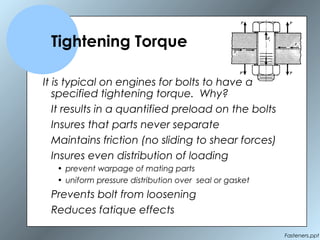

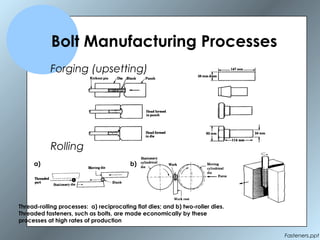

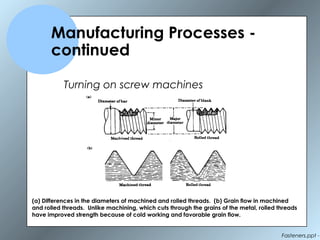

The document discusses various topics relating to threaded fasteners including types of fasteners, materials and grades, tightening torque, and manufacturing processes. It notes that a Boeing 747 uses around 2.5 million fasteners including 70,000 titanium bolts costing $150,000. Tightening bolts to the specified torque is important as it ensures an even load distribution and prevents parts from loosening or failing. Common bolt manufacturing methods include forging, rolling, and thread rolling which strengthen the material.