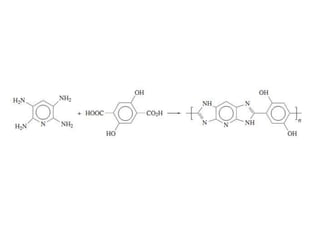

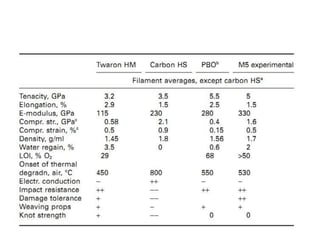

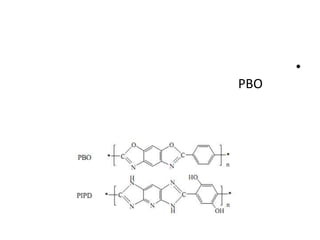

M5 is a new high-performance fiber produced by Akzo-Nobel laboratories. M5 is a rigid-rod polymer called PIPD or poly{2,6-diimidazo[4,5-β:4`,5`-ε]pyridinylene-1,4-(2,5-dihydroxy)phenylene}. M5 fiber is prepared through condensation polymerization of tetraaminopyridine and dihydroxyterephthalic acid using diphosphorus pentoxide. The polymer mixture is then heated and extruded to form brightly blue M5 fibers, which are washed to remove residual chemicals.

![• The polymer is poly{2,6-diimidazo[4,5-β:4`,5`-ε]pyridinylene-

1,4-(2,5-dihydroxy)phenylene} or PIPD](https://image.slidesharecdn.com/pipdorm5rigid-rodpolymer-130418161259-phpapp02/85/Pipd-or-m5-rigid-rod-polymer-6-320.jpg)