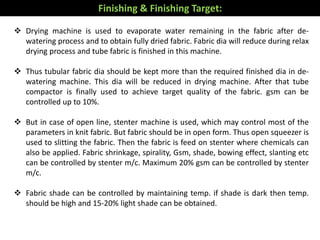

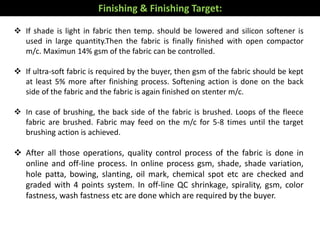

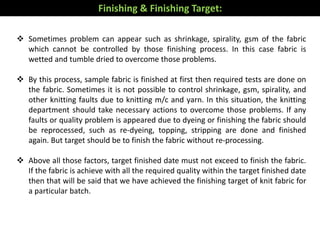

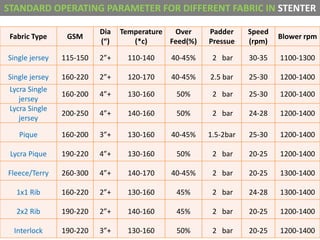

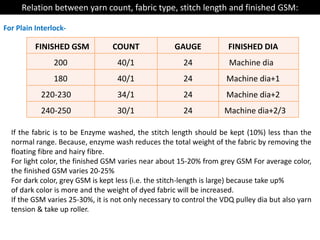

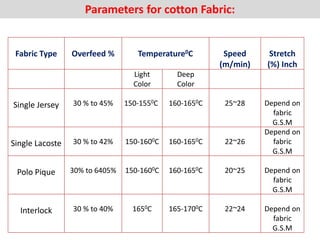

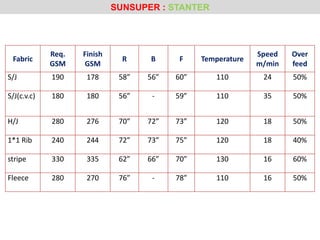

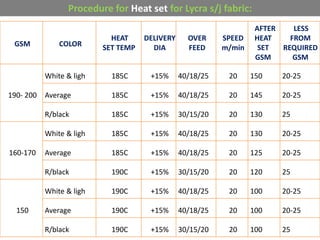

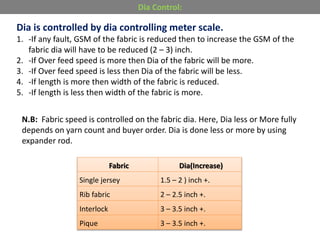

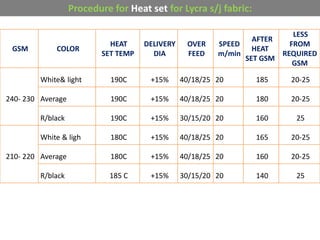

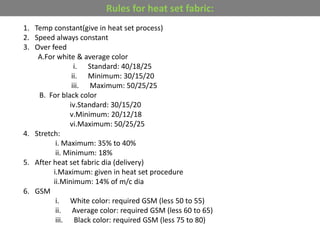

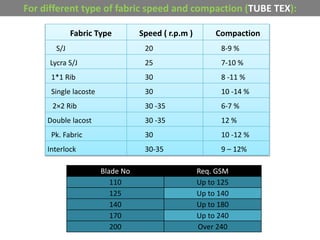

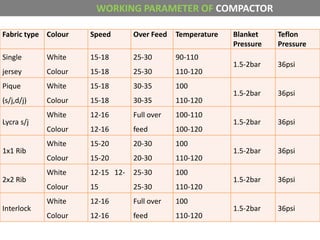

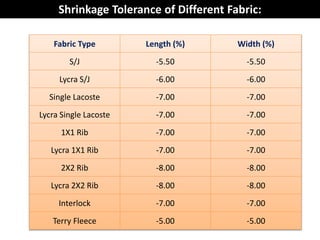

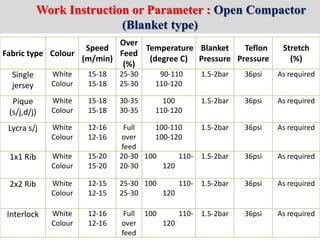

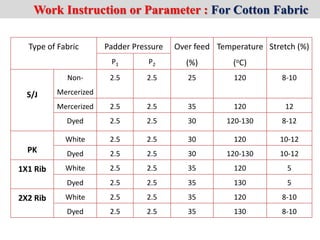

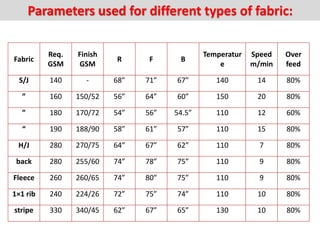

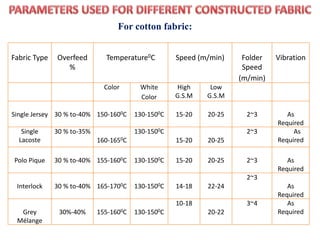

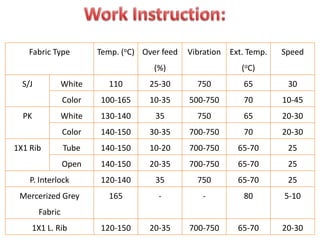

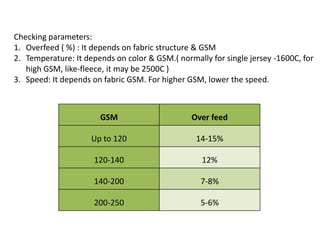

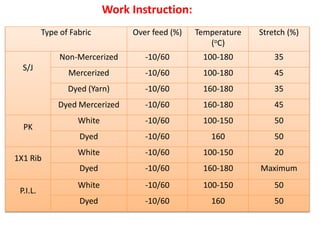

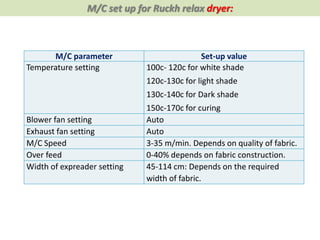

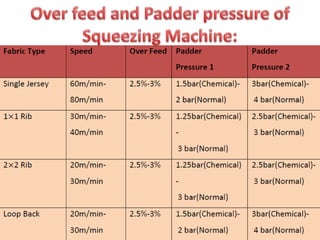

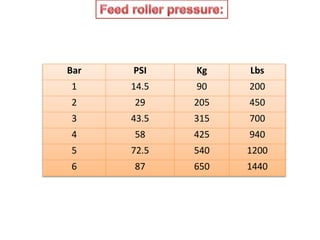

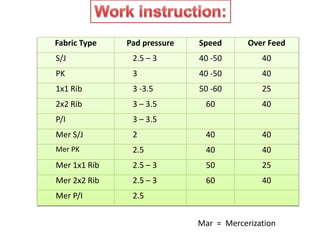

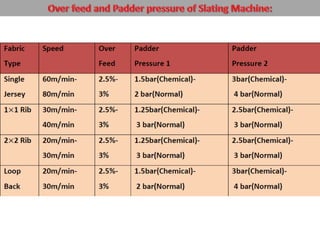

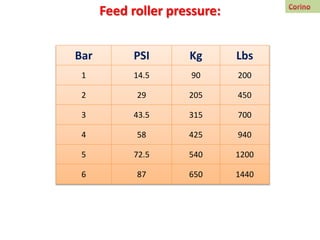

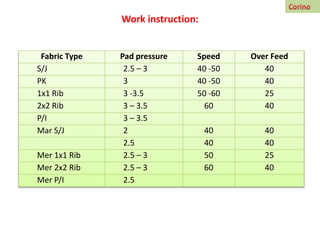

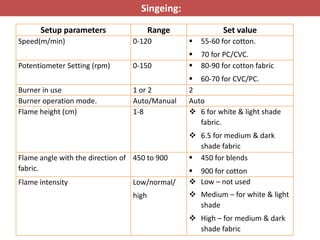

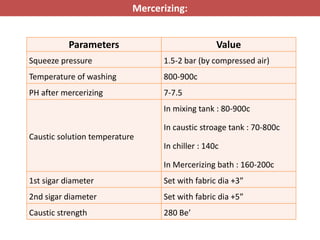

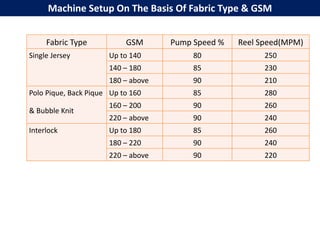

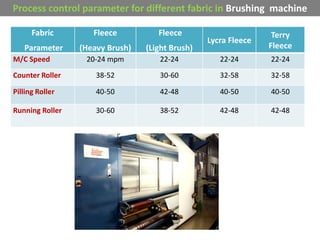

The document details the finishing process of knit fabrics, outlining various parameters influencing fabric quality such as shade, GSM, and shrinkage, vital for meeting buyer requirements. It emphasizes the importance of adjusting finishing techniques like drying, temperature control, and chemical application to achieve desirable fabric characteristics while maintaining cost efficiency. Additionally, factors such as quality control procedures and troubleshooting methods for common fabric issues are addressed, ensuring that the final product aligns with customer specifications and production timelines.