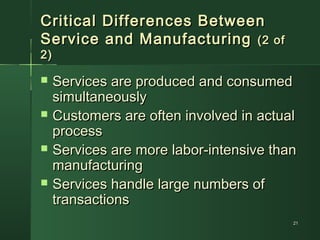

This document discusses total quality in organizations. It covers key topics like systems thinking, manufacturing systems, quality in different business areas like marketing and product design, and critical differences between quality in services and manufacturing. The main ideas are that a systems perspective acknowledges interactions between subsystems, every manager is responsible for quality in their area, and quality is important not just in manufacturing but also in services, healthcare, education and more.