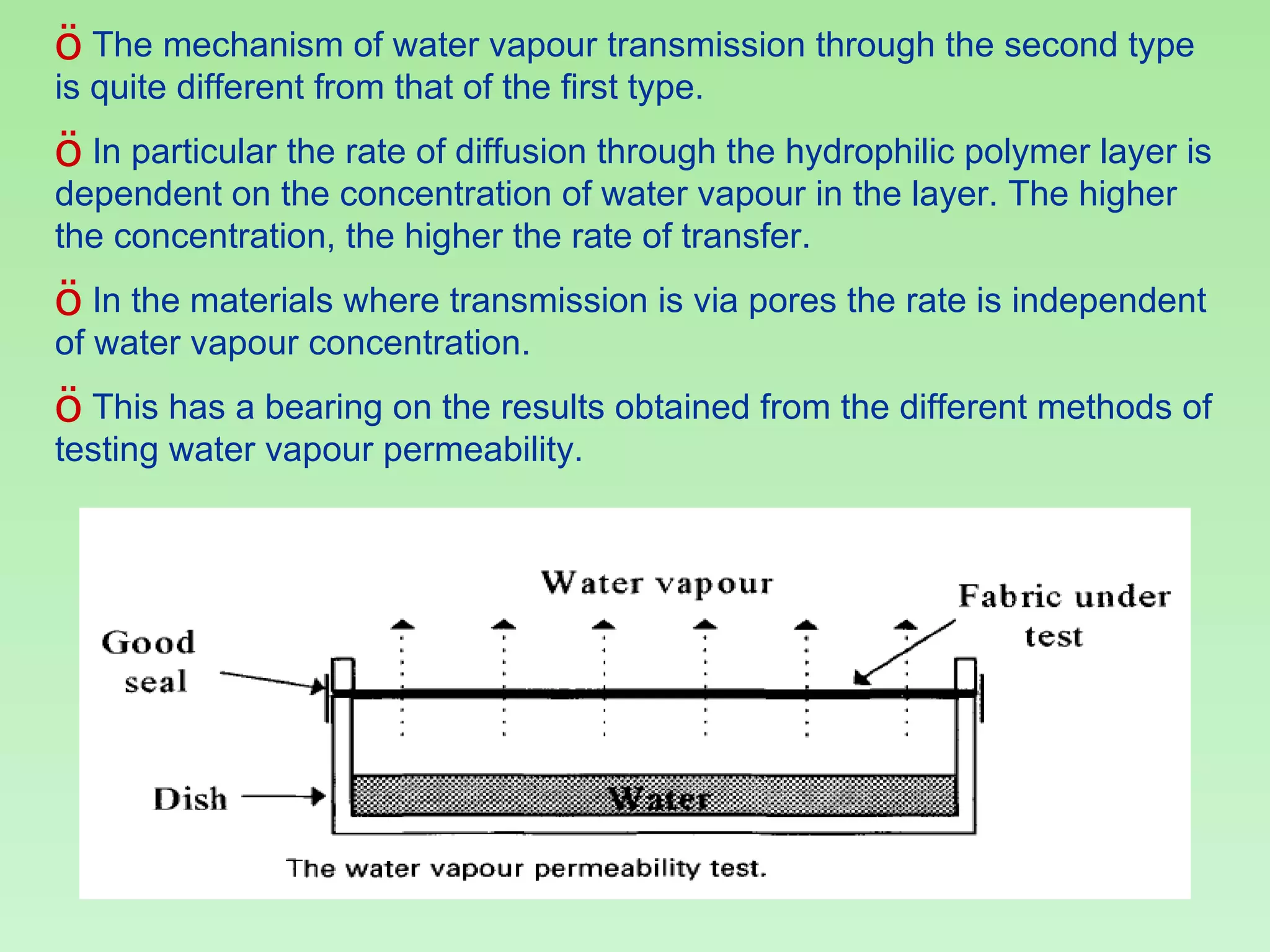

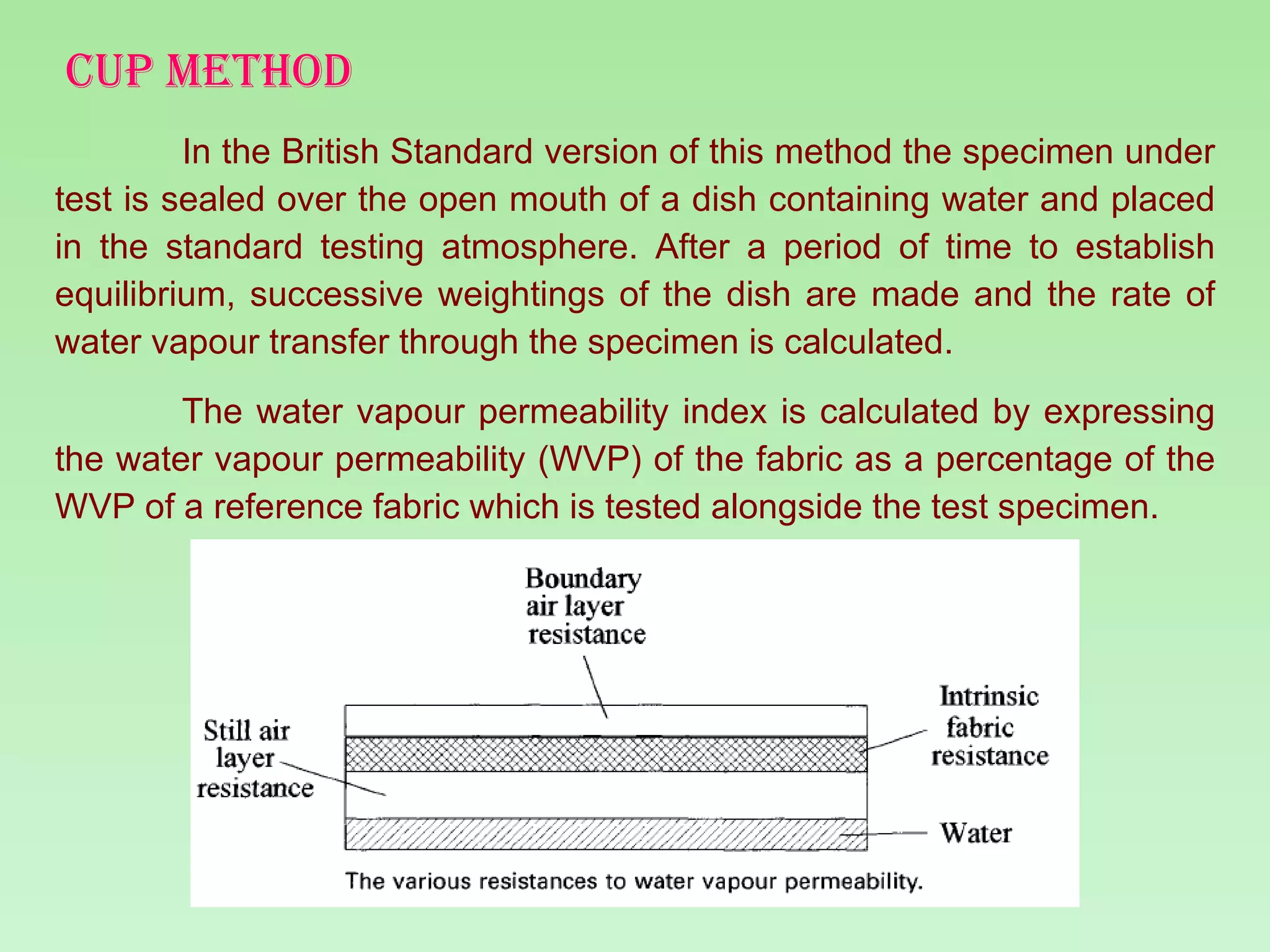

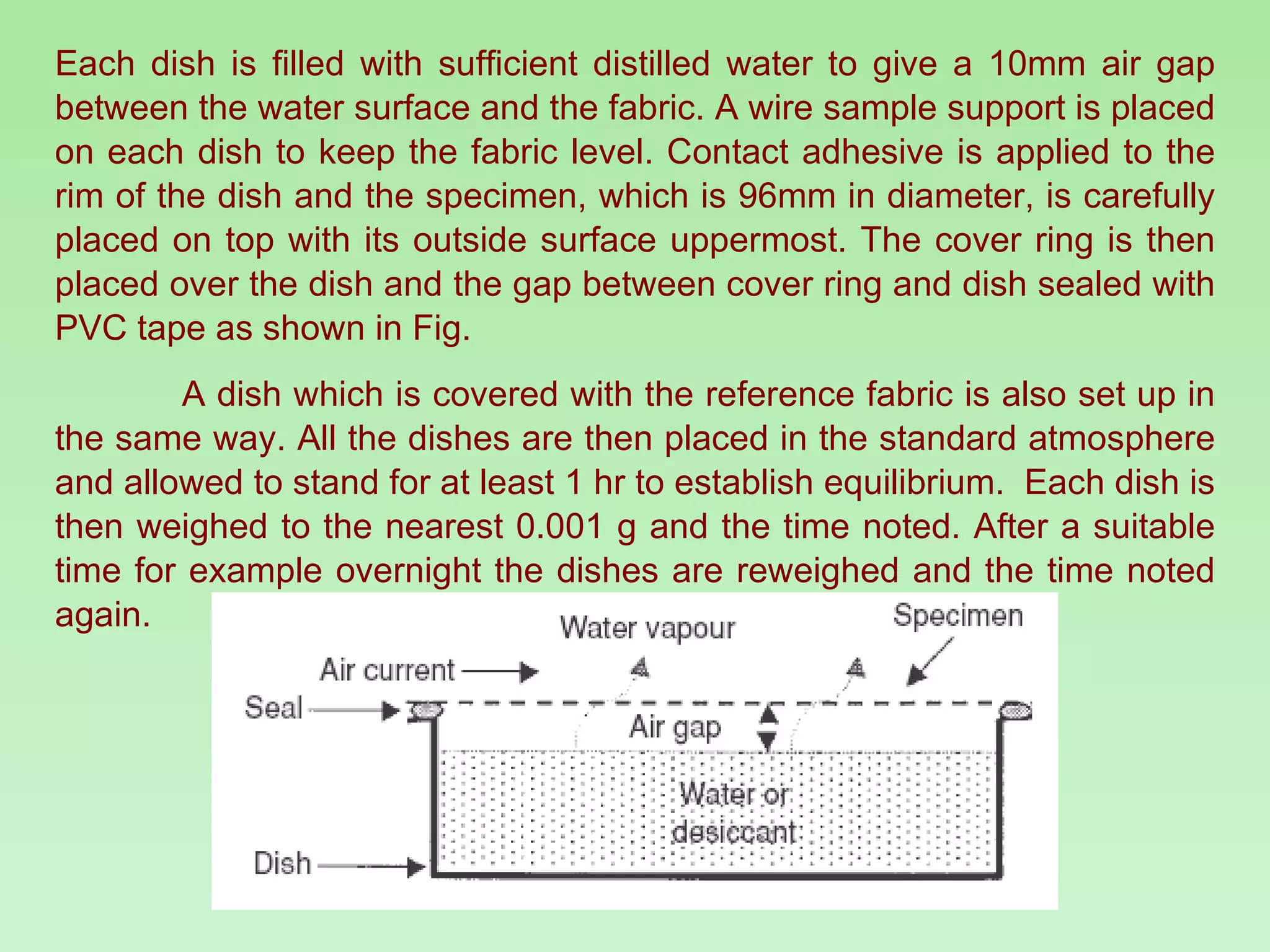

This document discusses various factors that influence thermal comfort in textiles, including heat balance, heat loss mechanisms, insulation, air permeability, moisture vapor permeability, and waterproofing. It defines key terms and describes methods for measuring properties like thermal conductivity, water vapor permeability, and air permeability that relate to a fabric's ability to regulate heat and moisture transfer. The summary focuses on how these physical textile properties influence the thermal comfort of wearers.

![where WVP f is the water vapour permeability of the test fabric and WVP r is the water vapour permeability of the reference fabric. The experiment is sometimes carried out with the cup inverted so that the water is in contact with the inner surface of the fabric [U]. This form of the test tends to give more favorable results for hydrophilic films](https://image.slidesharecdn.com/comfortpropertiesoffabrics-100930061055-phpapp01/75/Comfort-properties-of-fabrics-45-2048.jpg)