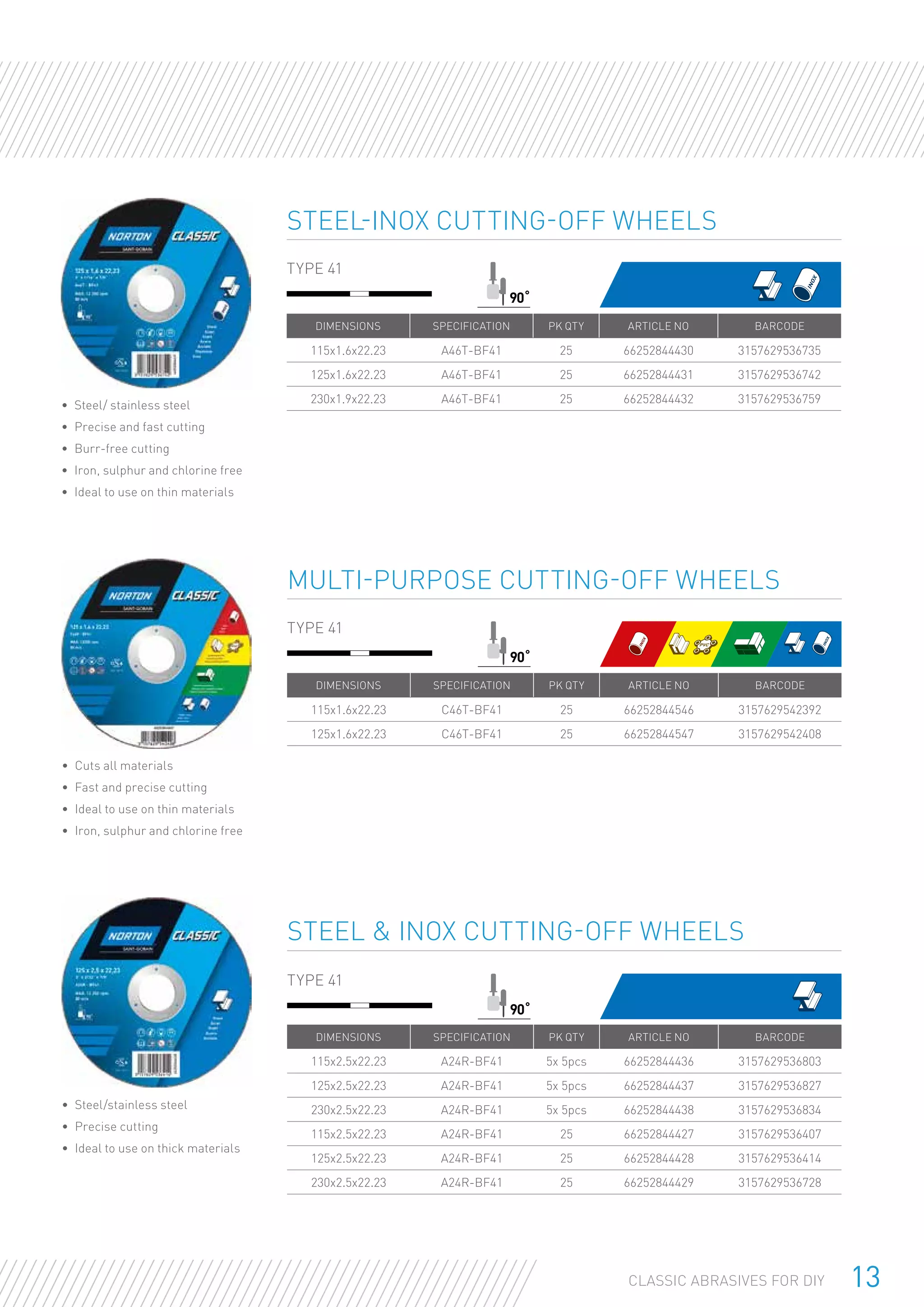

The document details Norton, a leading brand under Saint-Gobain Abrasives, known for its comprehensive range of innovative and technologically advanced abrasive solutions. It outlines Norton's commitment to quality, sustainability, and safety in manufacturing, alongside a user-friendly brochure for consumers looking to efficiently order and utilize their products. The brochure covers product types, ordering information, and sustainability initiatives that minimize environmental impact during production and use.