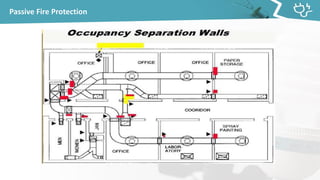

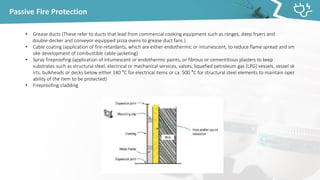

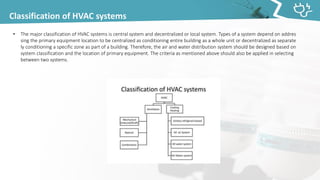

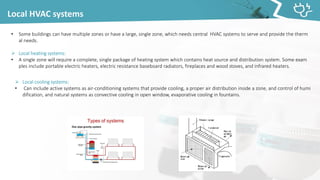

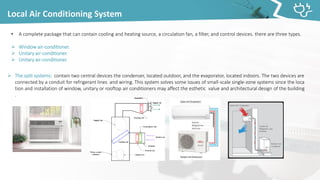

The document discusses electrical works related to firefighting and air conditioning systems. It covers topics such as passive fire protection using firewalls and fire-rated assemblies, active fire protection systems like sprinklers and fire suppression, HVAC system components and classifications of central and local systems. Fire safety elements like fire escapes, hydrants, and escape chutes are also outlined.