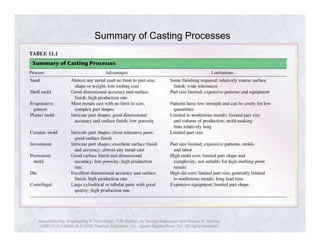

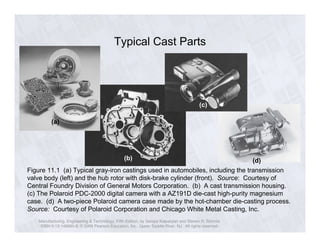

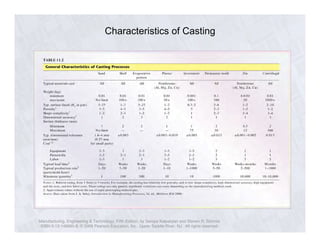

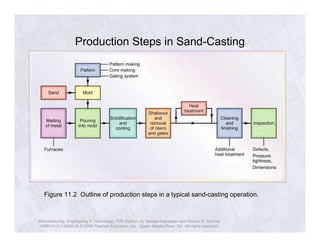

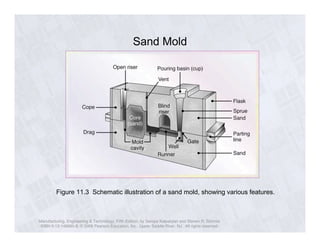

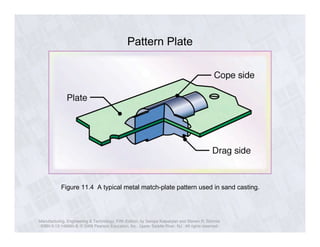

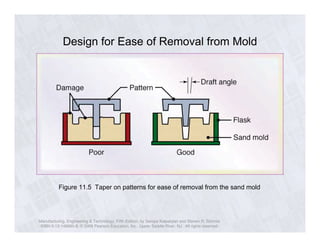

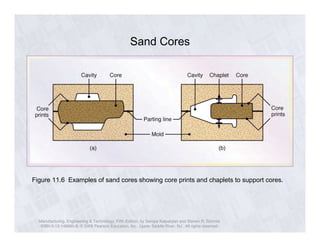

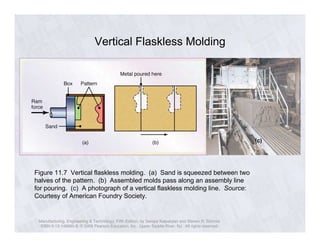

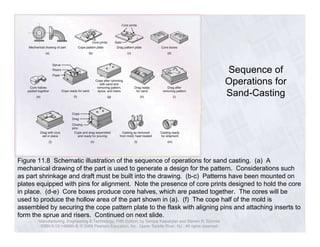

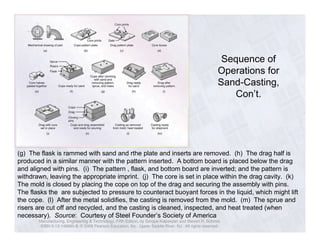

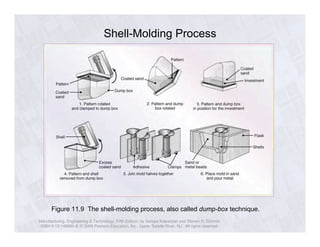

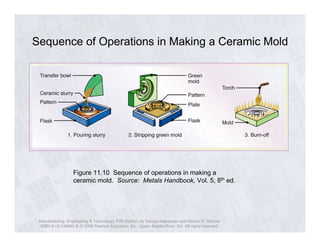

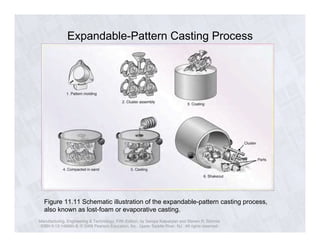

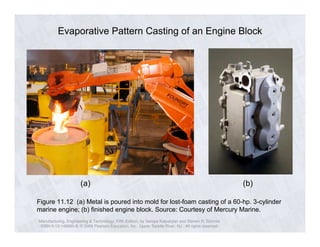

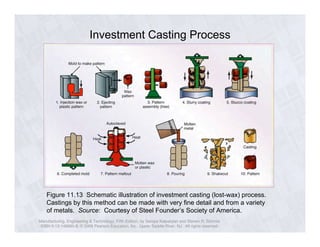

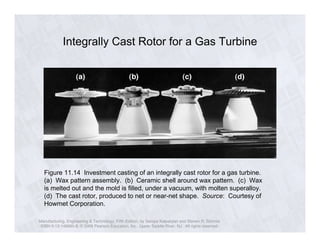

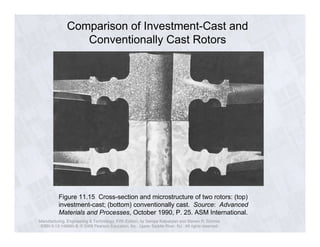

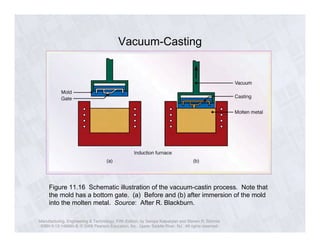

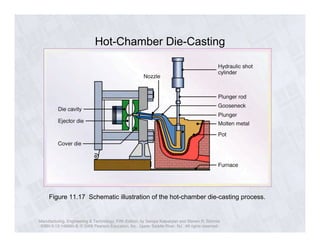

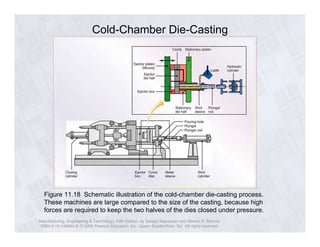

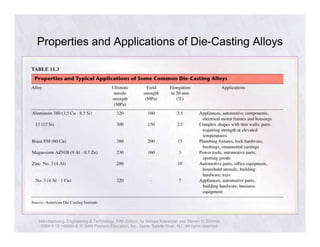

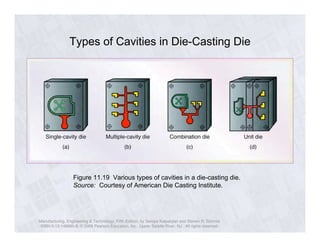

The document describes various metal casting processes and their applications. It discusses sand casting, where a sand mold is used to produce castings. It also covers die casting, a high-pressure process that uses metal dies to produce parts with tight tolerances. Finally, it mentions investment casting (lost-wax process), which can produce castings with fine detail by using wax patterns in ceramic molds. The document contains numerous figures illustrating the different casting methods and example cast components.