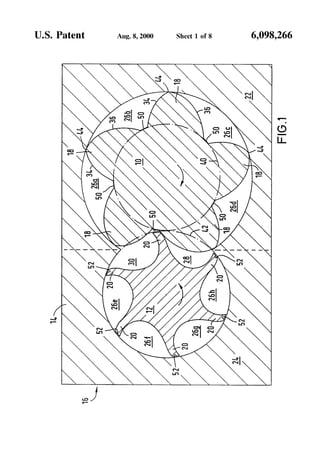

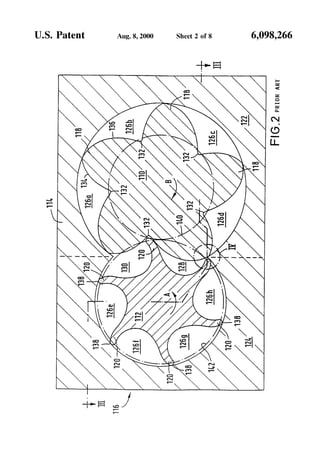

This patent describes a method for producing rotors for screw-type compressors with improved efficiency. Specifically, it involves producing a master rotor with the desired tooth geometry, then performing corrective material removal directly on the negative mold blank rather than on the master rotor. This allows the negative mold to have deepened portions that generate complementary elevated correction regions on the finished rotor. These elevated regions improve the rotor's properties in accordance with the desired optimized geometry. The method allows production of rotors with complex, efficient geometries using a straightforward manufacturing process.

![US006098266A

Ulllted States Patent [19] [11] Patent Number: 6,098,266

Kirsten [45] Date of Patent: Aug. 8, 2000

[54] METHOD FOR THE PRODUCTION OF [56] References Cited

ggagllisEsFggRgcREw'TYpE U.S. PATENT DOCUMENTS

3,787,154 1/1974 Edstom .............................. .. 418/201.3

[76] Inventor: Guenter Kirsten, Erzbergerstrasse 13, 4,614,484 9/1986 Riegler - - - - - - - - - - - -- 418/2013

08451 crimmitschau, Germany 4,636,156 1/1987 Hough et al. ........................ 418/201.3

[21] Appl' NO‘: 08/860,698 FOREIGN PATENT DOCUMENTS

_ 1704236 5/1971 Germany .

[22] PCT Filed: Jan. 17, 1996 3448025 5/1986 Germany .

3506475 8/1986 Germany .

[86] PCT No.: PCT/EP96/00175 3903067 8/1990 Germany .

3271587 12/1991 Japan .............................. .. 29/888.023

§ 371 Date: Jul‘ 9’ 1997 Primary Examiner—John J. Vrablik

§ 102(6) Date: JuL 9’ 1997 Attorney, Agent, or Firm—Diller, Ramik & Wight, PC

[57] ABSTRACT

[87] PCT Pub. No.: WO96/22870

The invention is directed to a method for the production of

PCT Pub. DatezAug. 1, 1996 rotors (10) for screW-type compressors (16) and to rotors

_ _ _ _ _ (10) to be produced according to said method. To allow the

[30] Forelgn Apphcatlon Pnonty Data use of a straightforward manufacturing method for the

Jan. 26, 1995 [DE] Germany ........................... 195 02 323 production of rotors (10) of a complex geometry, a method

[51] Int. c1.7 ..................................................... B22D 25/02 15 proposed Wheel“, dunng the productl?“ of the neganve

52 U S C] 29 527 1_ 29 527 5_ 29 888 023 mold, material is removed from a negative mold blank to

[ ] ' ' ' """"""""" " / ' ’ / ' ’ / ' generate correction regions of a rotor (10).

[58] Field of Search ........................ 418/2013; 29/5271,

29/5275, 530, 888.023 4 Claims, 8 Drawing Sheets](https://image.slidesharecdn.com/053c2731-e92c-4d9c-90b0-84b775ea35b1-160525115914/85/US6098266-1-1-320.jpg)