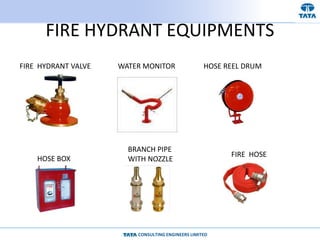

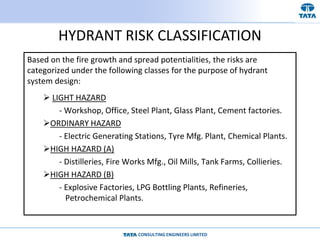

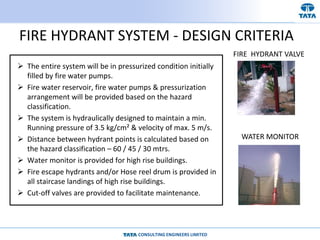

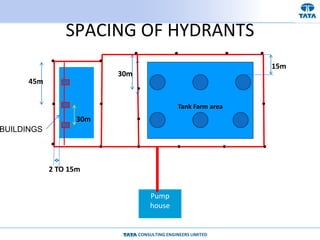

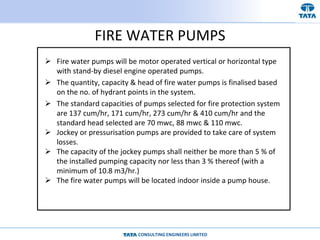

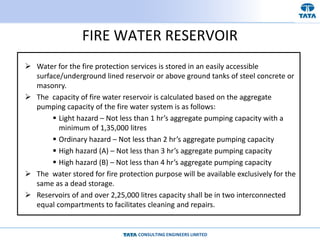

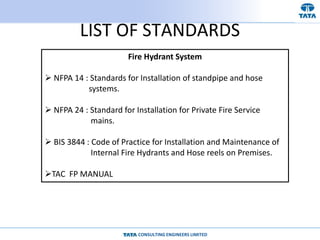

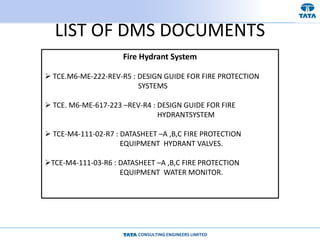

The document discusses fire hydrant systems used for fire protection. It describes the components of a fire hydrant system including hydrants, monitors, hoses, and pipes. It also outlines international and national standards for fire hydrant system design including spacing of hydrants, sizing of pumps and reservoirs, and classification of fire risks. The goal of a fire hydrant system is to provide a reliable water supply for extinguishing fires.