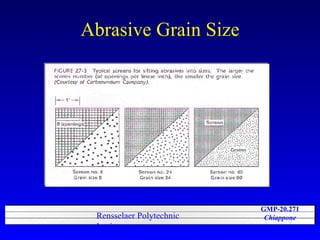

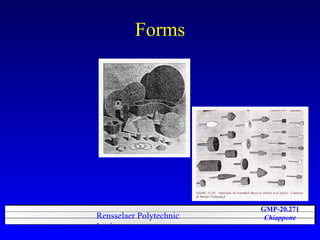

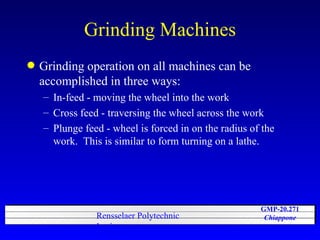

The document discusses abrasive machining processes. It describes how abrasive machining uses small cutting edges on abrasive particles to remove material. Common abrasives include natural materials like sand and man-made materials like silicon carbide and aluminum oxide. Parts that can be machined include hard metals and parts requiring close tolerances. Grinding is one process that uses bonded abrasive wheels to cut materials. Precise tolerances of +/- 0.0001" can be achieved through grinding.