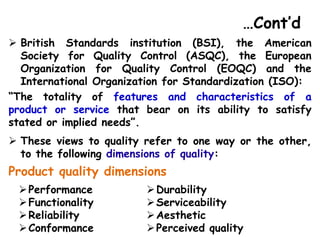

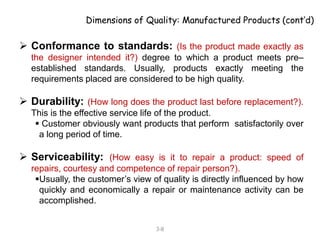

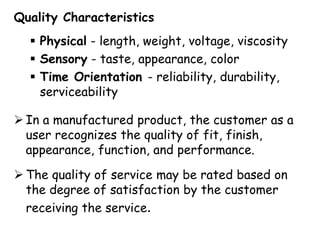

The document outlines an introduction to quality management. It discusses different definitions and dimensions of quality for both products and services. Quality is defined from various perspectives, including fitness for use, conformance to requirements, and meeting customer needs. The evolution of quality management is covered, from inspection and quality control to total quality management and strategic quality. Key aspects of quality include eliminating waste, improving customer satisfaction, and increasing competitiveness.