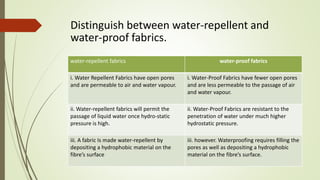

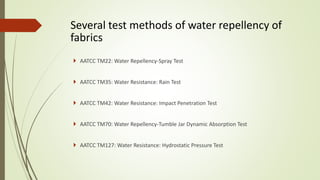

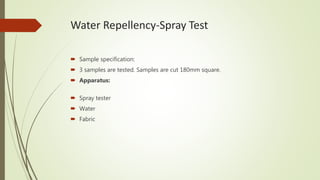

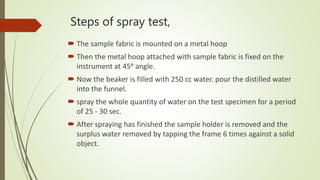

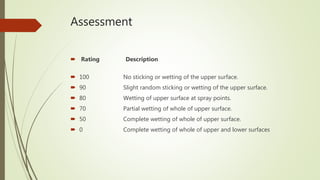

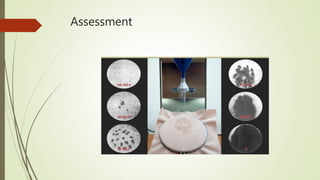

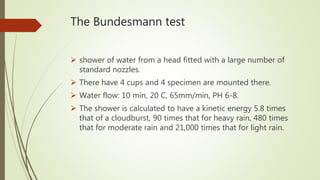

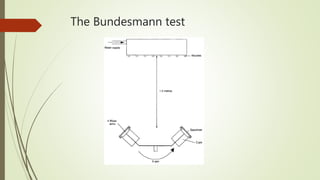

Water repellency and flame retardancy are important textile properties. Water repellent fabrics resist water penetration and allow water to roll off, while waterproof fabrics have fewer pores and are less permeable. Several tests evaluate water repellency, including the spray test where water is sprayed on samples rated based on wetting. The Bundesmann test subjects samples to high-pressure water for 10 minutes to measure penetration and absorption. Flame retardant finishes can save fabrics from fire using compounds of phosphorus, antimony, and boron. The vertical flame test exposes samples to an open flame to evaluate flame retardancy based on after flame and char length. Proper testing ensures textiles have sufficient water repell