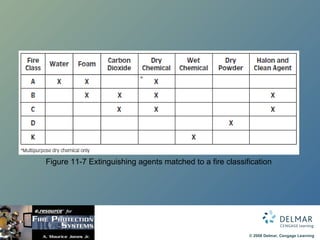

Portable fire extinguishers are intended to quickly suppress small fires. They contain a fixed amount of suppression agent and require trained operators for effective use. Three common types are pumped, stored pressure, and cartridge pressure extinguishers, which use different mechanisms to expel agents matched to specific fire classes, such as water, foam, dry chemicals, or carbon dioxide. Regular inspection, maintenance, and hydrostatic testing are necessary to ensure extinguishers are in proper working order.