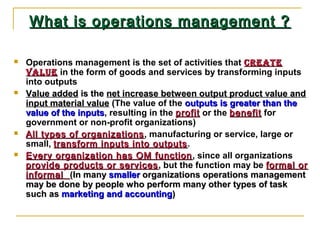

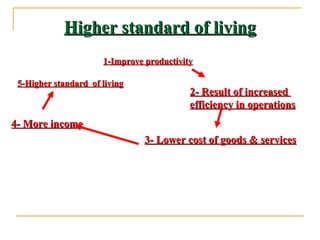

Operations management plays an important role in society by contributing to higher standards of living, better quality goods and services, environmental concern, and improved working conditions. It raises standards of living by increasing productivity and efficiency, which lowers costs and provides more income. It improves quality through initiatives like Six Sigma. It addresses environmental concerns through recycling and pollution reduction. It enhances working conditions by empowering workers and improving job design.