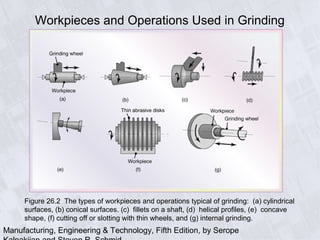

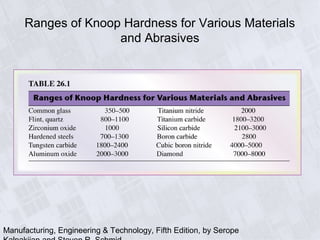

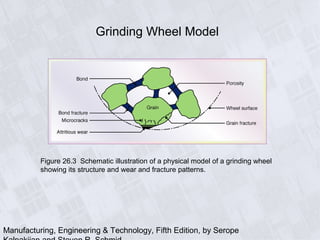

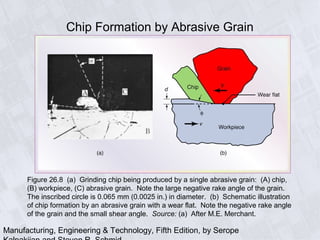

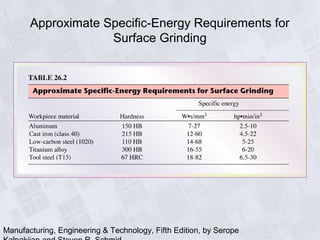

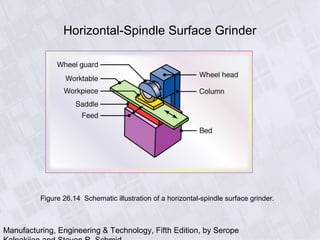

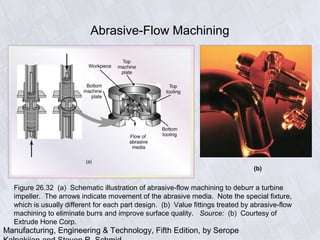

This document discusses abrasive machining and finishing processes. It provides figures and descriptions of various abrasive machining operations including grinding wheels, bonded abrasives, grinding processes like surface grinding and cylindrical grinding. It also covers superabrasive wheels, grinding parameters like speed and feed, and finishing processes like honing, lapping, polishing and chemical mechanical polishing. The document is from a manufacturing textbook and presents information on abrasive processes in a technical manner with many supporting figures and diagrams.