Embed presentation

Downloaded 170 times

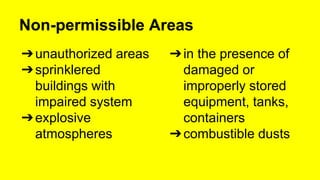

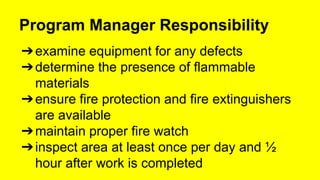

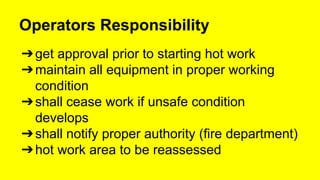

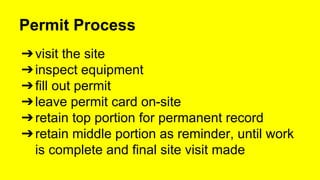

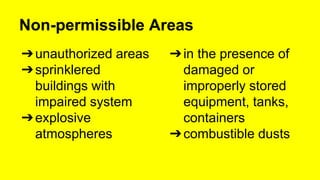

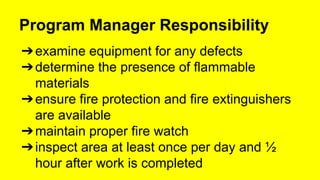

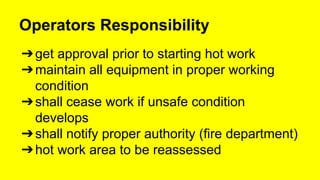

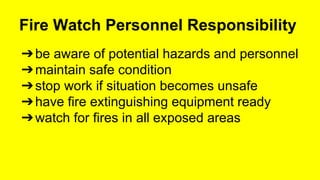

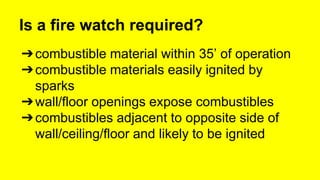

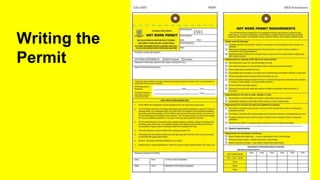

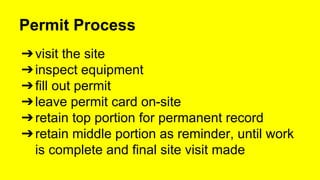

Hot work permits are necessary for various activities like welding and grinding, especially in non-permissible areas or near combustible materials. Responsibilities include ensuring equipment safety, maintaining fire protection equipment, and conducting area assessments before and during hot work operations. The permit process involves site inspection, completing the permit, and retaining documentation throughout the work period.