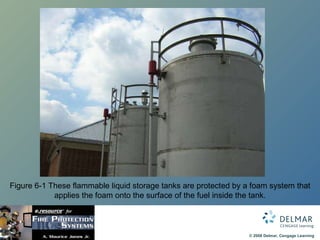

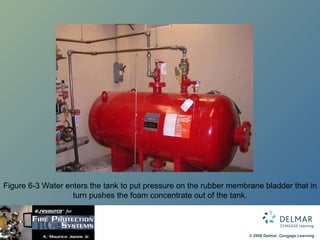

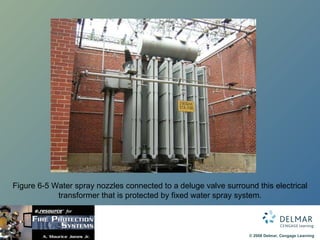

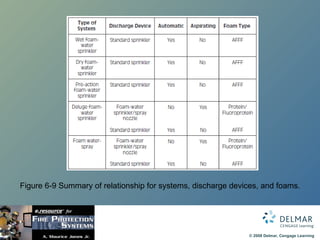

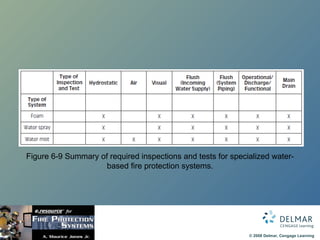

This document discusses specialized water-based fire protection systems as alternatives to standard sprinkler systems. It describes fixed foam, water spray, foam-water, and water mist systems, noting their components, applications, and inspection requirements. These systems provide targeted protection for hazards where sprinklers would be inadequate, such as flammable liquid storage, using methods like foam application or ultra-fine water mist. Proper design, installation, and maintenance are needed to ensure effective performance.