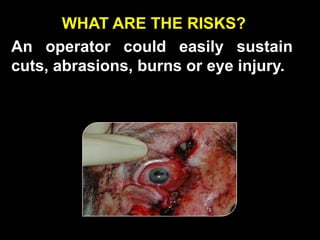

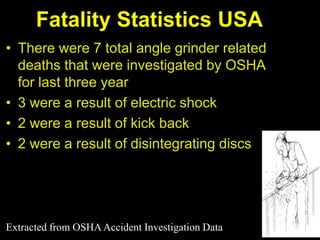

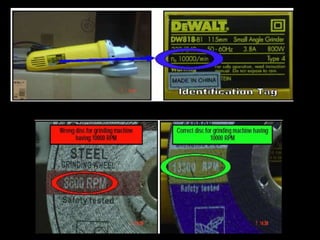

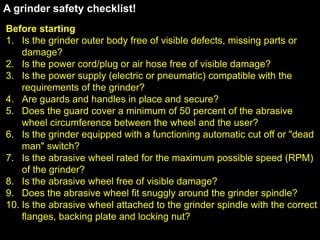

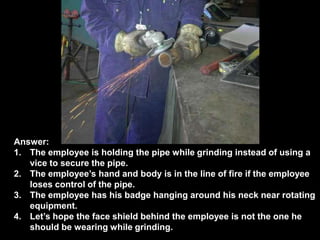

The document provides information about angle grinder safety. It describes how angle grinders are commonly used power tools that can pose serious hazards. It discusses typical injuries such as cuts, burns and eye injuries that can occur from sparks and debris or disc failure. The document also presents a case study of a fatal accident caused by an operator removing the safety guard and using an improperly sized disc. It emphasizes the importance of using proper personal protective equipment, inspecting the tool and disc, and securing the workpiece.