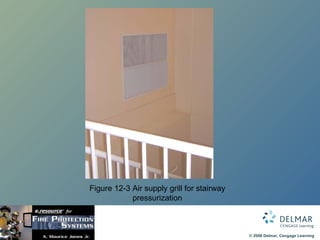

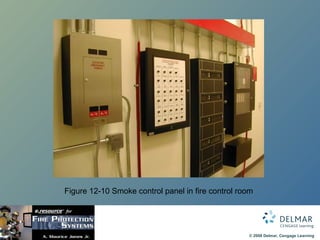

Smoke control and management systems aim to contain smoke and toxic gases to the area of origin using three main methods: containment, exhaust, and opposed airflow. Key goals are to prevent smoke from spreading and to maintain tenable conditions for evacuation. Systems often integrate with fire protection, HVAC, and other building systems. Proper design, installation, and regular acceptance testing are important to ensure effective operation.