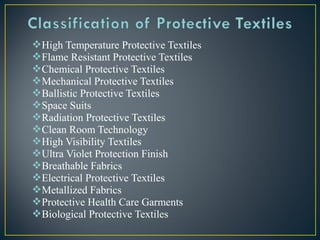

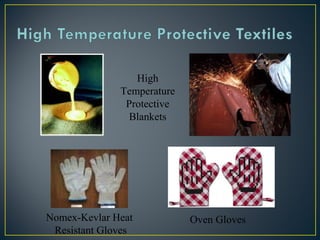

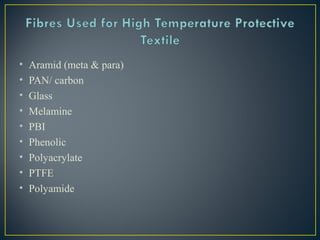

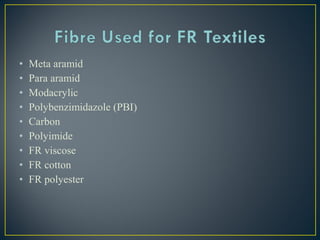

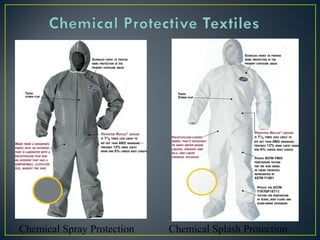

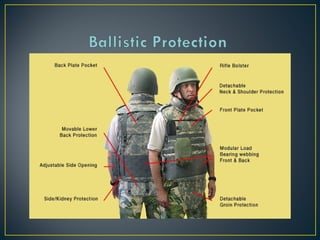

Protective textiles are designed to safeguard individuals from various environmental and industrial hazards such as extreme temperatures, chemicals, and radiation through specialized materials and technologies. They encompass a wide range of applications, including flame-resistant clothing, ballistic protection, and high visibility jackets, with continued innovation driven by safety standards and market demands. The protective textiles industry is expected to see significant growth, with increasing focus on performance, comfort, and environmental awareness.