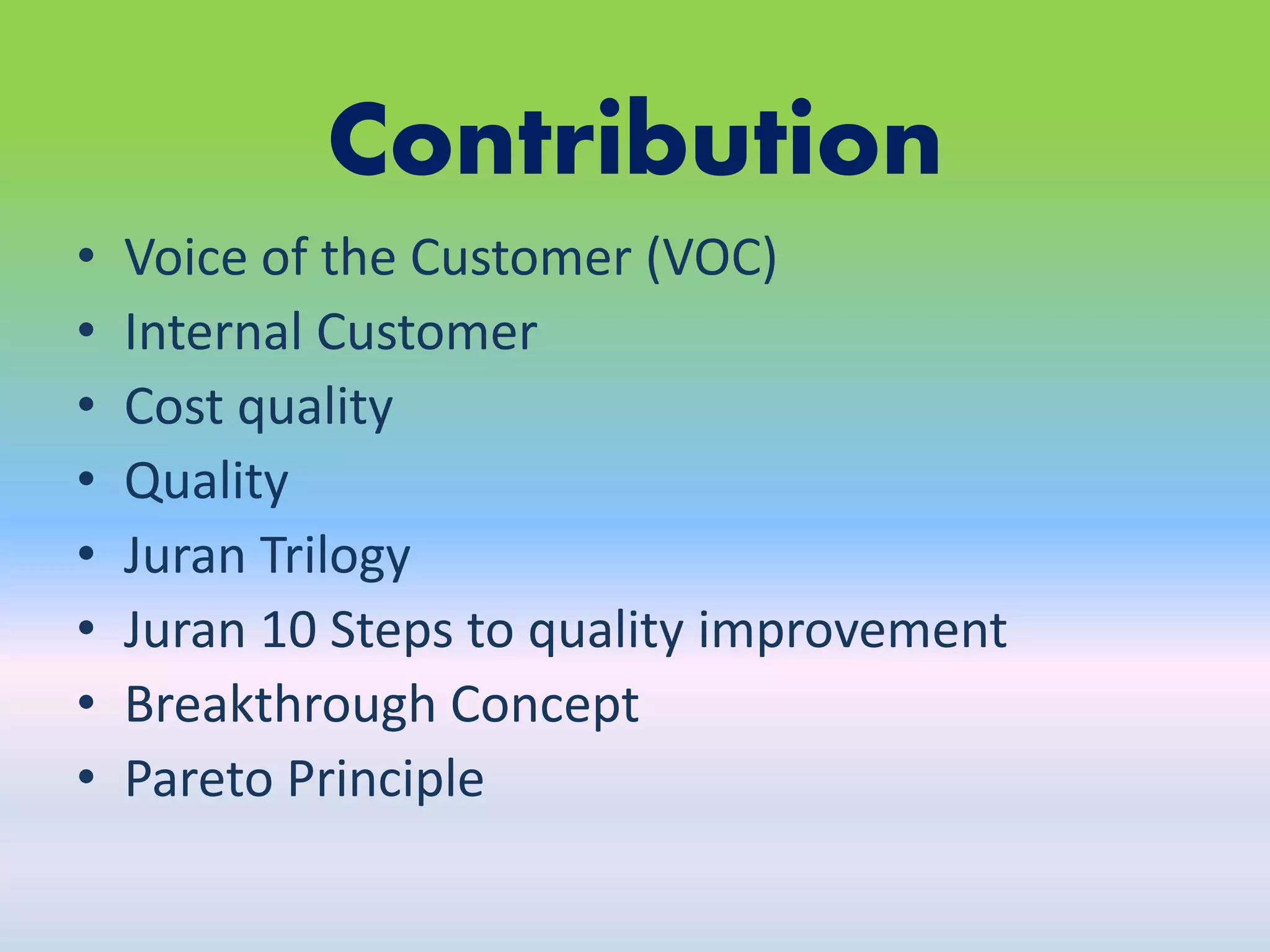

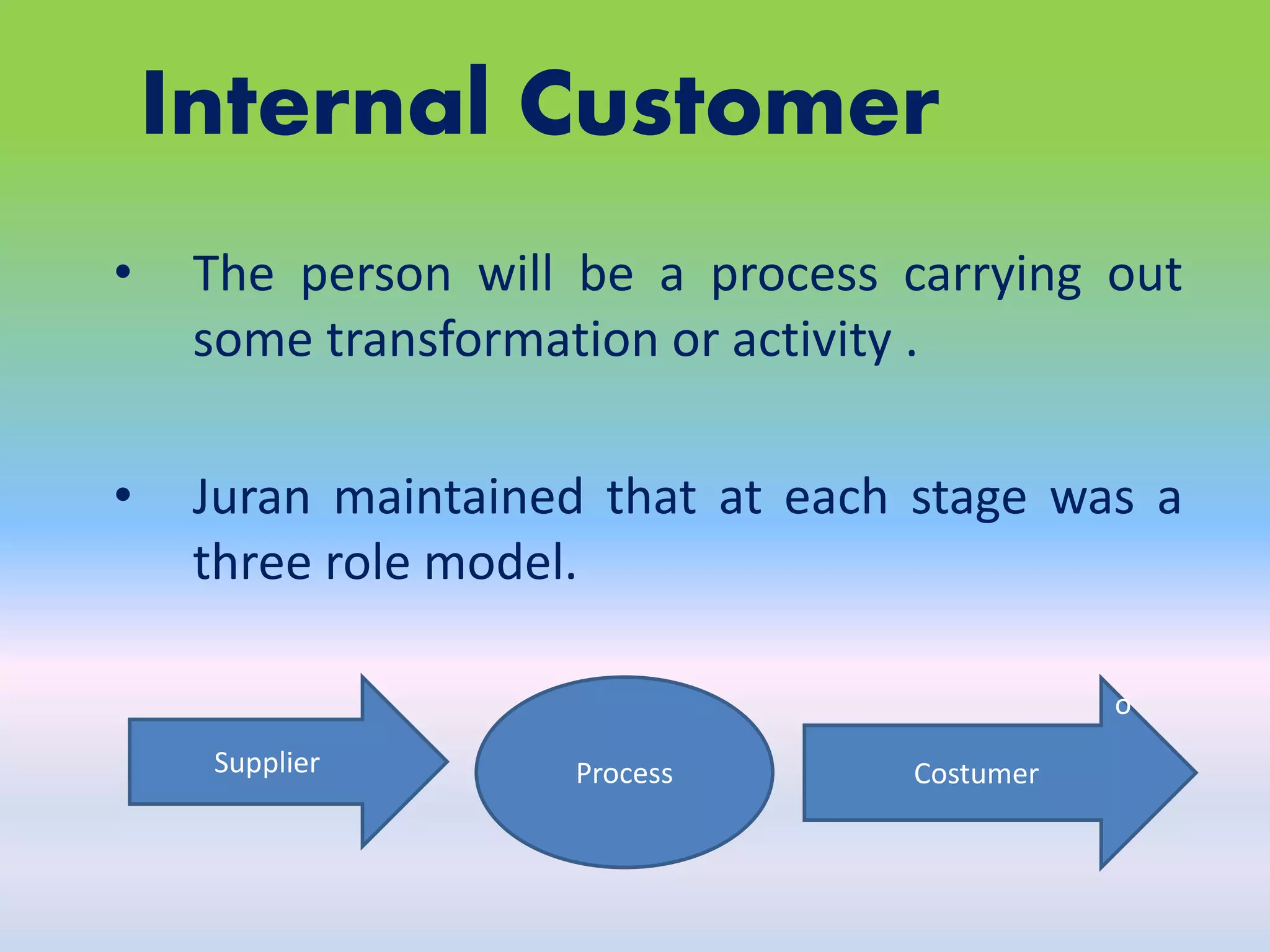

Joseph M. Juran was born in 1904 in Romania and immigrated to the United States. He received degrees in electrical engineering from the University of Minnesota. Juran worked at Bell Labs where he was introduced to statistical process control techniques. He went on to found the Juran Institute and authored several influential books on quality management. Juran is considered a pioneer in quality management, known for developing concepts like the cost of quality, internal customers, quality planning, control, and improvement processes. He emphasized understanding customer needs and introduced the 80/20 Pareto principle to quality improvement.