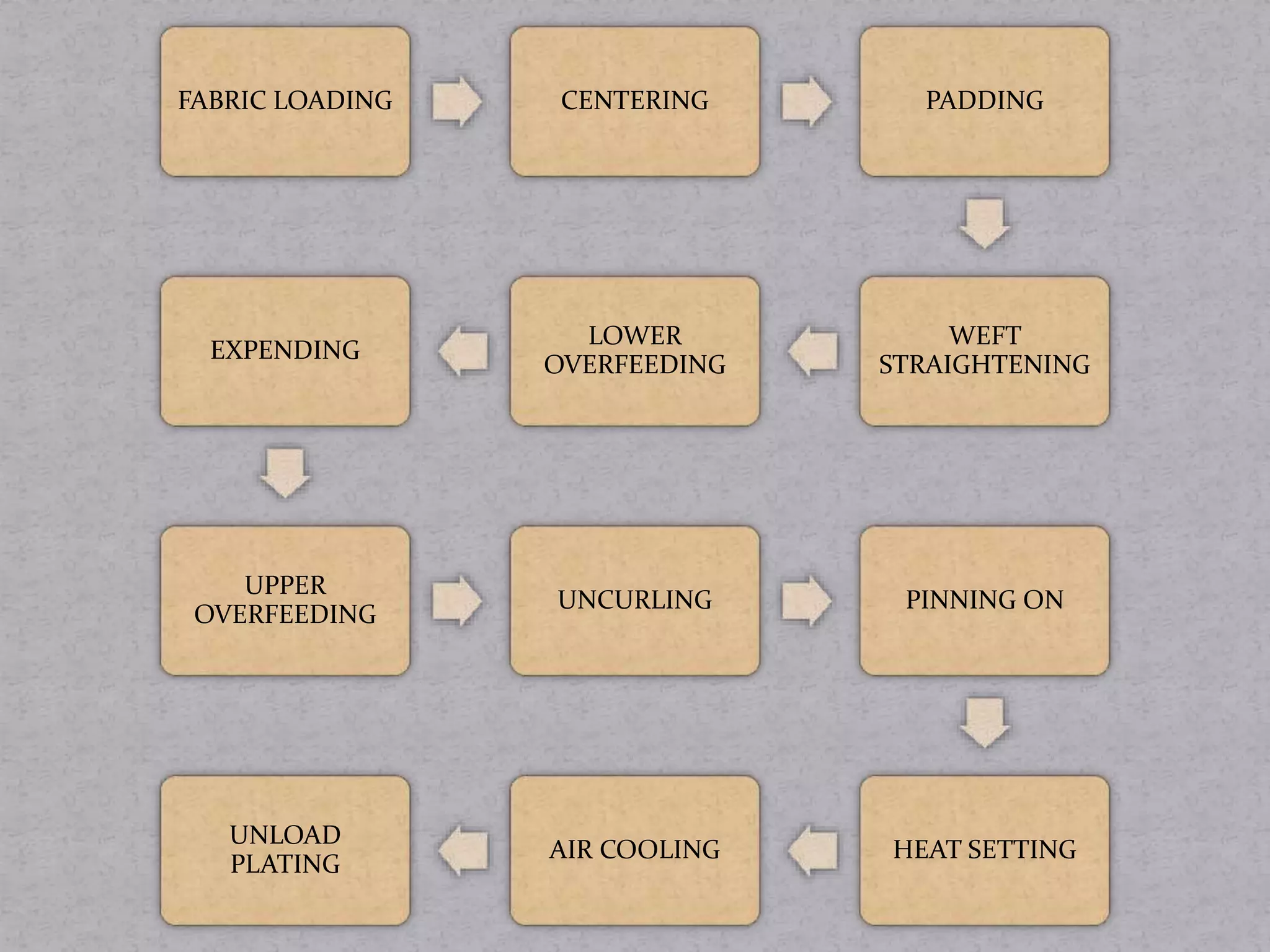

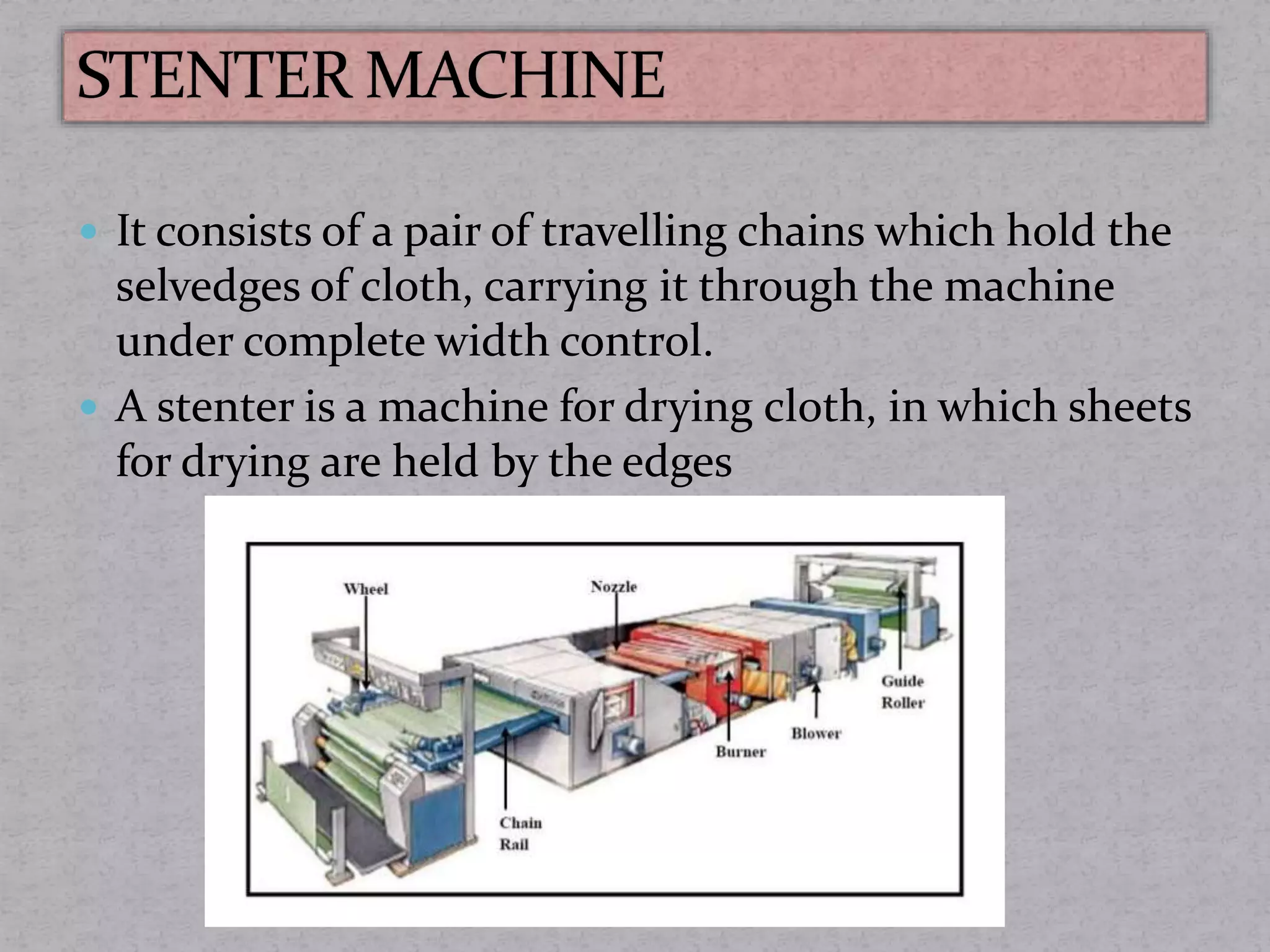

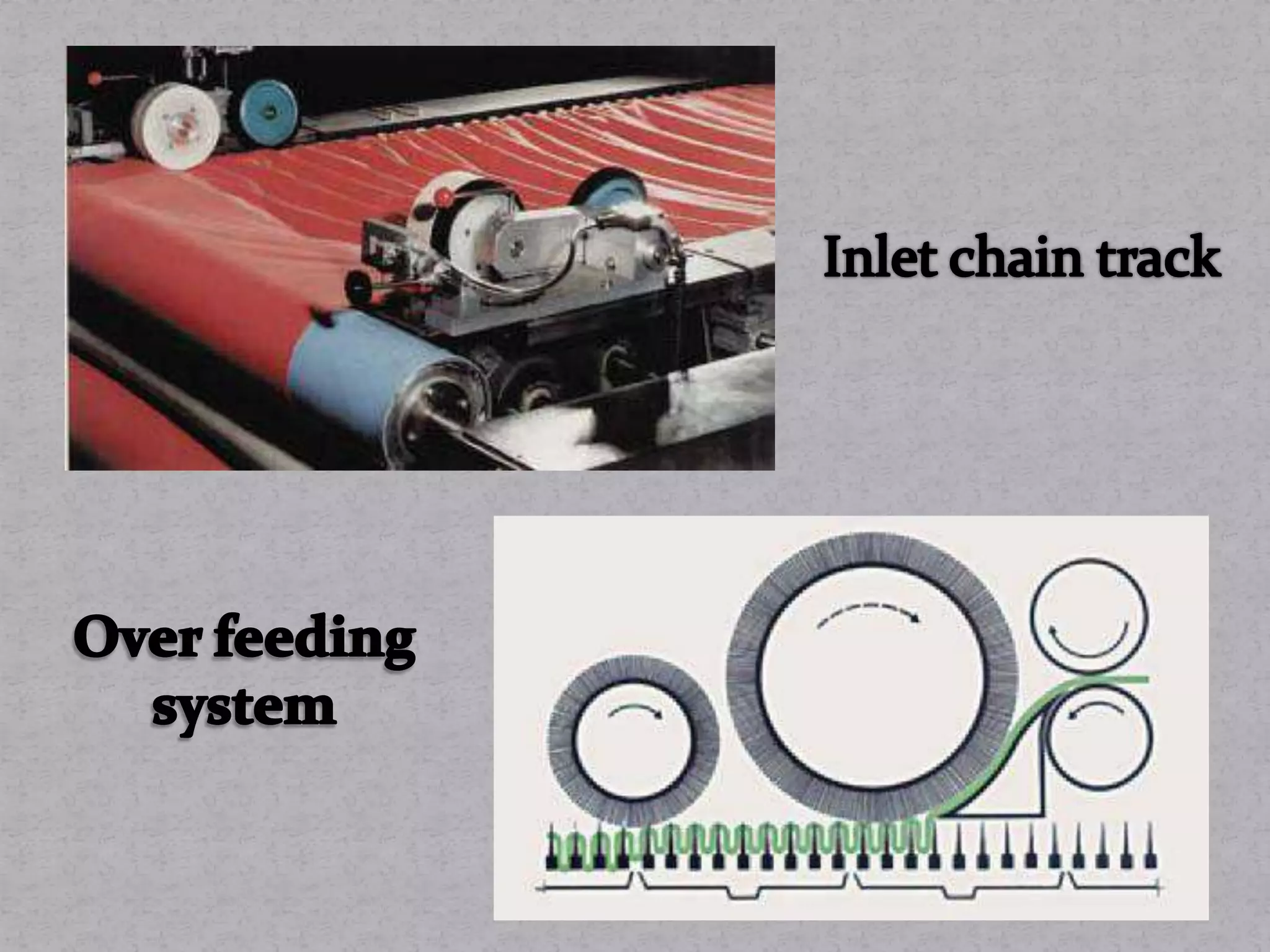

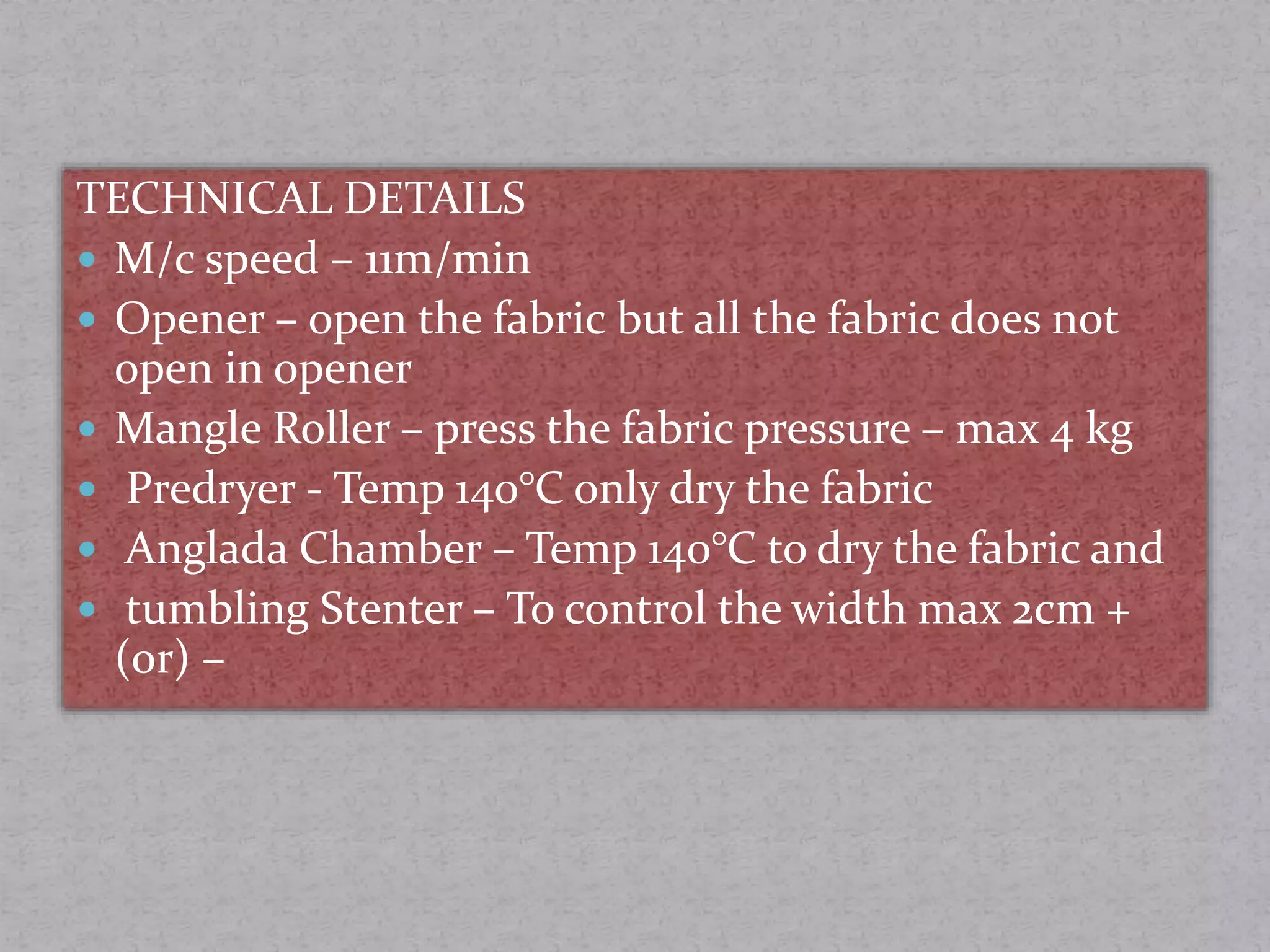

The document discusses various types of machines used in textile processing, including mangles and stenters. It describes mangles as machines that squeeze moisture from fabrics using rollers. There are several types of mangles like ordinary, friction, and water mangles. Stenters are used to dry, heat set, and impart dimensional stability to fabrics. They grip fabric edges and carry the fabric through drying chambers using traveling chains. Hot air is typically used to dry fabrics in stenters. Key components include drying chambers, overfeed systems, and mahlo devices to straighten fabrics.